Installation Tips

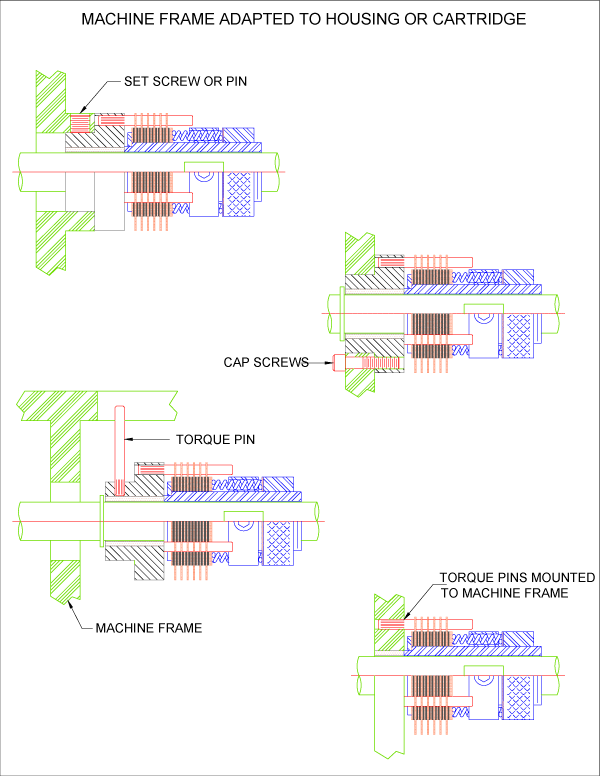

Shaft-through versions: Insert input shaft into cartridge and tighten set screws. Insert housing around input shaft, with torque pins engaging holes in outer plates. Input shaft will keep the cartridge and housing aligned.

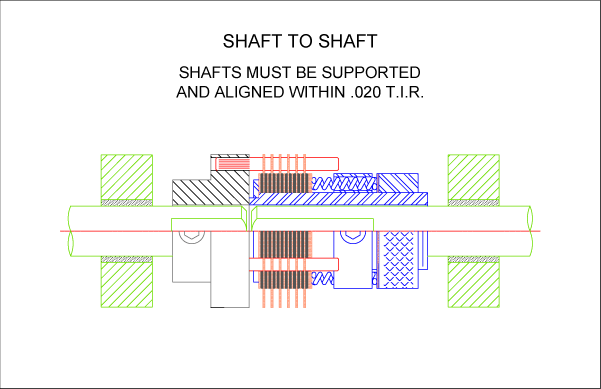

Shaft to Shaft versions: Insert input shaft into cartridge and tighten set screws. Insert output shaft into housing and tighten set screws. Input and output shafts must be properly journaled with centerlines within +/- .010 T.I.R.

Do not lubricate the clutch. Friction materials are designed to run without additional lubrication. Lubrication will cause a change in torque and erratic behavior. The inherent axial loaded design will keep dirt and dust out of the friction surfaces.

Installation Guides by Series:

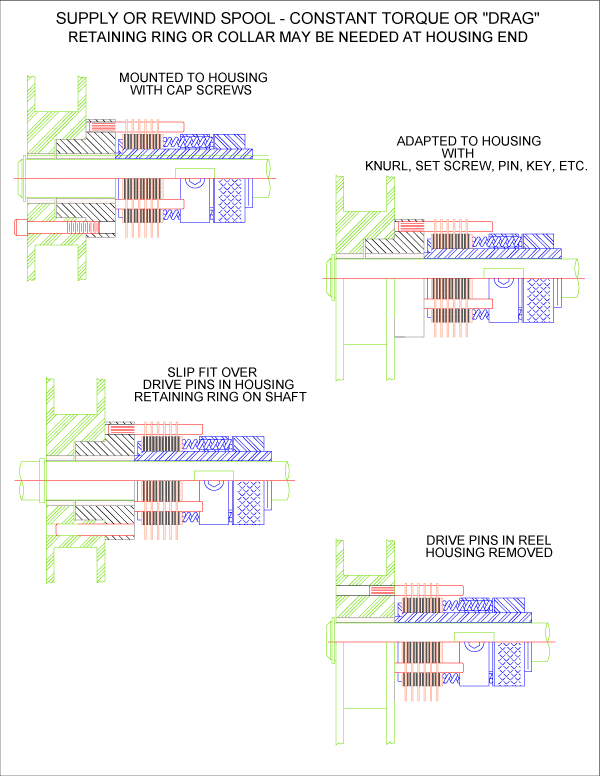

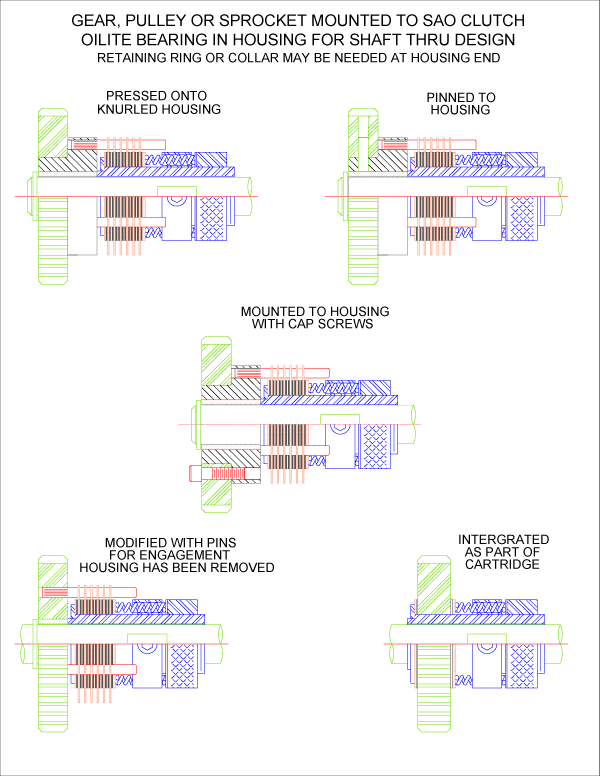

Mounting Examples

All Polyclutch® slip clutches perform the basic function of controlling the torque between two elements. They can be supplied as a shaft-to-shaft coupling or a shaft to pulley, gear, or sprocket model. Polyclutch custom slip clutches can be provided with nonstandard bore sizes, keyways, low backlash or higher torque, minus housings and with pulley, gear or sprocket. Imagination and ingenuity have developed and created additional variations not shown here.

Mounting Application Examples

Note: Outlines in Green are Custom Additions or Customer-Supplied

Shaft to Shaft Mounting Example

Shaft-Through Mounting Example

Machine Frame Adapted to Housing or Cartridge

Supply or Rewind Spool – Constant Torque or “Drag”