Material Handling & Packaging

Dynatect provides custom-engineered solutions for the material handling and packaging industry. By working with industry leaders, Dynatect has gained an understanding of the industry’s unique challenges and demands in order to develop innovative products and solutions to enhance safety and performance. Dynatect’s fundamental goal is to be your trusted partner and help you gain a competitive advantage.

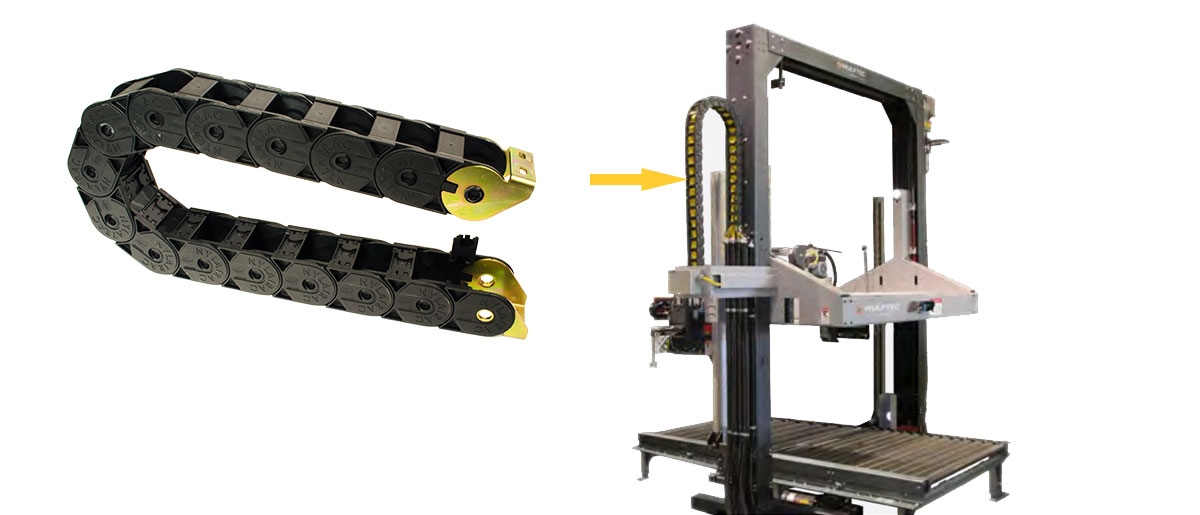

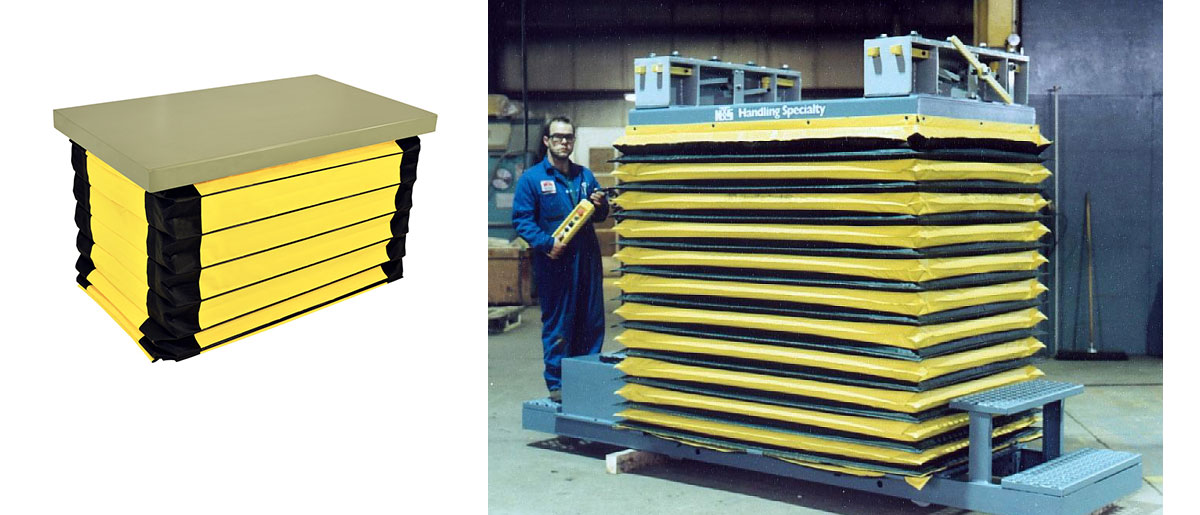

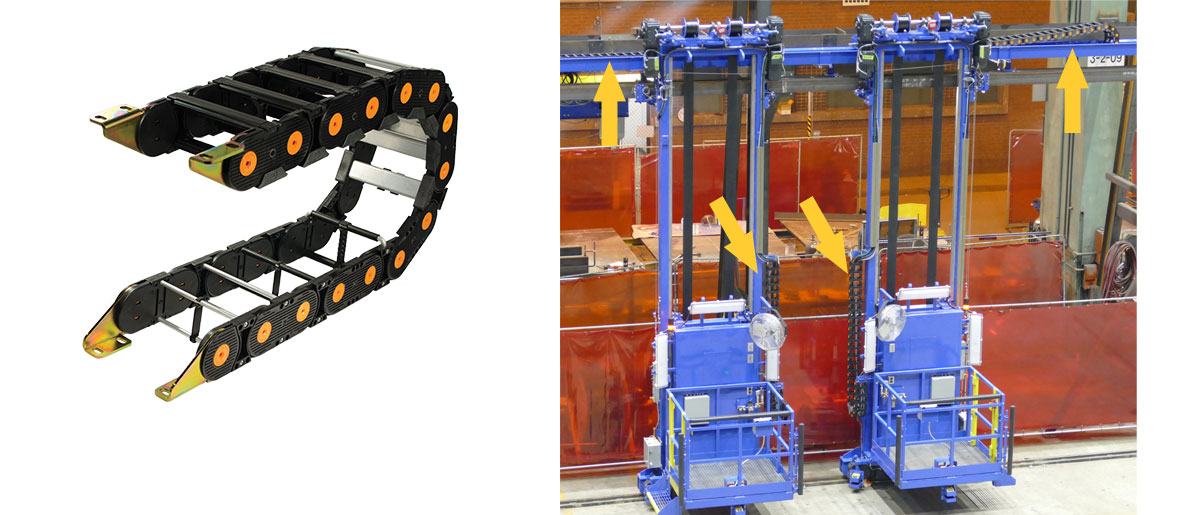

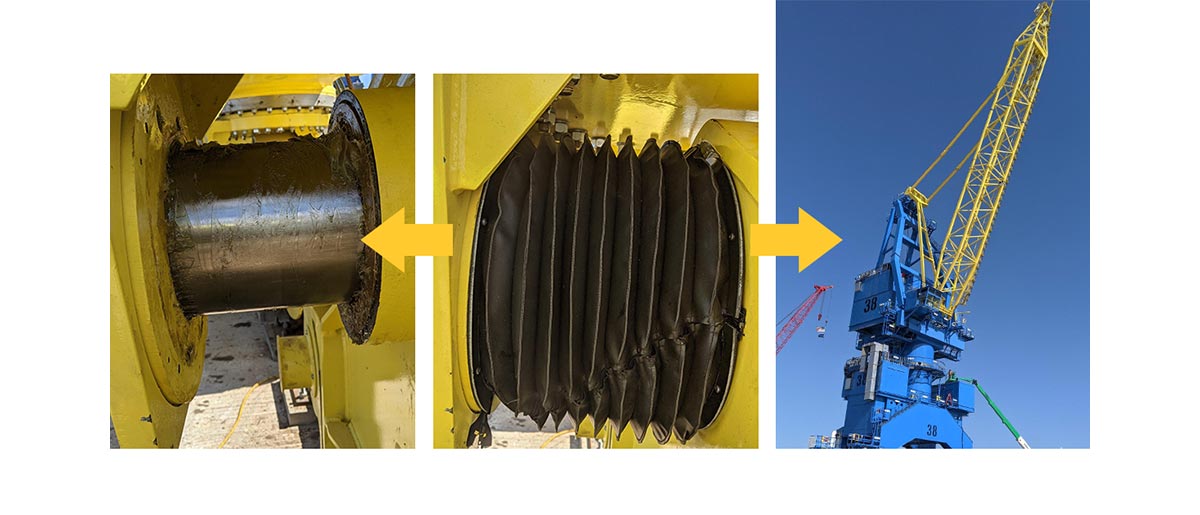

Winning solutions for this industry draw from our line of protective covers and bellows, cable carriers, slip clutches, safety barriers, and automated roll-up doors. These work together to mitigate damage and downtime for equipment in motion.

End of Line Palletizing Systems

Are you designing end-of-line palletizing systems while anticipating more global harmonization of safety codes? Pallet wrapping machines benefit from guarding that permits intermittent access while separating workers and moving machinery with a physical barrier. Maintain productivity and safety with Dynatect’s Automated Machine Safety Doors!

Material Handling and Packaging Considerations

- Safety Requirements for Industrial Robots, Robot Systems, & Integration (ISO 10218-1, ISO 10218-2)

- Risk/Safety Performance Levels and Compliance (Ple/Cat-4, SILCL3 per EN62061 and EN/ISO 3849, ANSI B11.19 1990 E4.2.3.3.5, ISO 13849-1 Safety-Related Parts of Control System – SRP/CS)

- Pinch Points (US OSHA standard number 1910.219)

- Functionality (acceleration, speed, long travel, loading, watertight, aesthetics, ergonomics)

- Personnel Hazard Protection (containing the manufacturing process):

- Mechanical (noise, vibration, obstacle detection, physical separation, overload protection)

- Electrical & Electrostatic (accidental discharge)

- Maximizing Uptime (reduce impact from incidental operator interference entering dangerous work stations or cross traffic)

- Safety Distances (ISO 13857 – preventing any breach in a machinery hazard zone for both lower and upper limbs)

- Positioning of Safeguards and Barriers (ISO 13855 – minimum safe distances relative to approach speeds)

How Can We Help?

Use our contact page to get in touch with us directly for placing an order, requesting a quote, or getting your products repaired.

Use Our Contact Form