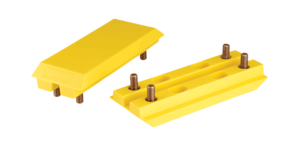

Urethane Molding Processes

Urethane Compression Molding: Liquid polyurethane is poured into a mold and cured in a compression press with capacities up to 250 tons. This technique is most suitable for components that must maintain dimensional accuracy and repeatability.

Benefits:

- Dimensional precision and repeatability

- Capable of being very flexible or very rigid

- Very durable and wear-resistant

Urethane Low Pressure Injection Molding: Injection of liquid polyurethane into a closed mold under low pressure, in a process ideal for projects in which a component size, component shape or tooling configuration would make compression molding impractical.

Benefits:

- Ideal for unusual sizes or shapes

- High precision and intricate parts

- Finish is minimized

Open Cast Urethane Molding: The pouring of liquid polyurethane into an open mold, which is then cured in an oven or on a heated table. Usable on part sizes from less than an ounce to more than 500 lbs. Excellent for projects where conventional tooling would be expensive or impractical.

Benefits:

- An economical alternative to conventional tooling

- Low cost tooling: a mold capable of handling high pressure is not required, soft tooling may be made out of urethane or silicone

- Suitable for smaller production runs

- High performance product

RIM (Reaction Injection Molding): Reaction Injection Molding is the injection of polyols and isocyanates into a closed mold, triggering a chemical reaction that causes the material to expand and form the finished product.

Benefits:

- Effective in forming extremely large products with very light weights

- Able to improve or eliminate secondary operations

- Eliminates sink marks

- Workable for flexible or rigid products in foams or solids

- Delivers reliable control of components with varying wall thicknesses

Polyurethane 101

What is cast polyurethane? Cast polyurethane is a polymeric material created by a combination of polyols and diisocyanates that, when extended by various curatives, produces materials with a dynamic array of properties tailored to a wide range of applications.

Polyurethane materials offer a dynamic array of properties which can be tailored to a very wide range of applications. They are a great alternative choice to plastics, traditional rubber and metals because they embody characteristics of each. Cast polyurethane can be produced to resist chemicals, water, impact, shearing, tearing and wide range of temperatures or other hazards which can cause failure in other materials.

Tensile & Tear Strength – In general, polyurethanes have a high tensile (tension) and tear strength compared to other elastomers which makes polyurethane more resilient in harsher elements and more abrasive work conditions.

| Advantages |

Resistances |

| Lightweight |

Abrasion |

| Noise Reduction |

Impact |

| Hardness Flexibility |

Shearing/Tearing |

| Cost Efficient |

Atmospheric (Oxygen/Ozone/UV) |

| Metal Bonding |

Temperature |

| Machinability |

Water |

| Varied Coefficient of Friction |

Chemicals |

| High Tensile & Tear Strength |

Corrosion |

Polyurethane Advantages

Consider Polyurethane over plastic, metal or rubber, to improve your design.

Polyurethane is a surprisingly versatile material that can bring a solution to your most challenging design applications. It offers load bearing capabilities, abrasion resistance and impact absorption in a single material, which may be preferable compared to using plastic, metal or rubber (see below). In many instances, it can produce significant cost savings by eliminating coating or painting, expensive tooling or machining operations. Some tooling is required, but is often much easier to produce than the tooling required for the other materials.

Polyurethane Advantages over Plastic:

- Lower Tooling Costs

- Faster and Better Prototype Accuracy

- Higher Wear Resistance

- Higher Durability

Polyurethane Advantages over Metal:

- More Cost Effective

- Lighter in Weight

- Faster Lead Time

- Elevated Corrosion Resistance

Polyurethane Advantages over Rubber:

- More Cost-Effective

- Low-pressure Tooling

- Higher Load-Bearing Capacity

- Higher Wear Resistance

Compare Properties

| Property |

Polyurethane |

Nitrile Rubber |

Neoprene Rubber |

Natural Rubber |

SBR |

Butyl |

| Tensile Strength (MPa) |

20.7 to 65.5 |

13.8+/- |

20.7+/- |

20.7+/- |

18.8+/- |

18.8+/- |

| Durometer |

5A to 85D |

40 to 95A |

40 to 95A |

30 to 90A |

40 to 90A |

40 to 75A |

| Specific Gravity |

1.10 to 1.24 |

1.0 |

1.23 |

0.93 |

0.94 |

0.92 |

| Tear Resistance |

Outstanding |

Fair |

Good |

Good |

Fair |

Good |

| Abrasion Resistance |

Outstanding |

Good |

Excellent |

Excellent |

Good-Excellent |

Good |

| Compression Set |

Good |

Good |

Fair-Good |

Good |

Good |

Fair |

| Rebound |

Very High to Very Low |

Medium |

High |

Very High |

Medium |

Very Low |

| Gas Permeability |

Fair-Good |

Fair |

Low |

Fair |

Fair |

Very Low |

| Acid Resistance |

Fair-Good |

Good |

Excellent |

Fair-Good |

Fair-Good |

Excellent |

| Aliphatic Hydrocarbons |

Excellent |

Excellent |

Good |

Poor |

Poor |

Poor |

| Aromatic Hydrocarbons |

Fair-Good |

Good |

Fair |

Poor |

Poor |

Poor |

| Oil and Gas Resistance |

Excellent |

Excellent |

Good |

Poor |

Poor |

Poor |

| Oxidation Resistance |

Outstanding |

Good |

Excellent |

Good |

Good |

Excellent |

| Ozone Resistance |

Outstanding |

Fair |

Excellent |

Fair |

Fair |

Excellent |

| Low Temperature Resistance |

Excellent |

Good |

Good |

Excellent |

Excellent |

Good |

Durometer (Hardness) Scales: