Dynatect (formerly A&A Manufacturing) delivers engineered motion and protection solutions for machines with deep application knowledge, diverse product offering, and a customer-responsive sales philosophy. Dynatect provides engineering and manufacturing for custom applications that improve human-machine safety and machine uptime. We continue to build our customer experience by improving service differentiation, expanding our product portfolio, and reducing lead times.

DYNAMIC PROTECTION = DYNATECT

The name comes from the words ‘dynamic’ and ‘protection’ because it is the accumulation of over 75 years of experience producing flexible protection for equipment in motion.

Why Choose Dynatect?

- A broad network of 50+ local factory-trained representatives offers onsite support, technical advice, and recommendations

- Speak directly to application specialists to receive upfront design assistance

- Fast delivery of customized products, from concept to application

- We will design and manufacture a turnkey engineered assembly (and one-time projects are not a problem!)

- Access to new solutions for your industry, thanks to our active product research and development programs

- Access to a broad range of materials including metal, engineered plastics, elastomers, and over 120 specialty textiles

- Dynatect has the largest portfolio of protective covers and is the only North American manufacturer of both plastic and metallic cable carriers

- We can meet your needs from standard offerings to custom-engineered products configured around your application

- Regular repeat orders? Dynatect has kanban and JIT programs to ensure reliable delivery with minimal inventory

Our commitment to you: Listen and deliver a practical and cost-effective solution

As you browse our products, consider these designs a mere starting point, as we’re always ready to innovate. We will customize your design whether you need just one piece or thousands. Our engineers and application specialists are keen listeners who understand that knowing the details of your situation are key to producing the perfect solution. We can draw from over 500,000 customized solutions to offer you the widest range of flexibility, backed by a unique blend of design ingenuity and support from concept through application.

Globally, Dynatect has over 75 different manufacturing capabilities to produce the exact right product in the most efficient way. Consider what any of these capabilities can do to help achieve application success!

Elastomer Processing (mixing/compounding of specialty rubber formulations, fabric coating, cold feed extrusion)

Elastomer Molding (injection, compression, transfer, spin-cast, dip, insert, open pour, reaction injection, dual-durometer, flange, hose)

3D Printing (multi-jet fusion, fused deposition modeling)

Metal Cutting (saw, shear, punch, plasma (manual), waterjet, laser)

Elastomer/Plastic/Fabric cutting capabilities (manual cutting/sawing, CNC blade cutting, waterjet cutting, hot blade cutting, CNC router)

Precision Machining capabilities (horizontal, vertical, turning)

Precision Manipulation capabilities (forming/bending, punching, drilling, CNC router, thread cutting/grinding, deburring, whirling, spring winding, calibration, burn-in)

Metal Welding (MIG, TIG, spot-weld)

Thermoplastics Welding (UF/high frequency, thermal, impulse, hot air, hot wedge)

Heat Processing (oven, autoclave, press vulcanizing)

Major Assembly (pleating, shaping, sewing, adhesive bonding, crimping, metal staking, folding, riveting, elastomer heat sealing, automation assisted)

Finishing (tumbling, sandblasting, metal graining, buffing, wet painting, automotive-grade painting)

Major Testing (cycle – multi-axis, electrical, thermal, chemical, pressure, vacuum, air/water tightness, outdoor, 200’ travel)

Repair/Refurbishment (metal way cover, rollup cover, ball screws) Learn more >

Locations and Product Divisions

New Berlin, Wisconsin, USA

Manufacturing, Engineering, Customer Service

Global Headquarters

2300 S. Calhoun Road

New Berlin, WI 53151

ISO 9001:2015 Certificate (PDF) • Map It

Valparaiso, Indiana, USA

Manufacturing & Engineering

Gortrac® cable carriers and Gortite roll-up doors

ISO 9001:2015 Certificate (PDF) • Map It

Traverse City, Michigan, USA

Manufacturing & Engineering

Dynatect LSI: ball screw products, ball screw repair

ISO 9001_2015 Dynatect-LSI • Map It

New Berlin, Wisconsin, USA

2425 S. 162nd Street

New Berlin, WI 53151

Tracy, California, USA

Manufacturing & Engineering

Dynatect Ro-Lab, molded rubber, urethane, and plastics

Map It

Kolbermoor, Germany

Dynatect Europe

Rosenheimer str. 64a

Kolbermoor

D-83059 Germany

Map It

Go to Local Website

León, Mexico

Gortite® Delivery Vehicle Roll-Up Doors and Handles

Blvd. Industrial El Saucillo No. 102, Col.

Parque Sur Industrial Leon El Saucillo

Leon, Gto. Mexico

Map It

Wuxi, China

Zijing Rd No. 43 Hudai Industrial Park

Bin Hu District, Wuxi 214161

Jiangsu Province, China

Go to Local Website

Industries Served

Dynatect’s broad portfolio and global footprint serves a vast array of industries with inquiries on new applications every day!

General Industrial:

- Machine Tool: Cutting machines, lathe and turning machines, grinding machines, CNC or non-CNC controlled, and more

- Industrial Users: Industrial chemical processing, metal processing (including extrusion, plating), plastics processing, and more

Harsh In-Field Environment:

- Aerial Work Platforms (AWP): Self-propelled telescoping boom lifts

- Aerospace/Defense: Space exploration, launch infrastructure, airplanes, government/military, satellite communications, and more

- Bucket Trucks: Vehicle mounted aerial lifts including bucket trucks, digger derricks, telehandlers, vertical mast, and more

- Construction: General & road construction, horizontal directional drilling (HDD), boring, concrete/gypsum handling, and more

- Mining & Energy: Mining trucks/equipment, earthmoving equipment, electricity generation/distribution, and more

- Oil & Gas: Petroleum, oil, natural gas (including meters and LNG), oilrigs/drilling, fracking, dewatering, and more

Transportation:

- Delivery Vehicles: Last mile delivery vehicles, vehicle OEMs, upfitters, vans, step-vans, trucks, parcel delivery, autonomous delivery vehicles, and more

- Fire & Emergency: Fire trucks, airport emergency vehicles, wrecker vehicles, logistical vehicles, tactical military vehicles, and more

- Train & Ground: Buses (including standard, articulated, coach), freight train bilevel box car, passenger train/rail, monorail, and more

- Work Truck: Utility trucks, utility trailers, tanker trucks, lawn care trucks, and more

Robotics & Automation:

- Material Handling: Conveyors, cranes, transport, material positioning, lift tables, unit load formation storage, palletizers, and more

- Motion Control: Linear motion systems, packaging/converting, bottle capping, industrial printing machines, and more

- Robotic Systems: Robots, automated processing, 3D printing, pick & place, safety doors for manufacturing cells, and more

Additional Industries:

- Agriculture: Farm-related (including spreaders and harvest machines), produce-processing, dairy/milking, forestry, and more

- Commercial: Window cleaning wipers, sports equipment, metrology, food & beverage, entertainment, academic, and more

- Medical: Diagnostics (including MRI, CT, mammography), incubators, blood centrifuge, catheters, surgical beds, and more

How it All Started

Over seventy-five years ago, when founder Gerald “Doc” O’Rourke saw that neighborhood kids needed footballs and basketballs, he started a basement operation to provide them. After introducing a line of sewn leather industrial bellows, Dynatect (formerly A&A) began designing and manufacturing components used in virtually all types of equipment and machinery, becoming a single-source provider for machine protection, cable/hose management, and compartment roll-up doors. (Slip clutches, ball screws, and molded products were added in the last decade).

Today, Dynatect is a market leader in industrial equipment protection with eight production facilities and over 600 employees worldwide. Dynatect provides customer proximity all over the world thanks to its subsidiaries in Europe and Asia.

- 1945: Gerald O’Rourke founds A&A Manufacturing in Milwaukee, Wisconsin. Initial offerings include sewn fabric footballs and basketballs in response to a lack of youth athletic equipment by manufacturers who were previously redeployed to wartime production. Company founder uses his initials “GOR” as prefix-branding on many products including the subsequent umbrella brands of Gortite and Gortrac. (Since 2014, the company’s contemporary name is “Dynatect”)

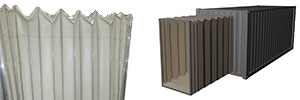

- 1949: Dynatect shifts focus to producing flexible fabric bellows providing dynamic protection for industrial applications including machine tools. Over the following 20 years, Dynatect adds fabric roll ups covers and metal roll up covers. These offerings and others evolve into today’s highly recognized line of dependable Gortite protective bellows and covers.

- 1964: Custom Products Corporation (CPC) is founded in Connecticut, manufacturing slip clutches under the brand Polyclutch.

- 1967: Dynatect adds telescopic metal cover and wiper capabilities for machine tools under the Gortite brand. Subsequently adopted by the largest US OEMs as industry standard.

- 1970: Stabiflex is founded in Indiana, manufacturing steel cable & hose carriers.

- 1973: Dynatect adds XY face shield (multi-axis face-shield) capabilities. Over the next decade, Dynatect also develops aluminum slatted metal roll up doors for machines under the brand Alumaflex.

- 1973: Leveraging industrial sewing and metalwork capabilities, Dynatect adds articulated bus passageway bellows capabilities for the transportation market. Subsequently expands applications to trains and monorails.

- 1976: Ro-Lab American Rubber (Ro-Lab) is founded in Tracy, California. Ro-Lab provides custom molding specializing in engineered polymers. This evolves into molded bellows, bus bumpers, and athletic pitching wheels.

- 1982: Taking advantage of exposure to the machine tool market, Dynatect acquires Stabiflex, founded in 1970. Cable carrier offerings are promoted under the Gortrac product line.

- 1985: Lead Screws International (LSI) is founded in Traverse City, MI. LSI evolves to design, manufacture, and repair precision ground ball screws for the machine tool industry.

- 1992: Milwaukee Protective Covers (MPC) is founded, manufacturing roll up covers and RF thermically welded bellows (heat sealed bellows).

- 1998: Dynatect opens a new 75,000 square foot manufacturing facility for cable carriers in Valparaiso, IN. Production includes plastic cable carriers.

- 2000: Utilizing aluminum slatted roll up cover capability, Dynatect develops aluminum slatted roll-up doors (RUD) for fire and emergency vehicles. This includes establishing an automotive-grade paint line. Dynatect RUD is subsequently adopted by the largest fire truck OEM as the default offering. Applications expand to include work trucks and military vehicles.

- 2002: Capitalizing on machine tool exposure, Dynatect acquires Milwaukee Protective Covers, established in 1992.

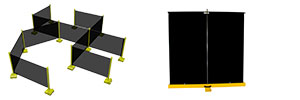

- 2007: Tapping into general industrial exposure, Dynatect adds portable and modular weld curtains capabilities.

- 2007: Thodacon Machine Tool Accessories is founded in China, manufacturing way wipers, telescopic covers, bellows, aluminum slatted aprons, roll up covers, and pit covers. Subsequently services Europe, Asia, and North America.

- 2008: Leveraging general industrial exposure, Dynatect acquires Custom Products Corporation, founded in 1964.

- 2008: Utilizing experience with metal cable carrier for Aerial Work Platforms (AWP) in construction, Dynatect introduces Gortrac SX series AWP metal cable carrier for longer-reach applications featuring fewer components, lighter weight, and lower cost. Subsequently adopted by the largest AWP OEMs as global industry standard.

- 2011: Drawing upon global demand for metal cable carrier by multi-national construction OEMs, Dynatect establishes importer presence in China.

- 2012: Leveraging experience in transportation and construction, Dynatect acquires Ro-Lab, established in 1976.

- 2012: Tapping into increasing global exposure in machine tool, Dynatect acquires Halltech GmbH a machine tool distributor in Germany servicing Europe.

- 2013: Leveraging exposure to machine tool market, Dynatect acquires Lead Screws International, Inc (LSI), established in 1985.

- 2013: Taking advantage of distribution in Europe, machine tool protection, and transportation protection, Dynatect acquires MFB Technik Schillig GmbH (MFB). MFB manufactures machine tool and transportation protection products in Germany for Europe. Dip-molded bellows were added to the portfolio.

- 2013: Thodacon Werkzeugmaschinenschutz GmbH (Thodacon GmbH) is founded in Kolbermoor, Germany as the sales office of Thodacon Wuxi to service the European machine tool market.

- 2014: With a portfolio that changes and expands over 70 years, now focused on DYNAmic proTECTion, company rebrands under one unified trade name and brand mark: “Dynatect”.

- 2014: Drawing upon construction market and custom molding experience, Dynatect adds capability to manufacture pipe guides and rod wipers for horizontal directional drilling equipment.

- 2015: Employing large format fabric manufacturing like bus bellows, Dynatect adds capability to manufacture large format machine roof covers to service both machine tool and robotics & automation markets.

- 2015: Steinbock GmbH is founded in Germany as a distributor for machine tool accessories including ecommerce. Thodacon GmbH acquires Steinbock in 2018.

- 2016: Leveraging transportation passageway bellows, Dynatect adds capability to manufacture mobile building bellows for connecting cargo containers which are retrofit into hospitals/offices.

- 2017: Applying decades of roll-up machine door experience and automation, Dynatect adds capability to manufacture high-speed automated machine safety doors for work cells to service robotics & automation market.

- 2018: Tapping into robotics & automation and cable carrier experience, Dynatect adds two additional long travel cable carrier solutions ideal for 7th axis robots and other applications.

- 2018: Revisiting the company’s beginning with athletic equipment, and further diversifying, Dynatect adds capability to manufacture dual-durometer urethane spin-cast pitching wheels for pitching simulators. Subsequently adopted by the largest US athletic pitching simulator OEMs as industry standard.

- 2019: Dynatect acquires Thodacon Machine Tool Accessories in China (established 2007) and Thodacon GmbH in Germany (established 2013). All Dynatect European entities enter 2-year journey to consolidate sales and manufacturing organization/operations becoming Dynatect Europe.

- 2020: Leveraging US manufacturing of cable carrier, Dynatect establishes stamping and assembly of Gortrac cable carrier in China for Asia AWP industry. Subsequently adopted by the largest China AWP OEMs as industry standard.

- 2020: Applying robotics & automation market experience, adds capability to manufacture high-speed metal roll up doors for robotic laser welding work cells.

- 2021: Employing transportation roll up door and automotive paint capabilities, Dynatect adds capability to manufacture delivery vehicle roll up doors for last mile delivery vehicles and work trucks.

- 2023: In response to increasing OEM demand for vehicle roll up doors and door handles, Dynatect opens an 85,000 square foot manufacturing facility in Leon, Mexico.