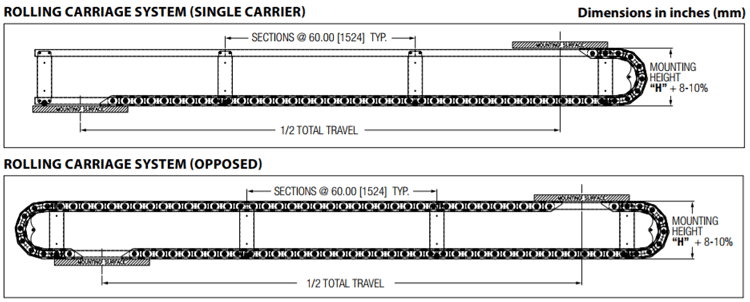

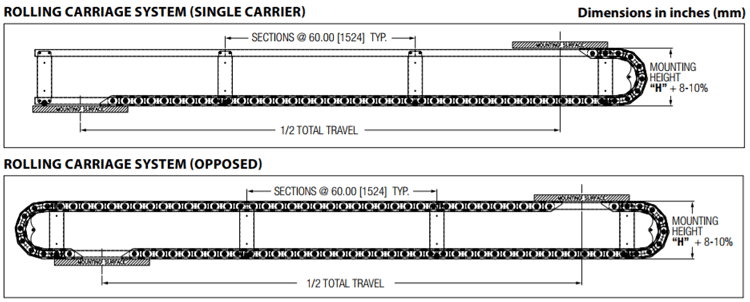

Rolling Style Carriage

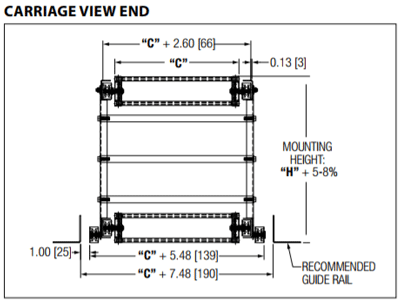

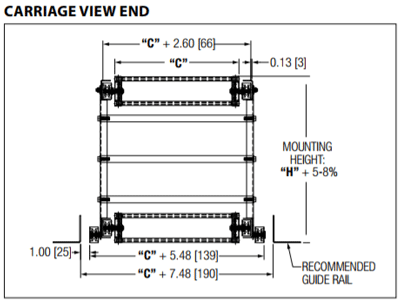

Rolling carriage support systems consist of rollers, conveyor supports and a moving rail framework that supports the carrier throughout the complete length of travel. The entire system is guided by channels that ensure accuracy and dependability, even at extremely high loads and velocities. The system can be self-guiding for travels under 50 feet. Guide channel required for travels over 50 feet. Depending on mounting location, a guide channel is recommended for all lengths of carrier travel to prevent outside interference.

Rolling carriage support systems consist of rollers, conveyor supports and a moving rail framework that supports the carrier throughout the complete length of travel. The entire system is guided by channels that ensure accuracy and dependability, even at extremely high loads and velocities. The system can be self-guiding for travels under 50 feet. Guide channel required for travels over 50 feet. Depending on mounting location, a guide channel is recommended for all lengths of carrier travel to prevent outside interference.

Features/Benefits:

- Lightweight: Reduced tow forces vs. conventional carriage systems

- Modular: Easy to add/remove length

- Easy assembly: Most components are bolted together

- Quiet: Molded nylon wheels used for low noise

- Track drives/returns carriage without use of cable

- Can be used with both metal and plastic carrier systems

Rolling Carriage Layout Drawings

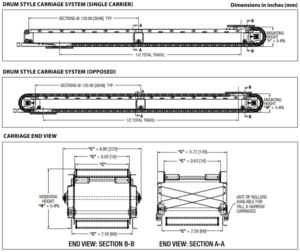

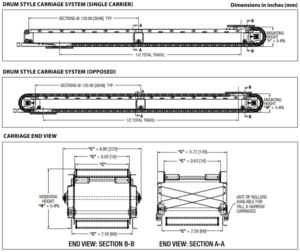

Drum-Style Carriage

Carriage support systems consists of a moving framework that has major rollers (drums) at each end and intermediate conveyor supports between the major rollers, which support the cable carrier for the complete length of travel.

Carriage support systems consists of a moving framework that has major rollers (drums) at each end and intermediate conveyor supports between the major rollers, which support the cable carrier for the complete length of travel.

The entire system rolls on “C” -channels on the floor (or a bridge).

Single carrier carriage systems require a return cable assembly. For use with metal carriers only.

Features/Benefits

- Robust-designed for heavy-duty operation with steel carriers

- Modular: Easy to add/remove length

- Easy assembly: Most components are bolted together

Layout Drawing Click image to view larger or download as PDF

Rolling carriage support systems consist of rollers, conveyor supports and a moving rail framework that supports the carrier throughout the complete length of travel. The entire system is guided by channels that ensure accuracy and dependability, even at extremely high loads and velocities. The system can be self-guiding for travels under 50 feet. Guide channel required for travels over 50 feet. Depending on mounting location, a guide channel is recommended for all lengths of carrier travel to prevent outside interference.

Rolling carriage support systems consist of rollers, conveyor supports and a moving rail framework that supports the carrier throughout the complete length of travel. The entire system is guided by channels that ensure accuracy and dependability, even at extremely high loads and velocities. The system can be self-guiding for travels under 50 feet. Guide channel required for travels over 50 feet. Depending on mounting location, a guide channel is recommended for all lengths of carrier travel to prevent outside interference.

Carriage support systems consists of a moving framework that has major rollers (drums) at each end and intermediate conveyor supports between the major rollers, which support the cable carrier for the complete length of travel.

Carriage support systems consists of a moving framework that has major rollers (drums) at each end and intermediate conveyor supports between the major rollers, which support the cable carrier for the complete length of travel.