Traction Motor Boots

Traction Motor Boots

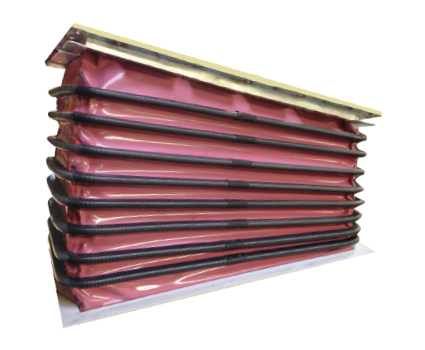

This design is specialized for the ventilation of traction motors on electric locomotives and railcars, serving as an integral part of the cooling air flow as a flexible connecting element between traction motor blower and drive motor. Constructed with seamless tubing in silicone-coated Meta-aramid fabric or other materials, wire reinforcements are fitted inside the convolution peaks. Product solutions for OEM and retrofitting have been optimized for European and North American customers.