Who We Are

Dynatect stands as an industry leader, specializing in the design and manufacturing of custom motion and protection solutions for machines. With over 75 years of experience, we integrate deep application expertise, a diverse product range, and a customer-centric sales approach. Headquartered in New Berlin, WI, and with two plants in the same location, our footprint extends with three additional plants across the US. Dynatect continues to enhance customer experience through new product development and investment in people and equipment to do the job right.

Our Mission: Continuously improve value-added protective devices for equipment and people.

Core Values:

- Safety & Quality

- Continuous employee development

- Innovative products

- Open communication

- Respect for others

- Good citizenship/stewardship

- Physical and emotional wellness

- Integrity

What We Do

Products

Dynatect’s large product portfolio includes textile or metal based components that provide a protective or safety function for industrial or commercial applications. Some recognizable examples include:

- Roll-up doors (equipment access on the side of fire trucks)

- Bellows (passageway joining sections of an extra-long bus)

- Cable carriers (mounted to the telescoping arm of boom lifts)

Customers/Markets

Dynatect makes products for other equipment manufacturers for industries including robots, medical equipment, emergency vehicles, busses, sports equipment, machine tool, construction, and even movie props.

“I am proud to have been included in drawing and designing bellows for Hollywood companies for use in blockbuster movies.” – Evan Crosby, Intern – Engineering

Fun Stuff & Community Engagement

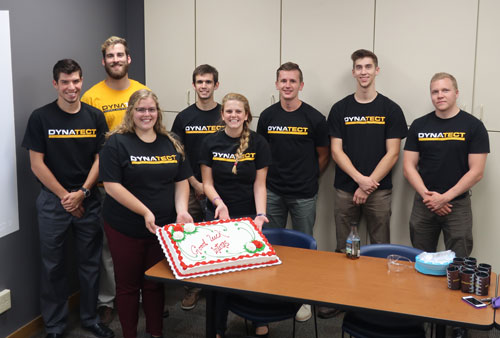

Dynatect and its employees are proud to make an impact on the local community. As an organization, Dynatect supports the community through food drives, blood drives, monetary donations, book and school supply drives. Dynatect’s most recent mission includes collaborating with Habitat for Humanity of Waukesha to support the construction of affordable housing for low-income families. Dynatect employees also know how to have a good time – pictured below is the Dynatect baseball team.

Career Development & Advancement

Like any thriving business, Dynatect is committed to achieving success and fostering growth. We are dedicated to empowering our team members to reach their full potential. At Dynatect, we firmly believe that motivated and hard-working individuals can thrive in our dynamic environment. Want to see how we promote from within? Checkout our social media posts!

Dynatect interns, having selected a project for themselves, led a successful food drive to support the local pantry. Beyond the charitable initiative, winning teams celebrated their achievements with a refreshing water balloon toss – a unique approach that highlights our commitment to cultivating positive team dynamics. This reflects our dedication to community engagement, teamwork, and providing meaningful experiences for the growth of our interns.

Dynatect partnered with MATC to host classes on general leadership skills to help managers or future managers be more effective leaders. Dynatect employees learned how to evaluate leadership effectiveness, demonstrate ethical leadership behavior, apply motivation strategies that improve individual and group performance, and assess personal leadership styles and skills.

Dynatect Internship Program

Dynatect hires about 10 paid interns per year. Full-time hours are available during the summer, and flexible part-time scheduling is available during the school year. Departments include HR, safety, quality, manufacturing, engineering, customer service, and marketing. Dynatect assigns resume-worthy projects with strong management engagement. Dynatect assigns resume-worthy projects with strong management engagement.

Feedback from past interns:

“I greatly enjoyed working on reverse engineering the Bus Bellows as an intern and also being on the team to design VF Doors.” Zach’s philosophy is “Just give it a shot. Ask questions. Try new things. Make mistakes. Learn from them. Fix them. Repeat.” Zach was a summer intern who was hired after graduation as a Design Tech.

“Over the summer, I worked closely with the new product development (NPD) group to design a specialty roll-up door to address the increasing automation market. This was a very challenging design project, but I was still given free rein to use my creativity and knowledge in the design. There was no one standing over my shoulder telling me what to do. Instead, I was given advice and guidance when I needed it. This internship experience provided me with confidence in my design skills as well as the opportunity to work cooperatively with other design engineers. I will be departing Dynatect with skills, knowledge and experiences that I will can apply wherever I end up after I finish school.”

– Danny J.| NPD Design Engineer Intern

“This summer, I built a configurator to automatically generate engineering drawings in Inventor. Of the three internships I’ve had, no company has been more supportive of and committed to their interns than Dynatect. They provided the opportunity to work on challenging projects with supportive professionals who care about my success.”

Sam S. | Mechanical Engineering at UW-Milwaukee

“During my time as a Supply Chain Intern at Dynatect, I was involved with multiple facets of the supply chain from inventory management to ERP implementation and data cleanup. The people at Dynatect truly care about the success of the interns and were great to work with!”

Nick A. | Industrial and Systems Engineering student at UW-Madison

“During my first summer at Dynatect, as an engineering intern, I had the opportunity to develop a new product for Dynatect. This opportunity has allowed me to grow as an engineer and as a professional. This company is not hesitant to give their interns responsibilities, but the employees at Dynatect are more than willing to help interns with any difficulties they may face during their projects.”

Max S. | Mechanical Engineering Major at UW-Platteville

“I created a bellows configurator which reduced quote time from days to minutes. I also developed a methodology to standardize costing practices. Working at Dynatect was an effortless transition because everyone is so helpful and open to assist in any way possible. The lessons I learned this summer will benefit me greatly in my future endeavors.”

Steven | Biomedical Engineering/Software Engineering at Rose-Hulman Institute of Technology

“I am proud to have been included in drawing and designing bellows for Hollywood companies for use in blockbuster movies.”

Evan | Mechanical Engineering at Marquette University

“I had the opportunity to work at Dynatect for two summers, the first one focusing on lean manufacturing and the second one on quality control. Having to develop solutions to quality issues, I worked with all departments to identify root causes and determine corrective actions. Everyone here has been extremely willing to help me with tasks, and been instrumental to our success!”

Matt | Industrial & Systems Engineering at The Ohio State University

“Dynatect has truly given me the tools and knowledge I was looking for and needed to be a productive member in HR. There were plenty of challenges along the way, but people are always willing to help out. I also gained many mentors who care about my success. I couldn’t have asked for more.”

Halle | Human Resource Management at the University of Wisconsin-Whitewater

“Over the course of the summer, I implemented an online Safety Data Sheet program and established a process to keep the program updated. I couldn’t be more proud of the employees I have met at Dynatect. They care about my success and the success of the company.”

Blake | Industrial Studies Management at University of Wisconsin-Platteville