The following information is required to design a rotational carrier assembly:

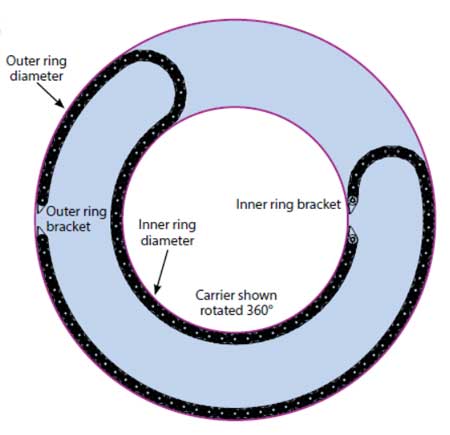

• Degree of rotation

• Inner ring diameter

• Outer ring diameter

• Velocity

• Operating environment & duty cycle

• Fill package

• Mounting location

• Specify which bracket (inner/outer) is rotating

Field Applications & Photos

Field Application

An automatic storage/retrieval system (AS/RS) at a California winery provided consistent, worry-free operation using a 140-ft long Nylatrac Modular (TL-200) carrier assembly. In this side-mounted rotational application, the carrier incorporates both primary and reverse bend radius links where necessary to provide free movement in both directions. Components and accessories were selected to minimize wear and prevent tangling and corkscrewing of cables. (Equipped with poly roller crossbars, low-friction sliders, cavity separators and cable clamps at each end.)