Steel & Aluminum Processing Industry

Heavy-Duty Solutions for Harsh-Duty Environment

Dynatect has decades of experience providing rugged solutions designed for extreme industrial environments like hot and cold strip mills. Examples where Dynatect products have been used in steel processing include:

- Roughing Stands and Finishing Mills… walk on pit covers

- Coil Transfer Cars… walk on pit covers and metal cable carriers

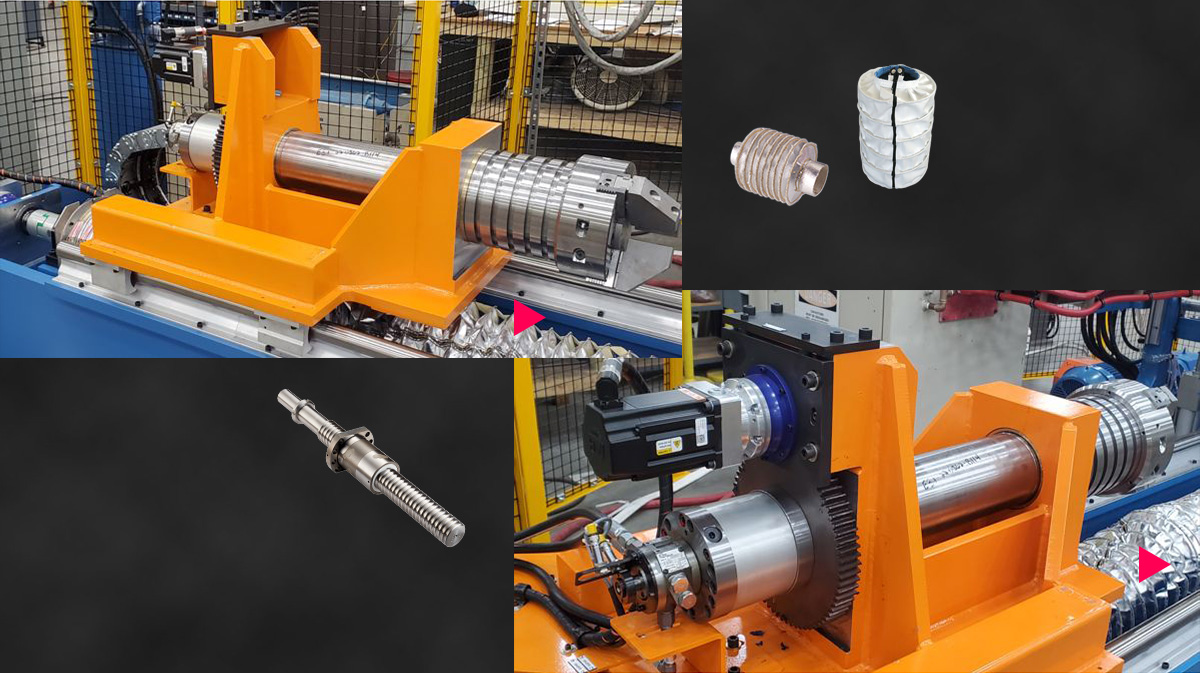

- Roll Grinders… telescopic metal covers, durable fabric way covers, cable carrier, and ball screws

- Scalpers… walk on pit covers, telescopic metal covers

- Vertical Edgers… round spline cover bellows

- Hot Rolled Mills and Plate Mills… cable carriers

- And Many More!

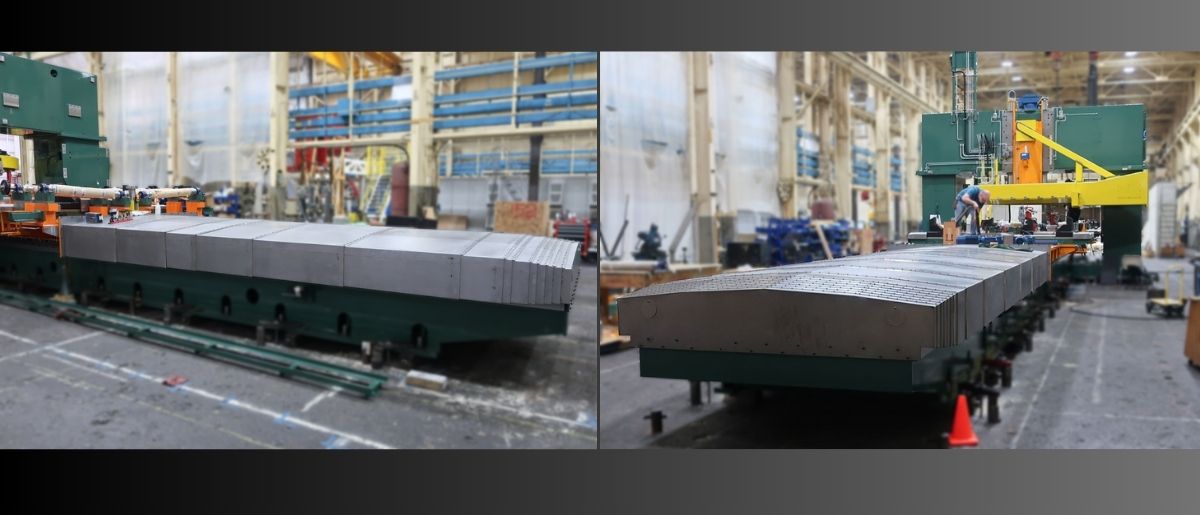

Planer Mill Pit Cover Application

Large machine tools such as planer mills often are installed partially below floor level, resulting in potentially hazardous pits. Workers must remove pit grates or slats to service the machine. Here, metal roll-up, walk-on covers offer an alternative. Typically made of reinforced stainless steel, these covers allow partial pit access while preventing falls at other times or into other pit areas.

Case in point: One aircraft manufacturer uses large fiber placement machines to build fuselages from composites. Adjustable tailstocks of the two-station machine travel on guideways located in a pit below floor level. Production workers must access workpieces as they’re produced, necessitating pit covers during production, yet also requiring a way to remove the covers for repairs and adjustments. Grating is time-consuming to move, and slats require complex support structures that complicate maintenance tasks. Instead, the aircraft manufacturer uses rugged walk-on metal pit covers with extruded aluminum stiffening ribs bonded to stainless steel sheets; there are no hinges to collect debris. These roll up onto steel rollers equipped with take-up mechanisms.

Featured Products

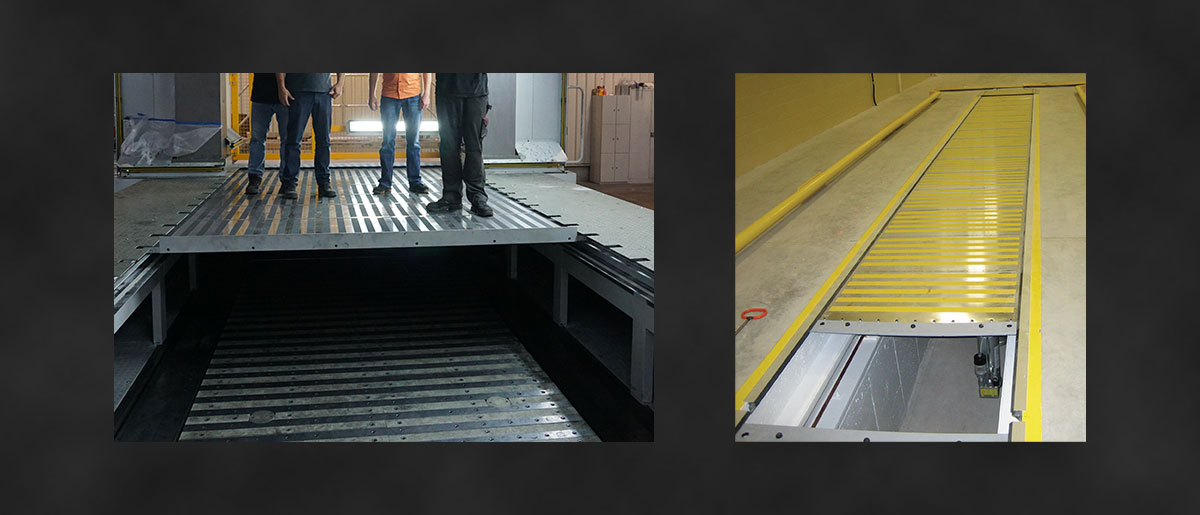

Steelflex Walk-On Pit Covers

Unprotected openings create a fall hazard for workers. A load-bearing roll-up cover provides a walkable surface that co-operates with machine movement. Steelflex® Pit Covers covers not only protect machine ways and actuators from chip loads and dropped tools, but provide a robust walk-on surface that rides flush with ground level. The cover provides easy machine access during maintenance and tool change periods.

Ball Screw Replacement & Reconditioning

Dynatect offers full service repair and refurbishment for ball screws, lead screws, and acme screws. Additionally, Dynatect can reverse engineer, replace, and manufacture new precision ground ball screws. Dynatect can make and repair the most extreme ball screws including units 67 feet long and 6 inches in diameter.

Ball Screw Protection

Telescopic way covers are the preferred way of protecting ball screws and machine ways from costly damage that can stall production. Dynatect can manufacture a replacement cover to stock on hand, so that while the original cover is refurbished to like-new by Dynatect, the extra cover can be installed to minimize downtime.

How Can We Help?

Use our contact page to get in touch with us directly for placing an order, requesting a quote, or getting your products repaired.

Use Our Contact Form