Overview

Key Things to Know about our Ball Screw Repair Service

- Need to get back up and running in a hurry? Please call ahead (+1 (800) 298-2066) to make arrangements for emergency or expedited repair service.

- Damaged Beyond Repair? If your ball screw is damaged beyond repair, we can manufacture a new one from prints or by reverse engineering.

- No Prints? Our team of engineers can reverse-engineer your ball screw assembly to meet your exact specifications.

- Acme Screw or Lead Screws — We can repair them or replace them with a ball screw design.

- Ball screws from any machine tool — no matter what make or model.

More FAQ -Ball Screw Service

Evaluate your repair cost savings with our Ball Screw Scenario Savings Calculator.

Types of Repair

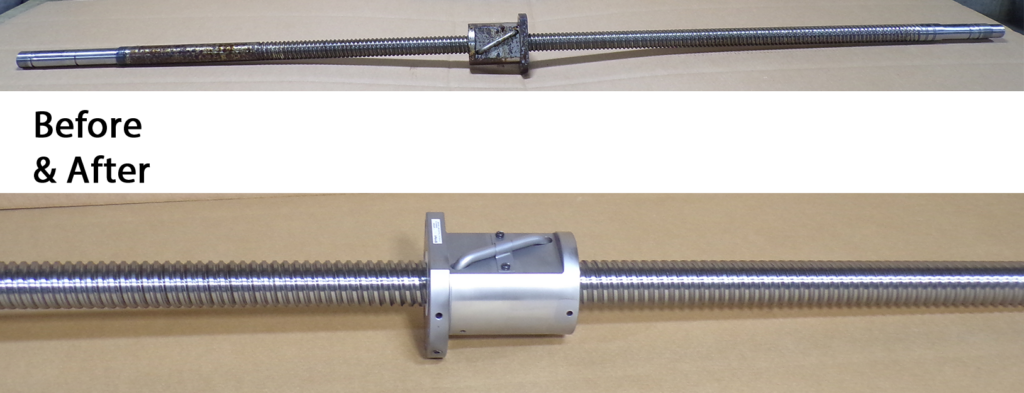

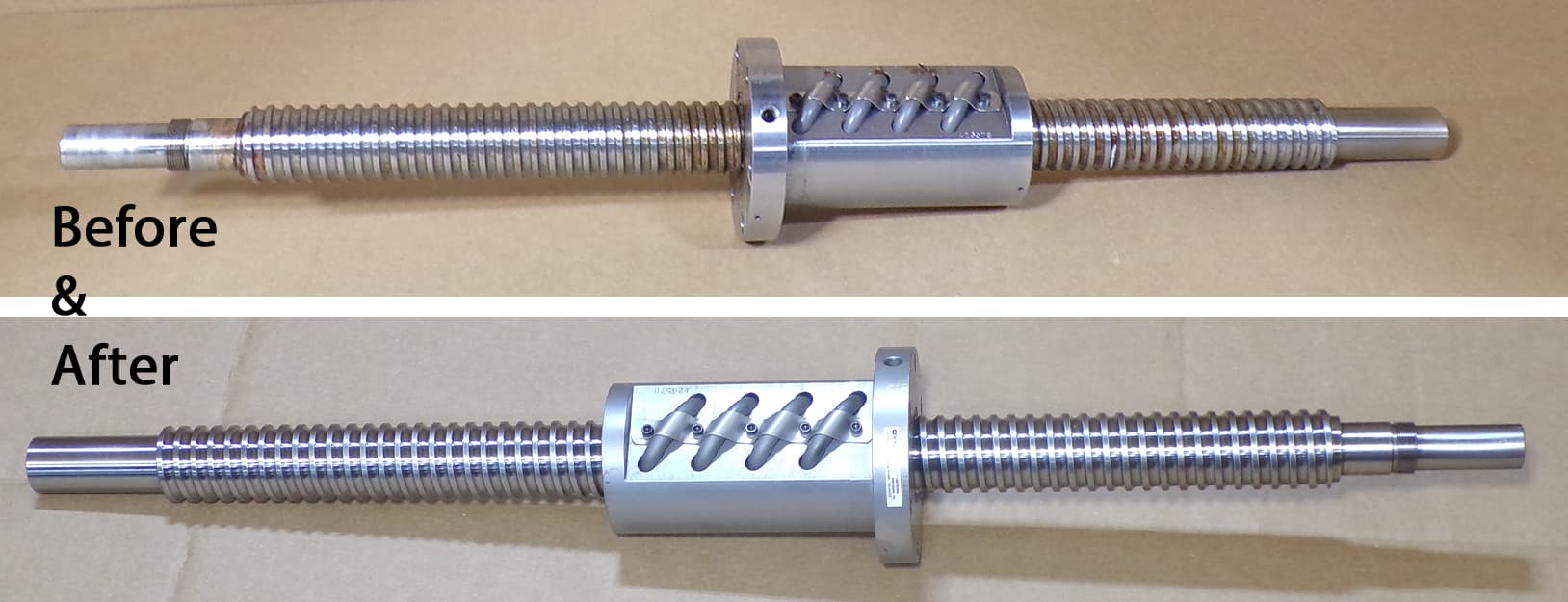

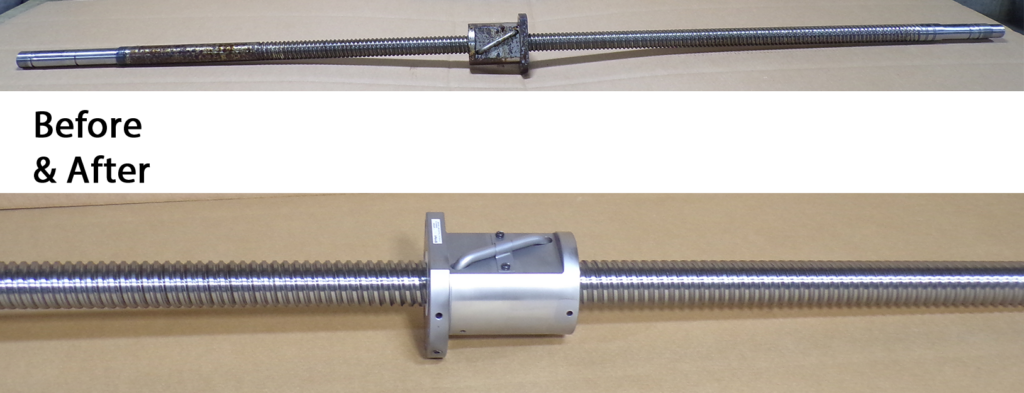

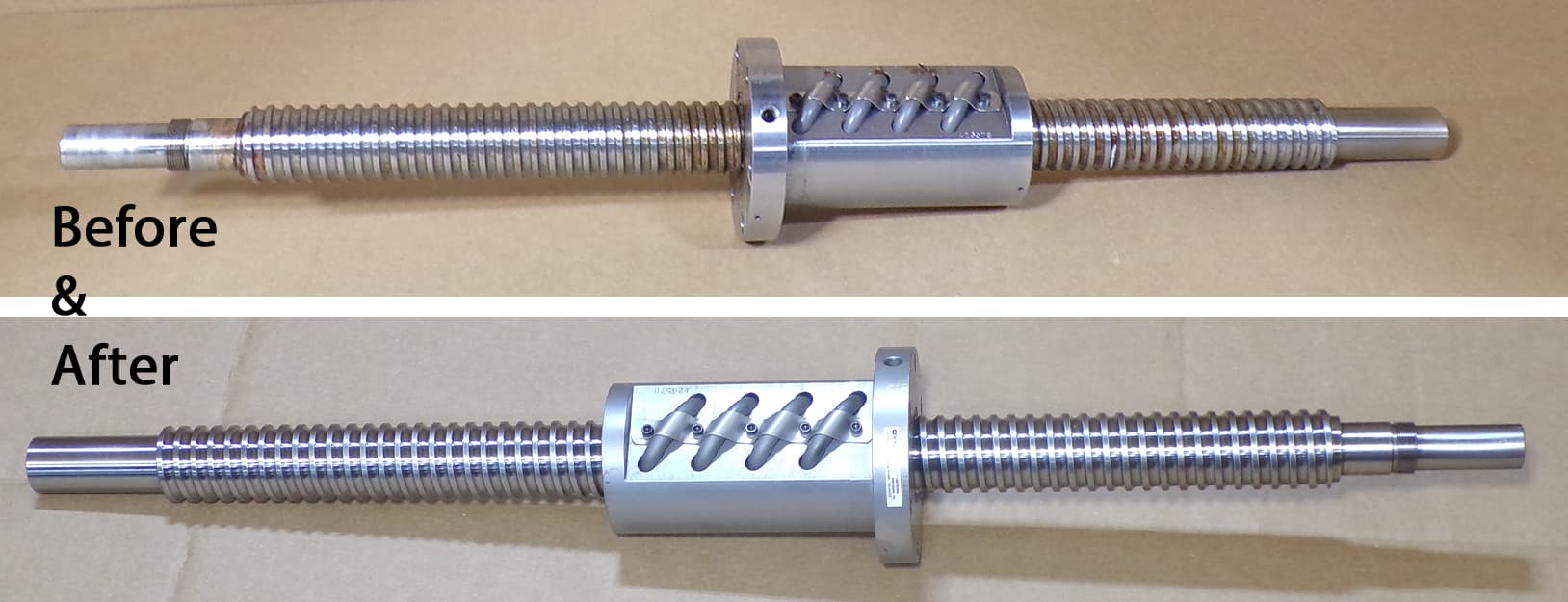

Warranty Reload (Restored to “Like New” Condition)

- The ball screw assembly cleaned and evaluated.

- Visual and physical inspections of the unit are performed to determine if the unit is re-loadable.

- The unit is reloaded with new balls, tested, and inspected to ensure the unit is repaired to “like-new” operating characteristics.

- Particular attention is paid to Smoothness of operation, minimization of backlash, and minimization of dead-band condition.

- Bearing journals, locknut threads, or keyways will be repaired upon customer request.

- One year warranty

- Previously known as “Level 1 Reload”

Temporary Reload (No Warranty)

- The ball screw assembly cleaned and evaluated.

- Visual and physical inspections of the unit are performed to determine if the unit is re-loadable.

- The unit is reloaded with new balls, tested, and inspected.

- “Like-new” characteristics cannot be entirely achieved.

- No warranty

- Previously known as “Level 2 Reload”

Regrind Screw & New Ball Nut

- If after a thorough evaluation, it is found that the ball screw cannot be reloaded due to pitting, brinneling, and/or damage to the interior or exterior of the unit; then the unit could be refurbished by manufacturing a new ball nut and regrinding the existing screw to remove pitting and taper

- One-year warranty.

Typical Evaluation and Repair Process for Standard Reload

- Your ball screw assembly will go through a multi-step cleaning and evaluation process (see below)

- We will produce a report on the condition of the assembly

- We will email you a quote with the option to repair, rebuild, or replace your ball screw assembly

- Run the unit to evaluate the incoming condition

- Disassemble and clean the ball screw

- Check: screw form on comparator; screw for straightness; form of ball nut on surface profiler

- Inspect additional components

- Evaluation running condition, and adjust as required

- Reassemble unit: return mechanism and wipers replaced

- Additional evaluation and inspection for torque error, lead error, etc.

Saving Money, Correcting Problems

At Dynatect LSI, we have been a ball screws manufacturer for over 30 years, and we’ve also been repairing and rebuilding precision ball screws ever since. We’ve seen just about every type of screw, in every condition. We can repair or rebuild your ball screw to save you money and extend the life of your screw before a costly replacement becomes necessary. In addition to quick turnaround times, we offer engineering assistance to correct any problems you might be experiencing with your ball screw application.

Did you know that 30-60% of used precision ball screws can be refurbished to new condition with a warranty? The repair cost is typically 50-60% the cost of new precision ball screws. We quote all ball screw repairs with a replacement option so you can not only compare your cost savings, but have the option of keeping an extra ball screw in stock to avoid replacement lead times. (Dynatect’s new ball screw lead times are still the best in the industry.)

Additional Ball Screw Resources:

Brands Repaired

Brands & Repair Experience

We have experience with many brands, including the following:

| A – C |

D – H |

J – L |

M – R |

S – Z |

| Acroloc |

Daewoo |

Jahn |

MAKINO |

Shoda |

| AM Broach |

DeHoff |

Jones & Lamson |

Mallory |

SIP (Société Industrielle de Precision) |

| Amada |

Demag |

K&T |

Marposs |

SLM Solutions |

| American Lathe |

Denison |

Karl Schmidt |

Matsuura |

Stager |

| Barnes Industries Inc |

DeVLIEG |

Kasper |

Mazak |

Standard Modern |

| Behrens |

DMG |

Kaufmann |

McCrosky |

Starrett |

| Blanchard |

Doosan |

Kearney & Trecker |

Mori Seiki |

Sunstrand |

| Boston Digital |

Ex-Cell-O |

Kearney & Trecker |

Morton |

Supreme |

| Bridgeport |

Fadal |

Keller |

Murata Wiedemann |

SWF |

| Browne & Sharpe |

Feller |

Kempsmith |

Nakamura |

Takamaz |

| Bryant |

Fellows/J&L |

Kitamura |

National |

Takumi |

| Bullard |

Fidia |

Knapp |

Niigata |

ThyssenKrupp |

| Burgmaster |

Fife |

Lagun |

Niles |

TOS |

| Camac |

Forrest |

Landis |

Noblesford |

Tree Mill |

| Carlton |

Fosdick |

Landis Lund |

Okazaki Kikai Seisakusho (Okuma) |

Trippett |

| Carmichael |

Giddings & Lewis (G & L) |

LeBlond |

Okuma |

Van Norman |

| Centroid |

Gildemeister |

Lees-Bradner |

Olivetti |

Waddell |

| Cincinnati Milacron |

Gilman |

Lehmann |

OMAC |

Warner & Swasey |

| Cincom |

Gorton |

Liebherr |

Pratt & Whitney |

Wavetronix |

| Clausing |

Gray |

Linde |

Rainier |

WEBER |

| Colchester |

Greenlee |

Lodge & Shipley |

Reliance |

Weingarten |

| Cone |

Haas |

Lombardi |

Rockwell |

Werth |

| Cosa |

Heald |

Lucas |

|

Wilton |

| Curtiss Wright |

Heller |

|

|

YCM |

|

Hermes |

|

|

Zagar |

|

Hurco |

|

|

|

|

Hyster |

|

|

|

Notes: Above list is not exhaustive. We don’t repair Star Linear SEM units with Adjustable Preload.

Testimonials

Customer Testimonials

“In the early days of our business in the machine tool reconditioning market, we quickly realized that Dynatect’s pricing, delivery and quality beat other ball screw competitors we had solicited. For the past decade, we’ve used Dynatect exclusively and have recommended Dynatect to our customers looking for ball screw refurbishments.

For me personally, I appreciate Dynatect’s arrangement where I am assigned one customer service representative for our communication rather than a generic info@ or customerservice@ email address. I prefer building a working relationship with a single person that I can contact for quotes or with questions or to resolve any issue that may arise and Dynatect’s customer service system allows me to develop that relationship. That’s important to me.”

– Pete, Machine Tool Rebuilder in Wisconsin

“In 2015, the ballscrew failed in one of our 6 imported machines, and the replacement was months out. Called Dynatect, and within 7 weeks we had a new screw in our hands. Fast forward to 2020 and we have purchased 6 screws and each one is the same price and great quality. Fantastic !!

Prompt replies, positive approach, timely delivery, value for our budget …… best of all – just plug and play. My first choice for ballscrew requirements. Keeping us going in Illinois, Tennessee, Kansas and California.”

-Rowland (Plant Manager), Manufacturer of Corrugated Products

“I have always had exceptional service from Dynatect. I regularly send out ball screws for evaluation for reloads and the evaluations are easy to understand. The pricing is very fair. The turn around is quick as well. Lead times on reloads, and new assemblies are always accurate. Which is important.

Nicole is who I work with and she is always very friendly and eager to help. She is quick to get any questions or concerns answered quickly.”

-Trena, Machine Tool Rebuilder in Oregon

“Dynatect provides quality ball screws and delivers quickly even with Reverse Engineering. Quality product and excellent customer service is the best way to describe this company. I had Dynatect make several different ball screws with very good results. Friendly service and professional results on all my purchases.”

-Allen, Engineer at Machine Tool Rebuilder in Tennessee

“Although it would appear that we are competitors, the relationship between Dynatect and PST could not be better. We both manufacture ballscrew assemblies, but we have our own niche and specialties within the market. We have partnered together on a few projects, and have had nothing but success. Dynatect is always prompt and honest in responses to our inquiries, and have always delivered in both quality and lead time. I have only had great experiences working with Dynatect, and I look forward to the future with them.”

-Tony, Sales Engineer at Motion Control OEM

Shipping Instructions

Repair Instructions

Steps

1. Call ahead for an RMA number:

2. Please include a packing slip with:

- Your RA #, name, company, address, and phone #

- Any information that would be helpful in identifying your machine, such as machine name, part number, model or model number, & axis

3. Please ship all items “pre-paid”

- The evaluation is free, however all freight costs are the responsibility of the customer. No freight collect items will be accepted without prior approval

- Shipping Address:

Dynatect Lead Screws International, Inc

2101 Precision Drive

Traverse City, MI 49686

4. Please review our Evaluation Policy

Evaluation Policy

Dynatect is proud to put its years of ball screw experience to work for you. At no charge we will gladly:

► Receive your ball screw assembly (screw and nut only)

► Put it through a multi-step cleaning and evaluation process

► Provide you with a report on the condition of the assembly

► Provide you with a quote to repair the current assembly, and/or provide a quote for a fully warrantied new assembly

Please contact sales prior to shipping in any units that will require disassembly of other components that are unrelated to the ball screw/nut assembly. You may accrue a disassembly fee if the repair department has to disassemble components (i.e. bearings, housings, lock nuts, gears, keys, etc…) that need to be removed prior to the cleaning and evaluation phase. Dynatect reserves the right to charge a disassembly fee before beginning. Once the disassembly fee has been received, we will proceed with your free evaluation of the ball screw assembly. The additional components will be shipped back to you disassembled from the ball screw assembly.

Additionally, Dynatect reserves the right to refuse the free evaluation to customers who have previously not responded to quotes for repair or replacement. If we do not receive a response within 30 days of our evaluation & quote, the ball screw assembly will be shipped back unassembled, and freight cost will be the responsibility of the customer.

If a replacement ball screw assembly is ordered, the original ball screw assembly will be shipped back when the replacement unit is shipped from our facility.