Plastic Cable & Hose Carriers

Nylatrac® and Nylatube® plastic cable carriers are molded from high-strength glass-filled nylon or special polymers. These carriers are highly durable, corrosion resistance, and are suitable for applications requiring high speed/ acceleration and/or long travel operation.

For plastic (glass-filled nylon) carriers, the standard operating temperature range is between -40F to 250F (-40 to 121 C). Typical applications for nylon carriers are: robotics, automation, pick-and-place, machine tool, and mobile equipment.

Product Lines:

- Nylatube® Standard Plastic – Clean, Lightweight Designs. Enclosed Links

- Nylatrac® Standard Plastic – Clean, Lightweight Designs. Open/Accessible Links

- Nylatrac® Modular Plastic – Greater Strength, Custom Widths, More Accessories

With the Nylatrac Modular line, nylon sidebands and metal crossbars can be combined for additional box strength and lighter weights. Dynatect also offers a true hybrid design for long travel support: a modular plastic carrier with a metallic insert.

Metal Cable & Hose Carriers

Metal cable carriers (aka drag chains) are a durable alternative to plastic solutions for elevated temperatures and heavy-duty loads. Gortrac steel carriers provide superior strength-to-weight ratios and maximum unsupported spans. Fully enclosed Gortube carriers keep out hot chips, coolant, and abrasives. Gortube® chains protect cables and hoses from hot and abrasive elements, and can operate at faster speeds and accelerations.

Product Lines:

- Gortrac® Metal – Superior Strength-to-Weight Ratios, Load-Bearing, and Maximum Unsupported Spans.

- Gortube® Metal– Tube-Style Enclosed Carrier. Protection from Hot Chips. Smooth Operation, Faster Speeds.

Contact factory for any continuous operating temperatures near the minimum or maximums listed below. The standard operating temperatures below are approximate, other variables such as environmental conditions can affect performance.

| Construction | Minimum | Maximum |

| Glass-Filled Nylon (plastic) | -40°F (-40°C) | 250°F (121°C) |

| Plated Steel | -40°F (-40°C) | 140°F (60°C) |

| All Stainless Steel | -40°F (-40°C) | 617°F (325°C) |

| Stainless Steel with Aluminum Crossbars | -13°F (-25°C) | 482°F (250°C) |

| Stainless Steel with Nylon Components | -40°F (-40°C) | 250°F (121°C) |

| Gortube | 32°F (0°C) | 212°F (100°C) |

Finding a Carrier Bend Radius

The minimum bend radius of your cable or hose is critical to selecting a suitable curve height (aka mounting height) for your cable carrier. The carrier’s bend radius should be larger than the recommended bend radius of your stiffest cable or hose. Consult the manufacturers’ cable/hose specification for the recommended bend radius. If you cannot access the data sheets, measure the outside diameter of the largest cable or hose. Electrical cables rated for constant motion typically have a minimum bend radius of 7.5 times its outside diameter. Hoses typically have a minimum bend radius of 12 times its outside diameter.

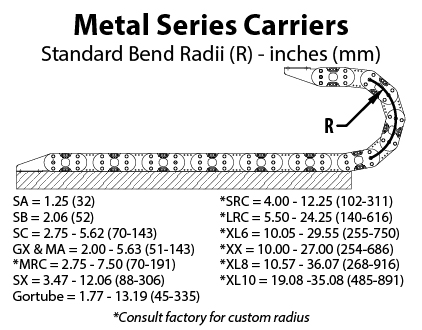

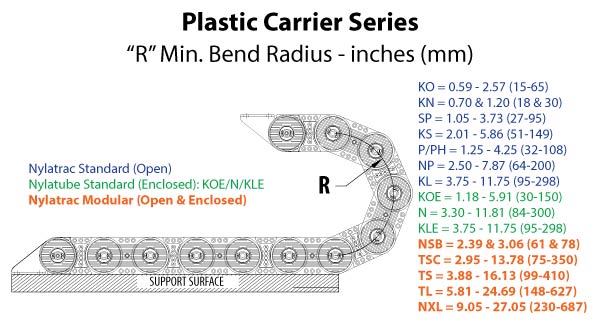

Each product series has a selection of standard bend radii (R dimension). Some metal carriers, as noted, can be supplied with a custom bend radius.

For a quick comparison, the ranges of sizes are listed below.

For a more detailed comparison of sizes, including maximum unsupported span, download our sizing selection guides:

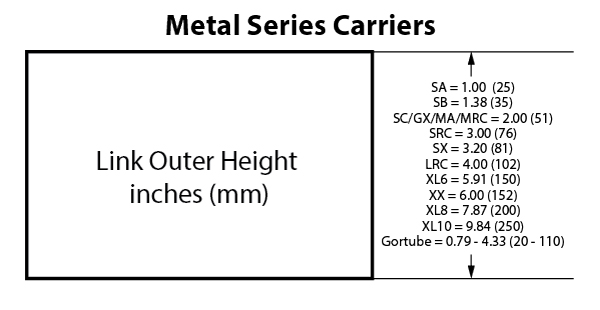

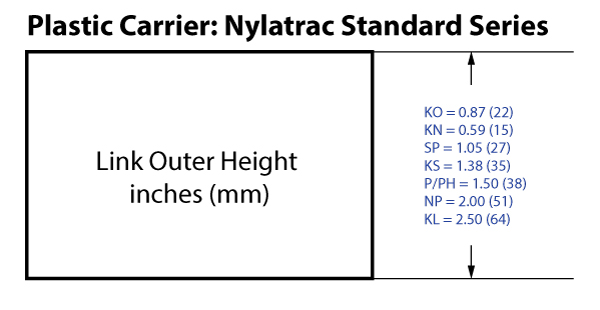

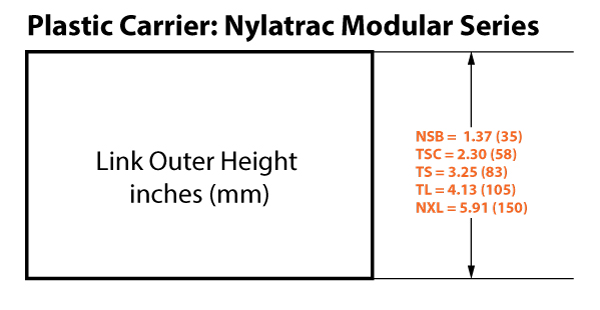

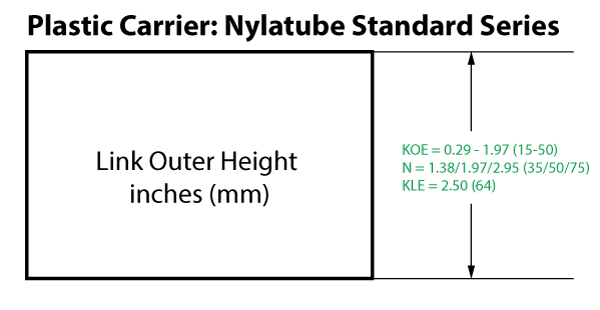

Relative Size: Link Height

For a relative comparison of cavity size, the outer link heights for each brand are listed below. Remember to check the outer link dimensions against potential space restrictions in your application. Consult Product Series specifications for cavity width and height dimensions.