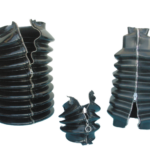

Product Details

Dip-molded bellows can be immersed to create defined hard- and soft areas upon special request. Many mounting configurations are available, including flanges and collars.

Features & Benefits:

- Available in almost any geometry

- Neat, clean appearance with many color options

- Low cost per bellows

- Seamless protection against water, oil and other contaminants

- Excellent UV & ozone resistance

- Suitable for special applications such as food grade and clean room

Applications: Molded bellows protect mechanical components from dust, water, mineral oil and other contaminants. Dip-molded bellows are used in numerous applications:

- Clean-room environments

- medical, robotics and automation applications

- Joint covers

- Joystick/shift covers

Materials:

- Plastisol, a thermoplastic, has good UV- and ozone-resistance, oil- and grease-resistance

- General temperature range: -30 to +80 C (-22 to 176 F)

- Black PVC plastisol is the most common material choice

- Standard grey and white are also available

- Additional colors available for high volume production