Check out Dynatect’s feature article on ManufacturingTomorrow.com!

Often robots have enough mass, speed, and inertia that any contact with humans creates the primary hazard; process driven hazards, for example sparks/splatter and UV light in a robotic welding process becomes the secondary hazard.

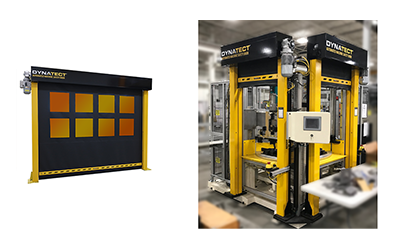

Manufacturing industries continue a strong trajectory of automation, especially for applications with dangerous processes. Even with automation, processes may still contain a human “interaction point” that requires additional safety and/or engineering controls for machine operator safety. When that interaction point is intermittent or exceptional, light curtains have been the traditional protective device. Their advantage includes allowing fast operator access without having to manually open a protective door. Light curtains, however, have limitations as they are not physical barriers ultimately increasing required space dedicated to safety. Additionally, they can be falsely triggered by the machine operator or other activity introducing further inefficiencies to an automated process. As a result, there is an increasing demand for the solid protection of automated high-speed doors which allow fast, periodic access without being victim to false triggers.

Read the rest of the article here

Manufacturingtomorrow.com/article/2021/07/protecting-workers-from-manufacturing-hazards/17345