Robotics and Automation

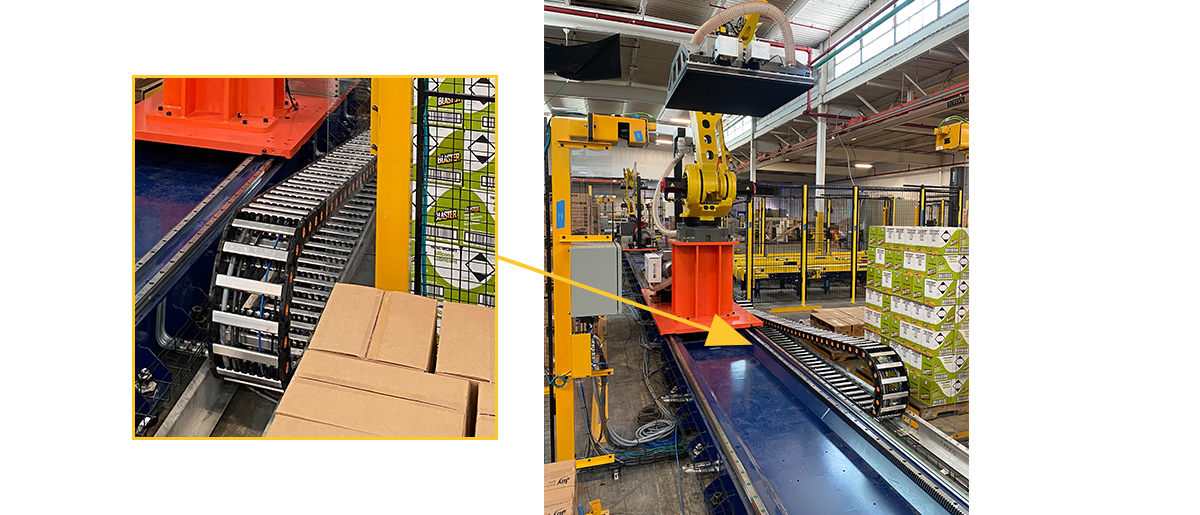

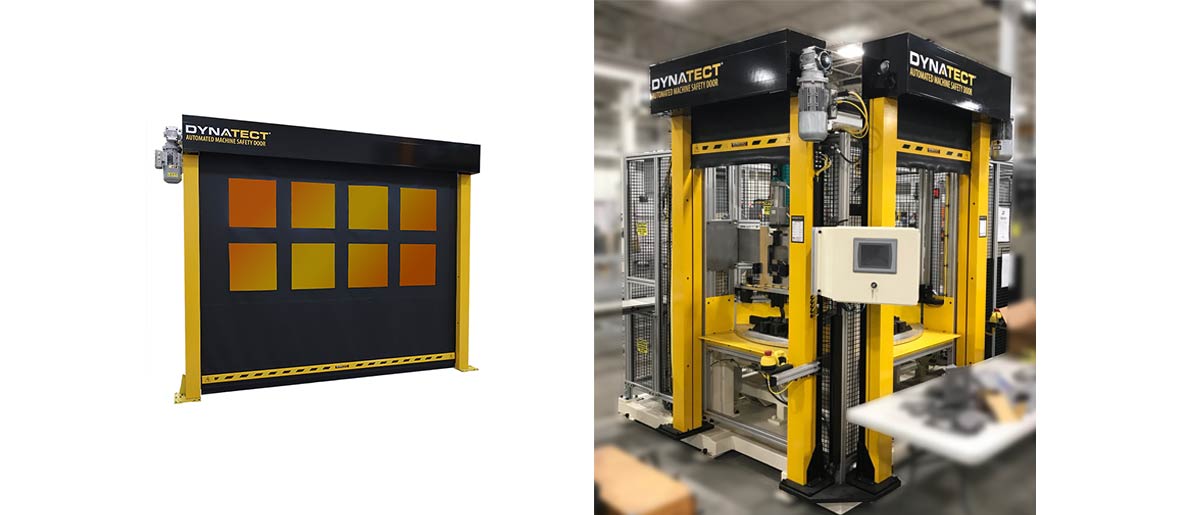

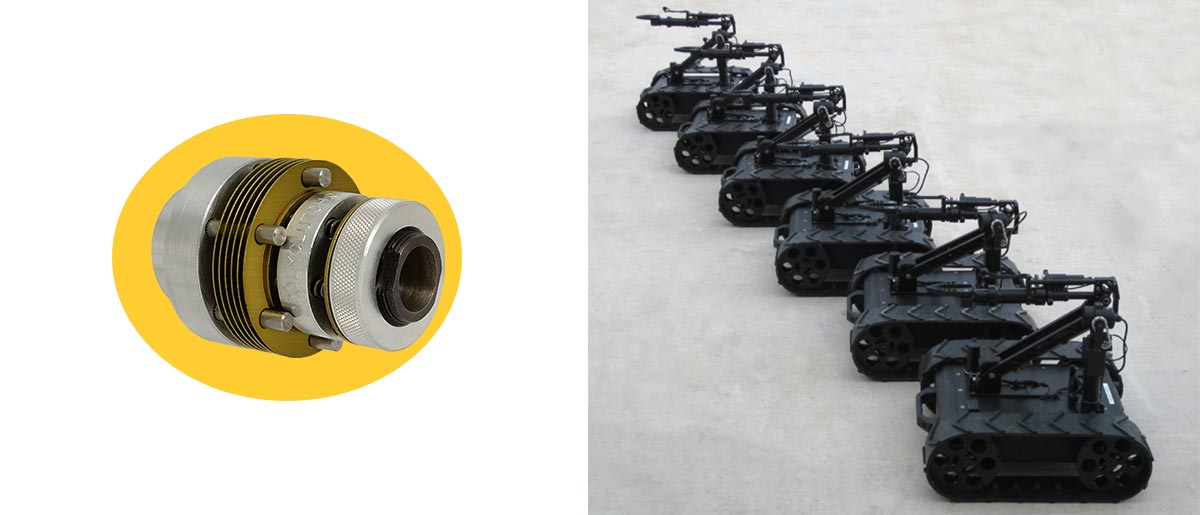

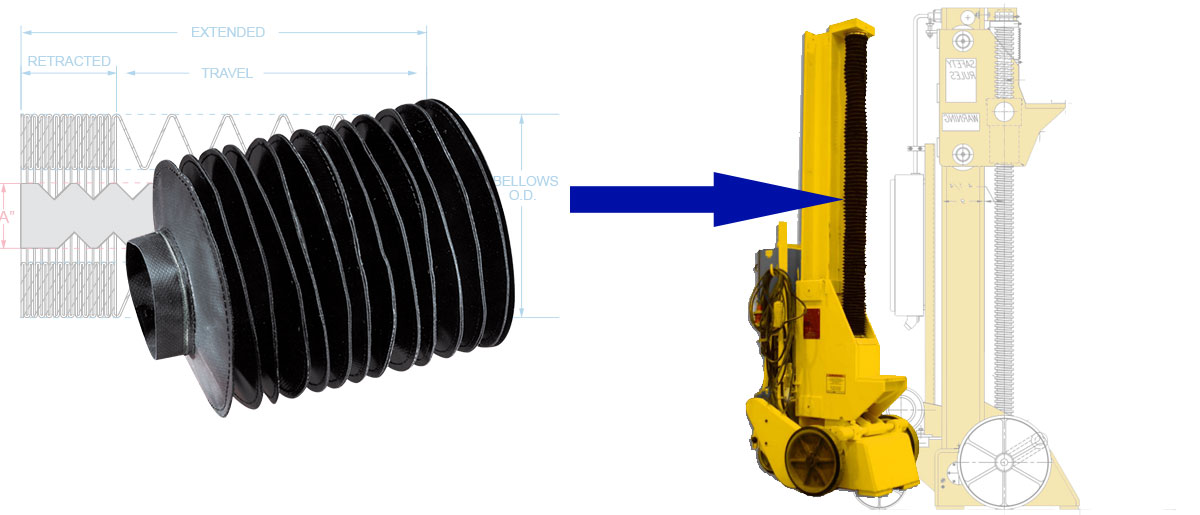

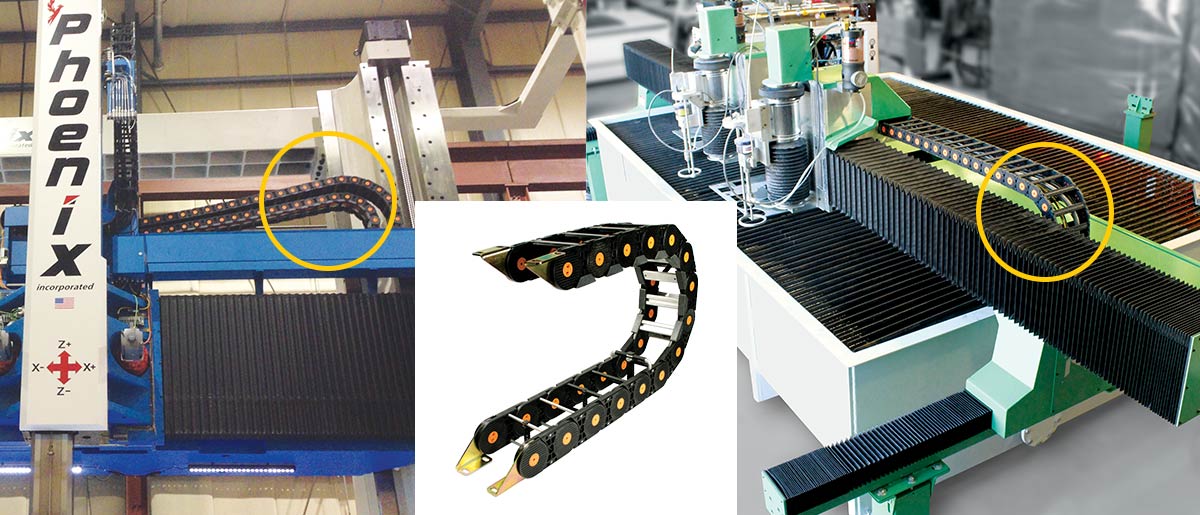

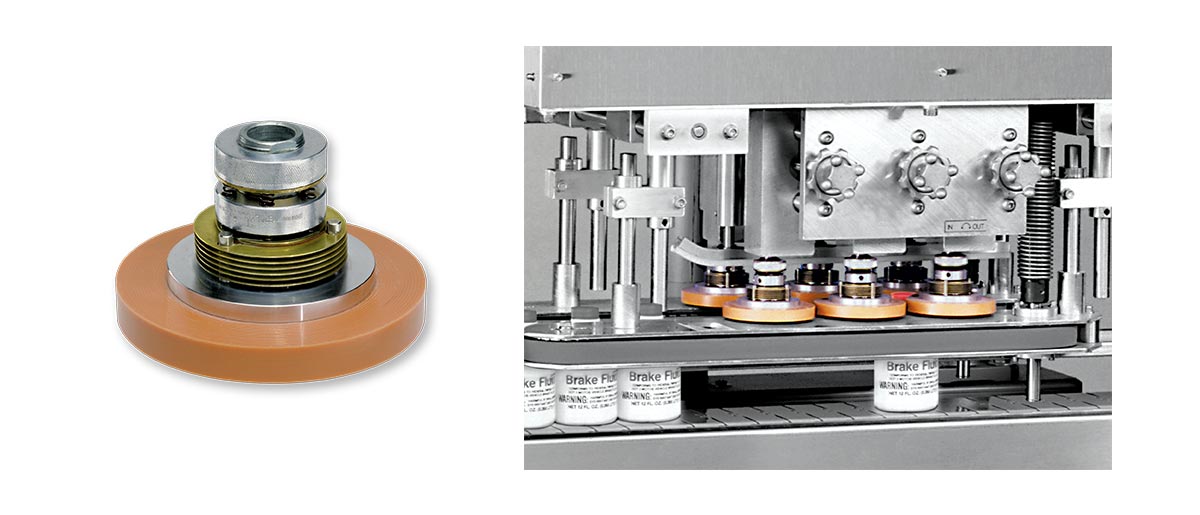

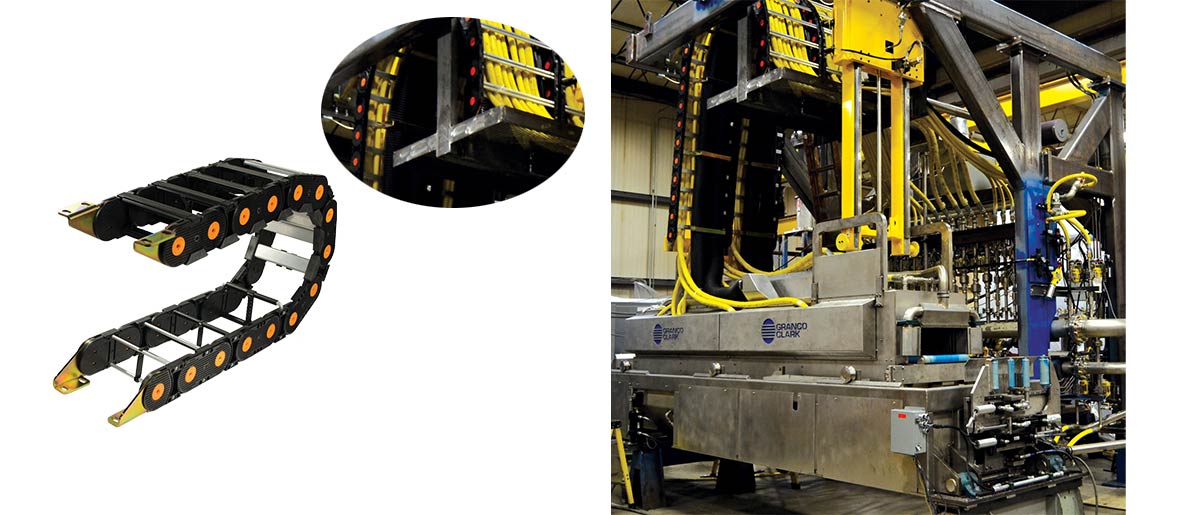

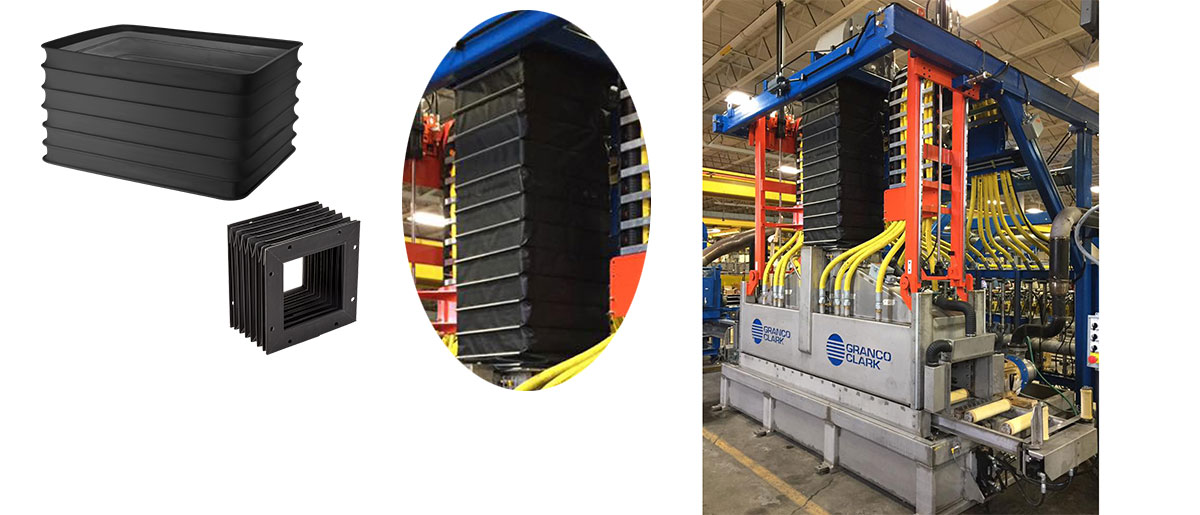

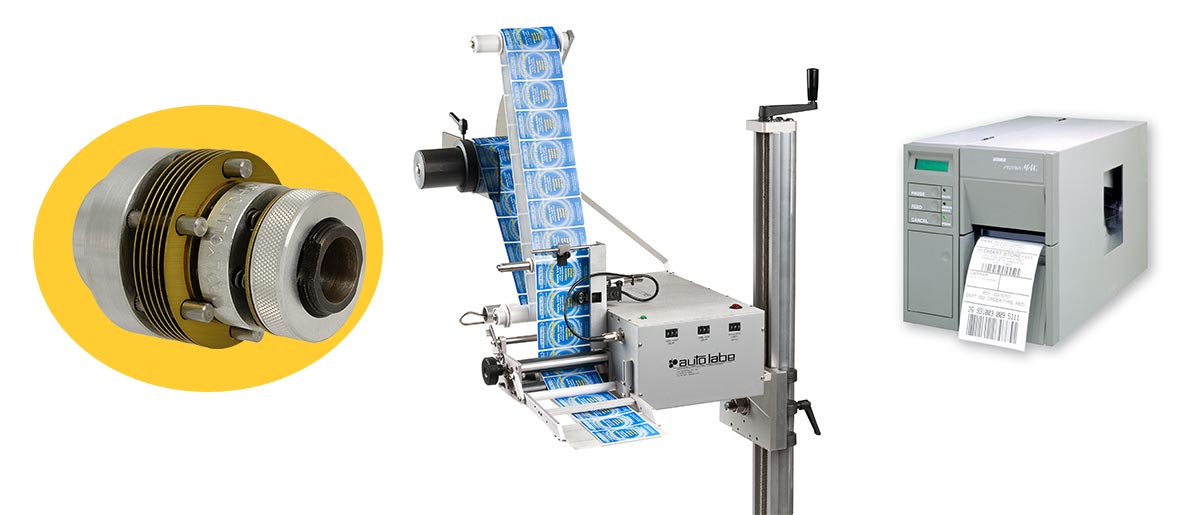

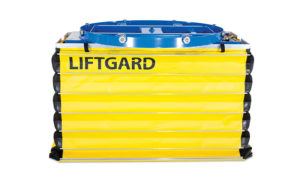

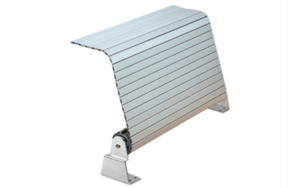

Leading manufacturers, integrators, distributors, and consultants rely on Dynatect for dynamic protective solutions in automation. Dynatect solutions include Automated doors, clutches, cable carriers, manual doors, ball screws, bellows, roll-up doors, and machine-door actuators. Read more below…

Industries and Applications

Automation Sectors:

- material handling, motion control, packaging, converting, printing, automation, semiconductors, and robotics.

Automation Applications:

- automated welding, screws/screw-jacks, automated assembly of finished goods, linear rail/actuators, stamping, pick & place, positioning tables, palletizing, robotic machine-tending, automated storage and retrieval systems (AS/RS), industrial lift tables, printing, levelers, strapping systems, cranes, manipulators, labeling, positioning systems, CNC/cutting systems, process solutions, fastening, door control, PCB/semiconductor/clean rooms, web processes, adhesives, box manufacturing, bottle capping, conveyors, 3D printing, tension take-up, machine centers, and laser welding.

Automation Safety Considerations

- Functionality (acceleration, speed, long travel, loading, watertight, aesthetics, ergonomics)

- Personnel Hazard Protection (containing the manufacturing process):

- Mechanical (noise, vibration, obstacle detection, physical separation, overload protection)

- Fluid (mist, spray)

- Airborne (debris, smoke, fumes)

- Electrical & Electrostatic (accidental discharge)

- Thermal (sparks, heat, fumes, laser radiation)

- Maximizing Uptime (reduce impact from incidental operator interference entering dangerous work stations or cross traffic)

- Safety Distances (ISO 13857 – preventing any breach in a machinery hazard zone for both lower and upper limbs)

- Positioning of Safeguards and Barriers (ISO 13855 – minimum safe distances relative to approach speeds)

- Pinch Points (US OSHA standard number 1910.219)

- Risk/Safety Performance Levels and Compliance (Ple/Cat-4, SILCL3 per EN62061 and EN/ISO 3849, ANSI B11.19 1990 E4.2.3.3.5, ISO 13849-1 Safety-Related Parts of Control System – SRP/CS)

- Welding Applications Compliance (ISO 25980, EN 1598, AWS F2.3, form FDA 3632 laser classes)

- Force and Permissible Kinetic Energy Compliance (EN 12453 and EN 14120)

- Exposure Limits (OSHA 29CFR 1910.132, ACGIH)

- Safety Requirements for Industrial Robots, Robot Systems, & Integration (ISO 10218-1, ISO 10218-2)

How Can We Help?

Use our contact page to get in touch with us directly for placing an order, requesting a quote, or getting your products repaired.

Use Our Contact Form