Aerospace and Defense

Dynatect has an industry-leading reputation for engineering and manufacturing unprecedented dynamic solutions that work for the first time. Solutions like these are critical in “cannot fail” applications, including aerospace, launch infrastructure, radar and satellite communications, military hospitals, bomb-diffusing robots, and more. Dynatect makes solutions that meet extreme conditions including tallest, longest, fastest, coldest, hottest, outdoor, pressurized, and chemical exposure. Dynatect also has over 75 different manufacturing capabilities to use the right construction method with the right materials to make your unique application successful.

Applications

-

Defense Dynamic Protection

Some military aircraft (not shown) include radar/antennae using Dynatect solutions for mechanical overload protection and cable management. Dynatect Polyclutch mechanical slip clutches uniquely provide for intermittent, continuous, or overload torque control up to 1000 lb-in and low backlash. Dynatect’s SP series plastic cable carriers are ideal for high-speed applications and feature maximum accessibility with hinged bars that can open on the inner or outer radius. Dynatect’s folded bellows provides a sealed/dust-proof wiring conduit and balances flexibility with durability. To minimize buildup of electrical charge, the bellows also include a conductive layer of material that provides an anti-static environment.

-

Rocket Launch Protection

The rocket launch industry is rapidly expanding, targeting Low Earth Orbit (LEO), Near Earth Orbit (NEO), and Deep Space transportation/logistics. These industry leaders come to Dynatect for unprecedented, harsh-environment, mission-critical dynamic protection products. Launchpad positioning and service tower detachment have a wide variety of cables and hoses that need to be managed while in motion. Dynatect Gortrac metal cable carriers have been highly engineered to accommodate those very large and complicated configurations in harsh conditions to ensure predictable, repeatable performance. Dynatect Steelflex roll up covers have also been highly engineered and automated to cover critical components from debris associated with both launch and storage.

-

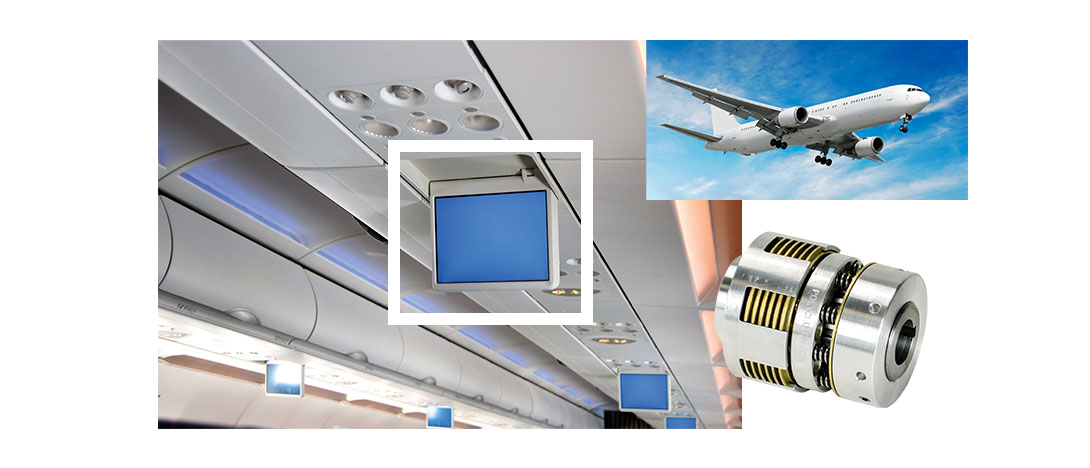

Commercial Aircraft Screen Clutches

Some aircraft, trains, and buses use motorized screens which pivot down for passenger education and entertainment. These screens can be subject to interference, notably passengers bumping or moving them. To protect the motors and gears from overload or damage, these applications use Dynatect’s slip clutches.

-

Aerospace Roll Up Doors

In the tight spaces of aircraft, swing-out doors are a hazard. These applications use Dynatect’s roll up doors which are fully contained inside the cabinet and feature a secure latching mechanism. These doors also feature a spring-loaded roller that is easy to open, close, and even remain in a partial-open position. Lock options are also available.

-

Missile Silo Bellows

Defense installations sometimes include a heavy-duty cover which open via an automated rod, cylinder, or screw. This application in Fort Greely, Alaska is tested regularly and must remain operable despite UV rays, rain, snow, ice, debris, and -40°F conditions. Other factors excluded the use of silicone-based materials which are typically used for low temperature conditions. Through testing, Dynatect was able to supply the ideal combination of elastomer and the Gortiflex bellows construction to provide sustained functionality and durability.

-

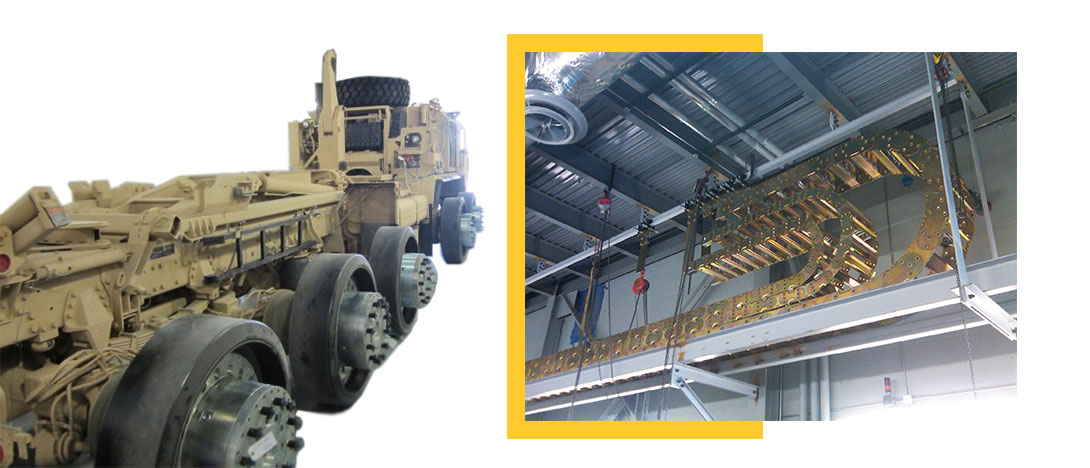

Military Vehicle Metrology Cable Carrier

The US Army developed a dynamometer for measuring the engine output of tanks, Humvees, troop transports, and supply trucks. All the hoses and cables were fed through an overhead gantry and using Dynatect Gortrac XL series steel cable carriers. They were in a nested configuration and designed to self-support without the need for rollers or guide troughs for lateral stability, further reducing cost, complexity, space and installation time. Dynatect provided pre-installation site visits, structural calculations, and installation supervision helping ensure the project completed ahead of deadline.

-

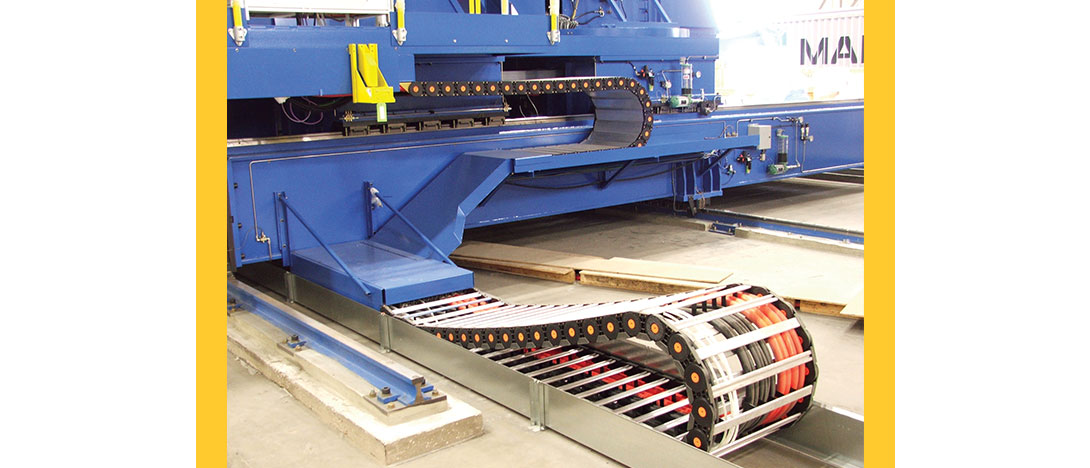

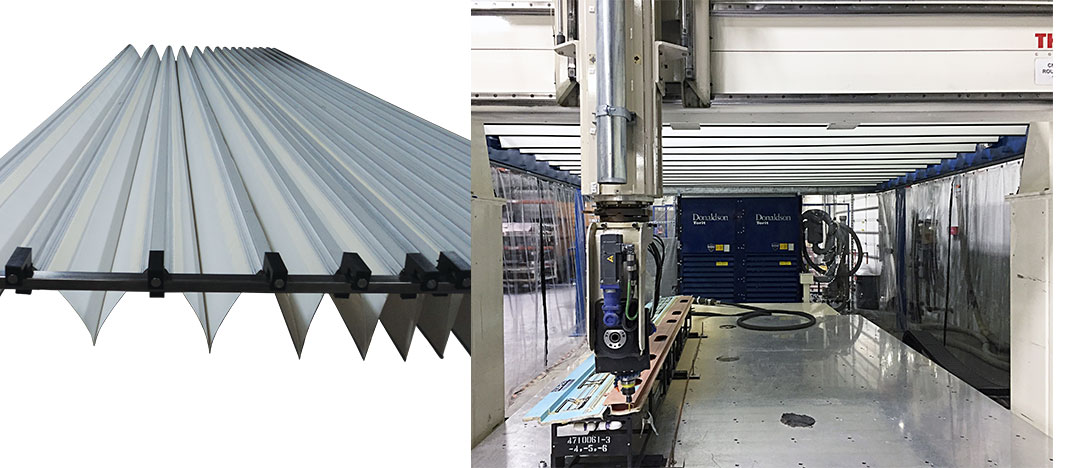

Aerospace Wing Fabrication Cable Carriers

Manufacturing a full-length aircraft wing often includes multi-axis machines that move the entire length of the wing todrill and fill” with fasteners. Dynatect’s Gortrac TL open-style carrier (shown bottom) is equipped with aluminum flat bars and low-friction modular sliders in a lowered mounting height configuration. The enclosed-style carrier (upper) shields cables from ejected rivet heads and debris with heavy-duty bolt-in aluminum armor plates.

-

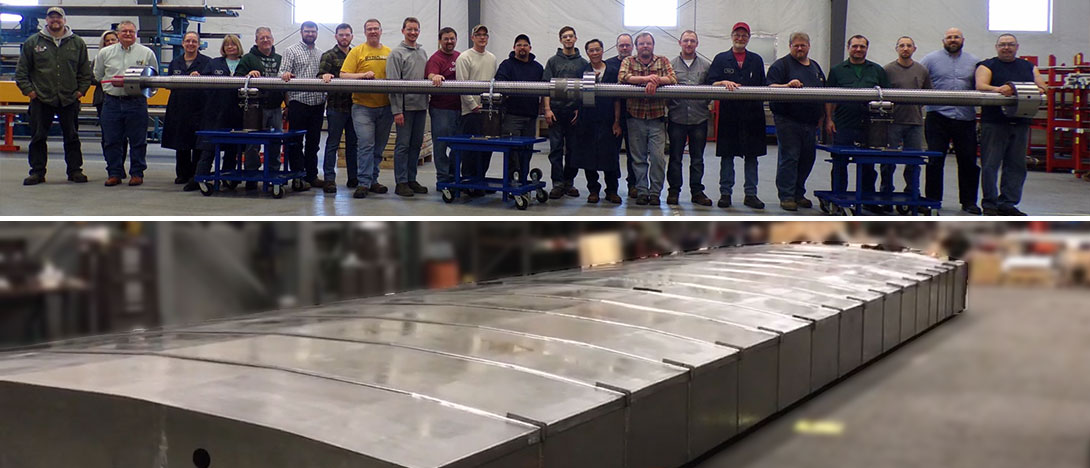

Aerospace Wing Fabrication Ball Screws and Telescopic Covers

Manufacturing a full-length aircraft wing often includes machines that move the entire length of the wing along a track via automation. That automation often uses Dynatect’s LSI precision ground ball screws which provide a lead accuracy of +/-0.0005", diameters up to 6”, and lengths up to 67 feet. The machining and welding can include hot process-generated debris that could fall on that track or ball screw. A steel telescopic cover is used to cover the track and automation to protect the infrastructure from hot debris. Dynatect is known for being able to make unprecedented applications work, including this large cover spanning 18 feet (5.4M) wide and extendable to 64 feet (19.5M)! It weighs over 18,000 lbs (8165 kg) but remains smooth enough to be manually operated in 17 continuous sections!! Checkout this pre-installation video.

-

Aerospace Machine Roof Covers

Air Cleaning Solutions had a 30 foot aerospace machining center that generated dust and debris into the adjoining work areas. The strip curtain wall was insufficient because the process contaminates also went up and over the wall. Dynatect provided a machine roof cover solution with translucent panels allowing light through so the process could still be observed. An additional benefit was noise attenuation. Dynatect’s roof covers feature a low friction gliding system that can travel up to 60 meters/minute and are capable of over 1G acceleration. Checkout this post-installation video.

-

Military Molded Protection

Dynatect makes a wide variety of custom formed rubber components for military/defense applications (not shown). This includes a custom molded silicon rubber pad that is used to store and transport 8” diameter missiles. This also includes a rubber exhaust hose used on naval applications. Dynatect has broad molding capabilities including insert molding, close tolerance molding (including RMA-A1 standard), and combining two elastomers with different hardness into one molded product.

-

Controls and Seating Protection

Aerospace and Defense applications include a wide variety of adjustable seats that create pinch-point or are subject to interference from dropped items. Dynatect consistently provides reliable dynamic protection for these demanding applications. One application is applying VulcaSeal bellows for military aircraft drone stations (not shown). Another application includes Steelflex shade rollers and bellows that dynamically cover gaps between airline seats. Another application is a molded bellows used with a joystick control.

-

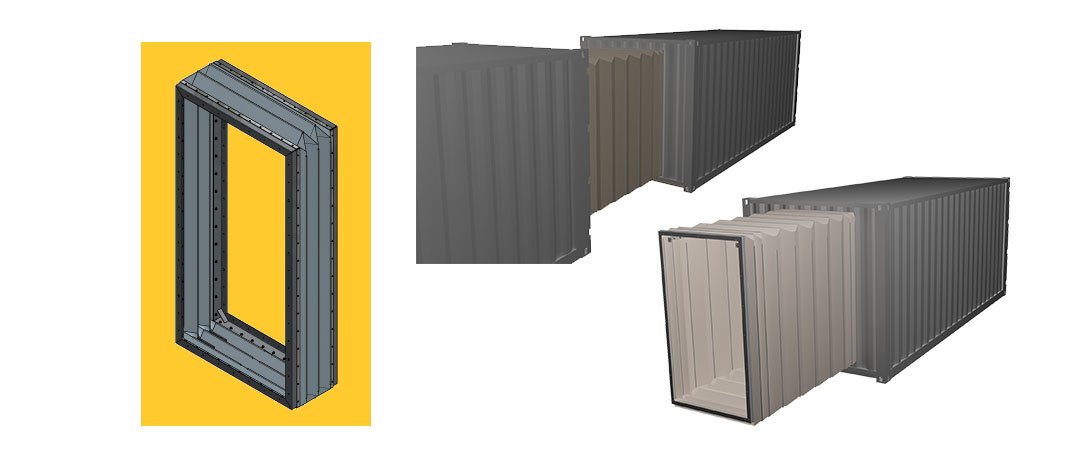

Mobile Hospitals and Command Centers

Military applications often require mobile command centers and hospitals (not shown). These are often made up of specialized modular containers which are connected in the field by passageway bellows. For these applications, Dynatect’s provides large-format bellows which are flexible enough to accommodate field alignment issues, while sturdy enough for the most demanding outdoor applications.

-

Aerospace Metrology Ball Screws

Aircraft testing includes wind tunnels and anechoic chambers – for which positioning needs to be very precise and repeatable. These applications use Dynatect’s LSI precision ground ball screws which provide a lead accuracy of +/-0.0005", minimize backlash, and eliminate deadbands for diameters up to 6” and lengths up to 67 feet.

-

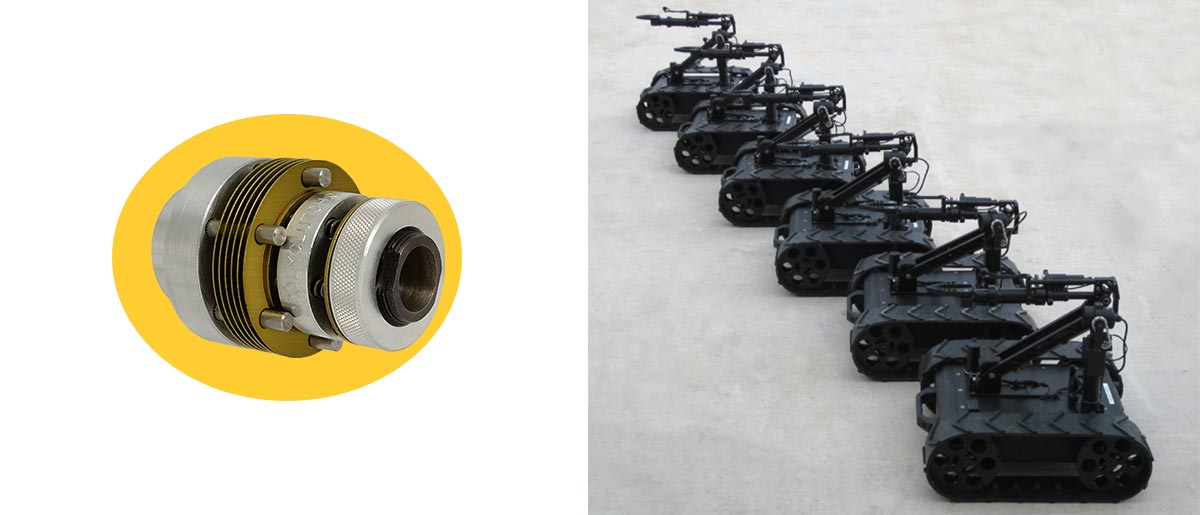

Clutches for Tactical Robotics

Demanding field robotics require overload protection to keep gears from shearing, motors from overloading, and batteries from prematurely draining. These robotic arms use Dynatect’s Polyclutch Slip-Ease clutches which feature low backlash and torque capacities of up to 1000 lb-in. Featured customers of these robotic systems include: Lockheed Martin Missiles and Space, General Dynamics, Applied Minds, Exponent, NASA Goddard Space Flight Center, NASA Glenn Research Center, BAE Systems, Fermi National Accelerator Laboratory, Air Force Research Lab, Tenix Defense, US Army, and the US Navy.

Discover solutions for your industry

How Can We Help?

Use our contact page to get in touch with us directly for placing an order, requesting a quote, or getting your products repaired.

Use Our Contact Form