Dynatect’s Ro-Lab division introduces three new high-performance elastomeric products for construction, paving, and roadbuilding equipment ideal for OEMs, distributors, and end-users. These include polyurethane track pads, polyurethane pipe guides, and rubber rod wipers.

Polyurethane Track Pads

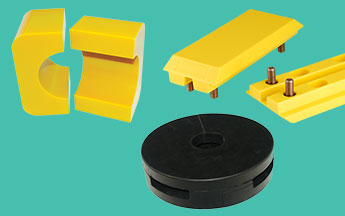

Track pads frequently bought as aftermarket add-ons for milling machines, excavators, cranes, dozers, pavers, curb-and-gutter machines, and trenchers. Abrasion-resistant track pads enable asphalt paving equipment to travel over existing pavement without damaging it. The primary purpose is to protect the surface they travel on from damage. Milling machines are the most abrasive application for track pads, requiring regular change-out of worn parts.

Polyurethane track pads are popular because they wear significantly better (2-3X) compared to rubber, thus is a preferred choice when lower maintenance and downtime is required. Dynatect uses a patented urethane chemistry designed for its superior abrasion resistance and excellent dry sliding abrasion.

Dynatect’s manufacturing process utilizes metering machines ensure precise resin and curative delivery. The resulting track pads perform substantially better than market standard urethane products and help reduce downtime with fewer change-outs.

More information on track pads.

Polyurethane Pipe Guides

Pipe guides are urethane parts that guide the drill pipe into the ground, and act as a buffer when the drill pipe spins to hold it in place. Pipe guides are wear parts that must be replaced between one or more bore cycles. Dynatect’s pipe guides have been formulated, designed, and field tested to prevent the drill pipe from jumping around, causing shake and rattle during operation.

The pipe guide operates in temperature extremes so flexibility at all conditions is critical, including an operating range of -40° F to +120° F. The pipe guide is typically covered in grease and is exposed to water/drilling mud. Thus, environmental resistance is critical. Dynatect’s unique polyurethane formulation resists heat build-up or melting, providing a consistent support surface for the drill pipe.

More information on pipe guides.

Rubber Rod Wipers

Rod wipers are used in directional/horizontal drilling machines to clean the drilling shaft and remove mud/debris as it is pulled back. While this is a consumable product, replacement cycles can be minimized with wipers specifically designed to withstand mud abrasion. Dynatect rod wipers are proven to have superior field performance.

Rod wipers come in two styles (unreinforced and reinforced). Dynatect produces several different sizes of both the unreinforced and reinforced sizes.

More information on rubber rod wipers.