Overview

Where are Steelflex Covers Used?

Do you have large open pits or exposed machine ways?

If your machine has open machine or inspection pits, walk-on Steelflex covers create a continuous, protective, and walkable surface that makes maintenance easy.

Way Cover Applications

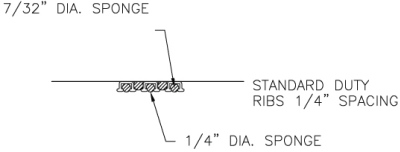

Steelflex Medium-Duty way covers provide way protection against moderate hot chip and coolant loads in milling and drilling machines. With low deflection over wide spans, they are an upgrade over fabric shade protection. All widths can be rolled compactly over a spring-loaded roller. A stainless steel top surface with 1/4″ x 1/4″ aluminum extrusions bonded to the underside provides extra strength and support.

Applications/Environments:

- Moderate hot chip or coolant loads

- Higher ambient operating temperatures

- Machine way protection

- Milling/drilling machines

Standard-Duty Profile & Rib Spacing

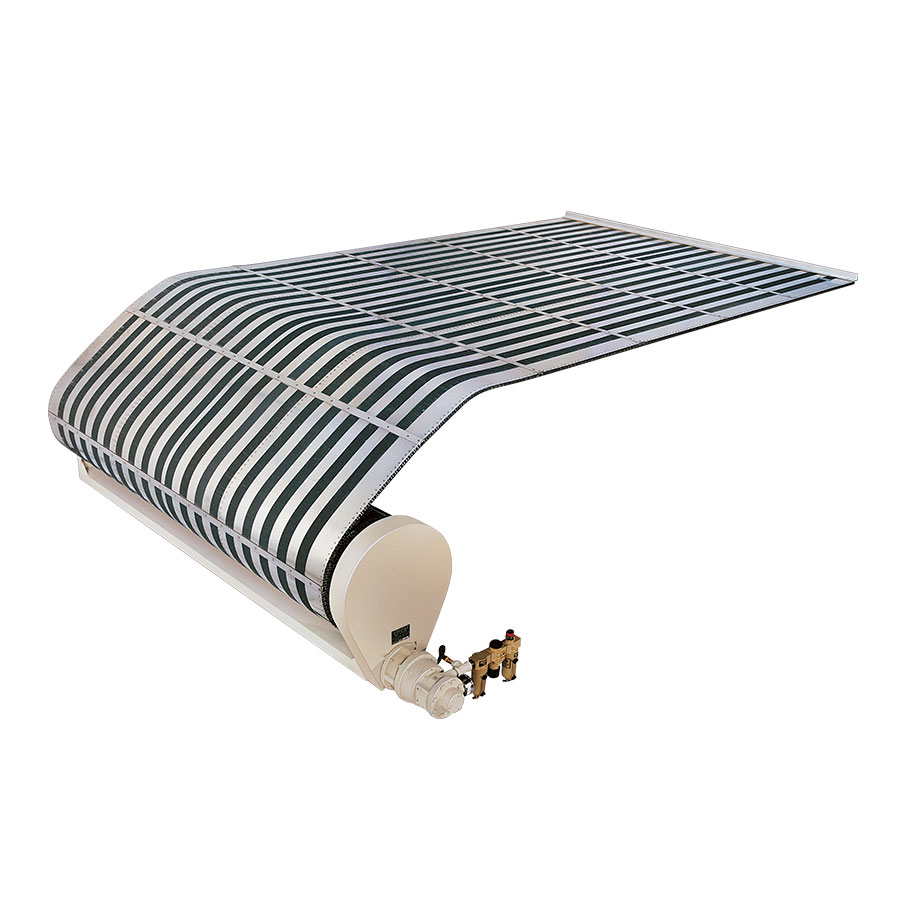

Heavy Duty and Walk-On Applications

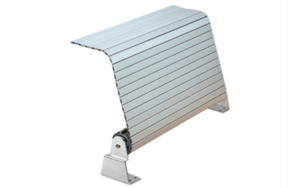

Steelflex Heavy-Duty/Walk-On covers are ideal for protecting machine ways and ball screws from heavy chip loads and dropped tools. They also address the problem of unprotected openings that create a fall hazard for workers. The walk-on surface provides easy machine access during maintenance periods.

Features/Benefits:

- Heavy-duty construction

- Custom-designed to fit your machine or pit

- Safe and strong continuous stainless steel surface

- Impervious to hot chips, coolants and abrasives

- Damaged segments can be individually replaced

Steelflex walk-on covers are ideal for applications where:

- Exposed ways or pits create a safety-hazard for workers

- Containment of large tanks requires a wide/long span

- Workers may need a walk-on surface to access machinery during maintenance periods

Applications/Environments:

- Machine ways or pit cover

- Inspection pit cover or machine tool changer pit cover

- Roll up cover for chemical tanks

Take-Up/Drive Methods:

- Air motor with brake

- Spring drive

- Electric motor

- Manual operation with scroll take-up

Steelflex Walk-On Cover Options:

- Spring Drive Take-Up

- Motor-Driven Scroll Take-Up

- Filter Lubricator Regulator

- Air Brake

- Nylon Riders

- Brush Wiper

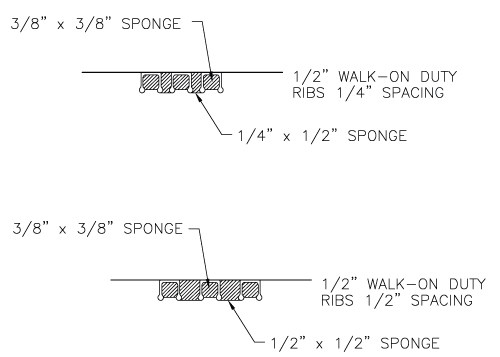

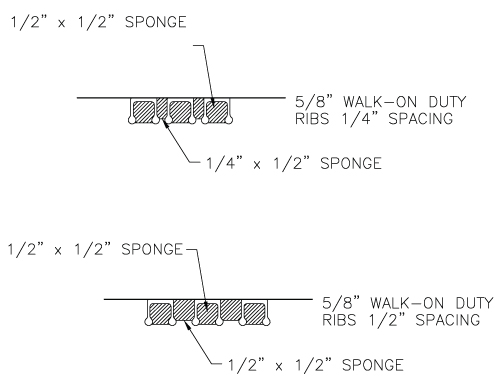

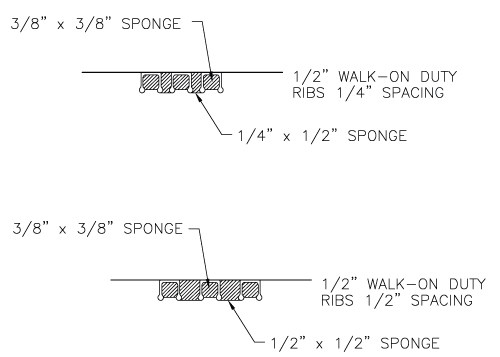

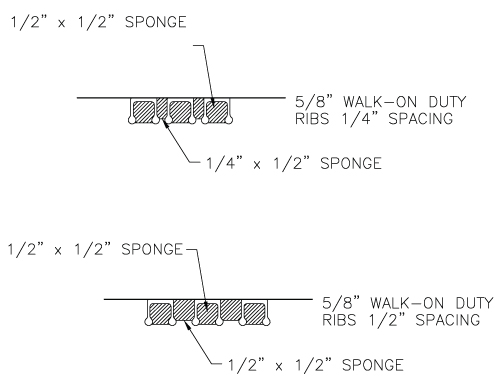

- Sponge Sealed Edges (Sponge sealed edges provided added protection of ball screws and precision scales mounted below the cover by preventing wicking of coolant along the bottom of the cover surface.)

- Non-Skid Paint (left) and Non-Skid Tape (right)

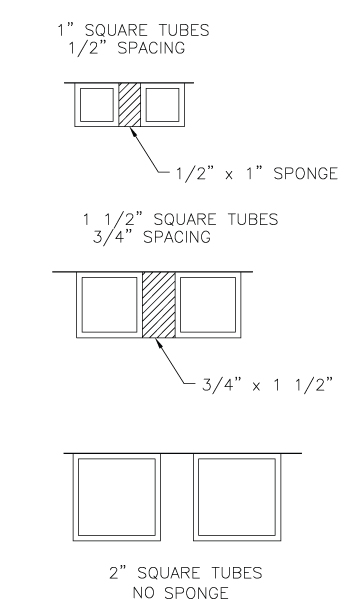

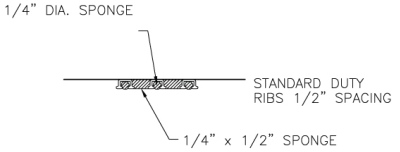

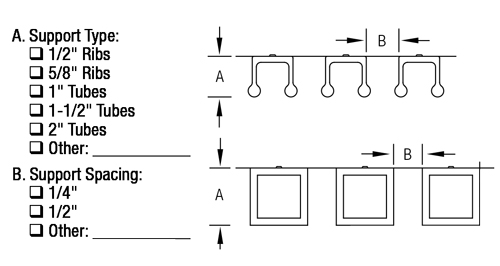

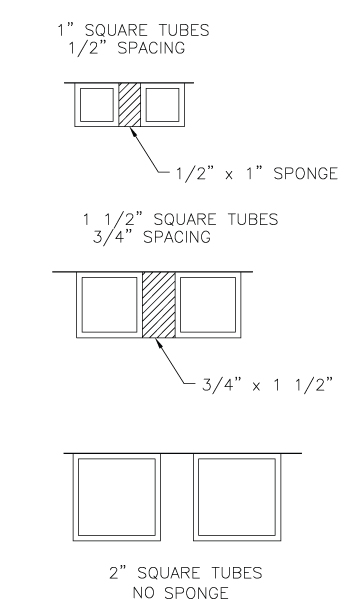

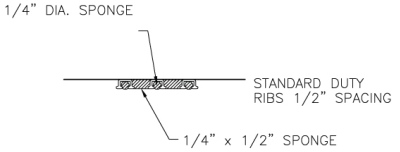

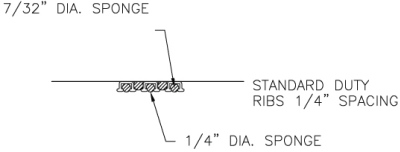

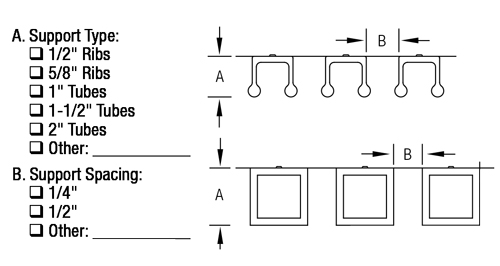

Support rib sizes and spacing – We will recommend support rib/tube size and spacing based on inputs such as weight load and unsupported span. Please view the Steelflex Deflection Calculator Worksheet for more information. For replacement covers, please specify support type and spacing.

1/2” support ribs, shown with optional sponge seal

5/8” support ribs, shown with optional sponge seal

1”-2” square support tubes, shown with optional sponge seal for 1” & 1-1/2” tubes