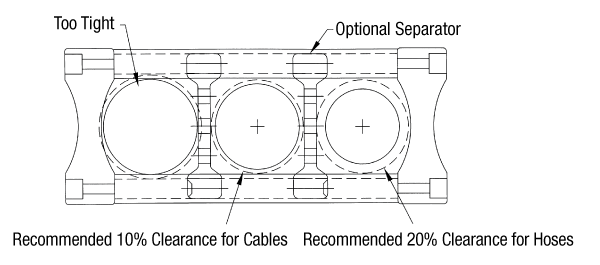

Recommended cable/hose placement

The cables/hoses must not be twisted and should be free of kinks or other irregularities. When stacking cables/hoses, care should be taken to ensure enough slack has been provided to allow cables/hoses to travel freely on top of one another.

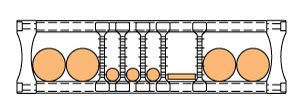

Ideal– Cable/hose down centerline of carrier (achieved by machined cross bars)

Potential Problems: – Cable/hose too close to outer or inner diameter

Correct:

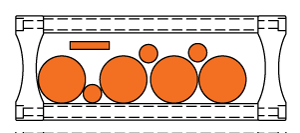

Incorrect:

The stacking or direct side-by-side placement of cables and hoses with large cross-sectional differences is not recommended.

We recommend a minimal 10% clearance for each cable overall diameter and 20% clearance for each hose overall diameter. 60% total cavity fill optimal.

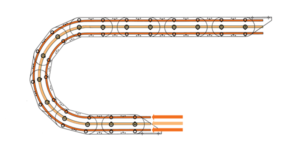

Make certain that the cable/hoses are laid into the carrier “twist-free”.

Cables/hoses supplied in rolls or on roll reels should be unrolled, not pulled sideways or off the top of the coil.

Correct:

Incorrect:

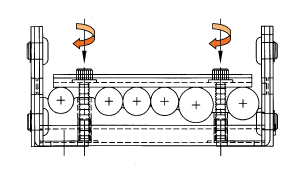

All cables and hoses* should be secured at both the fixed and moving ends. Please do not pinch the cables/hoses excessively while clamping the ends in place.

*Except in applications with high pressure hydraulic hoses, we recommend clamping at moving end of the carrier only. See our cable clamping page.