What is a Ball Screw?

A ball screw is a mechanical device used to convert rotational motion into linear motion. It is composed of a threaded shaft, a nut, and a series of ball bearings. The ball bearings are housed in the nut, which is then mounted on the threaded shaft. As the threaded shaft rotates, the ball bearings move along the thread, causing the nut to move linearly along the shaft.

The ball screw is known for its high accuracy, high efficiency, and low friction. It is an essential component in many high-precision applications, including machine tools, robotics, and aerospace systems.

How Do Ball Screws Work?

With a regular nut and bolt, turning the nut makes it go up or down the bolt (linear motion). A ball screw works similarly, but with much less friction. Visualize a threaded rod with a nut, but instead of the threads rubbing together, there are ball bearings rolling in grooves on between the rod and the nut. The ball bearings roll instead of slide, requiring less energy. When you turn the rod or the nut, the balls keep circulating on a continuous path within the nut, allowing for smooth, precise linear motion with minimal friction. The ball return system routes the balls from one end of the travel path back to the beginning in a continuous circulation. The direction of linear motion (forward or reverse) depends on the whether the screw is rotated clockwise or counter-clockwise. Wipers on the sides help seal out dust and dirt to maintain smooth operation.

Lead Screw vs. Ball Screw

A lead screw is a threaded shaft that is used to convert rotary motion into linear motion. It is similar to a ball screw, but instead of using ball bearings, it uses sliding friction to move the nut along the shaft. Because of this, lead screws tend to be less accurate and less efficient than ball screws.

The main advantage of lead screws is that they are simpler and less expensive to manufacture. They are commonly used in applications where precision is less critical, such as in 3D printers and other low-cost CNC machines.

What Are Ball Screws Used For?

Ball Screw Usage and Applications

Ball screws are used in a wide variety of industrial and high-tech applications. Some common examples include:

- Machine tools: Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other CNC machines.

- Robotics: Ball screws are used in many robotic applications, including robotic arms and legs.

- Aerospace systems: Ball screws are used in aircraft control systems and other aerospace applications.

- Medical equipment: Ball screws are used in many medical devices, including surgical robots and imaging systems.

- Automotive industry: Ball screws are used in automotive manufacturing, including assembly lines and robotic welding systems.

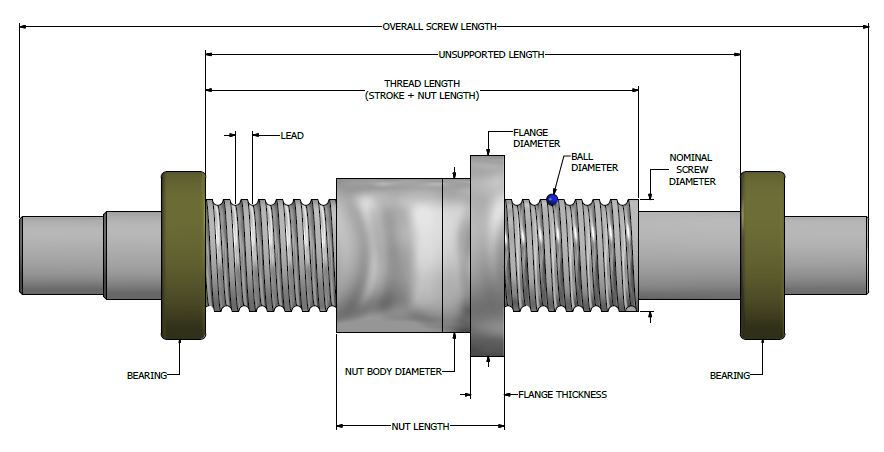

The Elements of a Ball Screw

A ball screw is composed of several elements, including:

- Threaded shaft: The threaded shaft is the core component of the ball screw. It is made of high-strength steel and has a precise thread profile that the ball bearings move along.

- Nut: The nut is the housing for the ball bearings. It is typically made of steel and is designed to minimize friction between the ball bearings and the threaded shaft.

- Ball bearings: The ball bearings are what enable the nut to move along the threaded shaft. They are typically made of steel or ceramic and are designed to minimize friction and wear.

- End supports: The end supports are used to hold the ball screw in place and support the load. They are typically made of cast iron or steel and are designed to minimize deflection and vibration.

Repair and Refurbishment

Over time, ball screws can wear out or become damaged, which can result in decreased accuracy and efficiency. Fortunately, ball screws can often be repaired or refurbished to restore their performance.

Repairing a ball screw typically involves replacing damaged or worn components, such as the ball bearings or the nut. Refurbishing a ball screw involves disassembling the unit, cleaning all of the components, and replacing any worn or damaged parts. The ball screw is then reassembled, lubricated, and tested to ensure that it meets the required specifications.