Video: How a Polyclutch Slip Clutch Works

What is a Slip Clutch Made From?

Slip clutches typically contain multiple layers within a compact, disc-like mechanism that includes pressure plates, friction plates, and springs. All Polyclutch® slip clutches perform the basic function of controlling the torque between two elements. They can be supplied as a shaft-to-shaft coupling or a shaft to pulley, gear, or sprocket model. Polyclutch custom slip clutches can be provided with non-standard bore sizes, keyways, low backlash or higher torque, minus housings and with pulley, gear or sprocket. Imagination and ingenuity have resulted in the development of additional slip clutch variations.

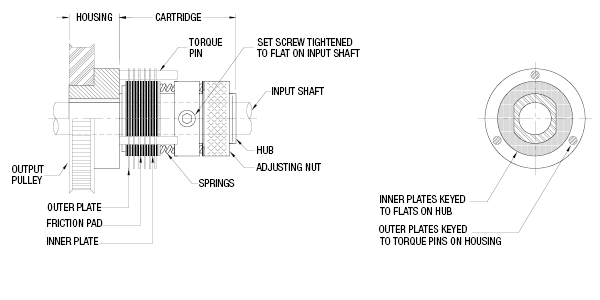

A Polyclutch slip clutch consists of two parts: a cartridge and a housing (see diagram)

The cartridge is set screwed or keyed to the input shaft. The cartridge includes the clutch pack: outer plates, friction pads, inner plates

- Plates are brass with a proprietary finish

- Inner plates are keyed to the cartridge hub

- Outer plates are keyed to the cartridge housing

- Friction pads are a proprietary plastic-based composite (no asbestos)

The housing is either set screwed or keyed to the output shaft, or (as shown), attached to the output gear or pulley, with a bronze bearing to allow relative motion between the input shaft and the output gear/pulley.

How Does a Slip Clutch Work?

Torque is controlled by changing the pressure applied to the clutch pack. In an adjustable style clutch, the torque level is controlled by compressing the springs with the adjusting nut. In a fixed style clutch, a collar is attached to the hub in a fixed position, and the torque level is set by pushing and locking the spring collar to a calibrated position.

Tolerances, Backlash & Break-In

All slip clutch torques are calibrated to +/- 20% but can be held to closer tolerances. Please discuss your requirements with Dynatect engineering.

Backlash of 6° is standard for Slipper models and 2° for the Slip-Ease models. Slipper models can be held to 2° if required.

Our proprietary burn-in process insures that all clutches will perform consistently right out of the box, with no break-in period required.

Exploring the Spectrum: Types of Slip Clutches

In the vast field of mechanical components, slip clutches are essential for augmenting machinery efficiency and safety. Recognizing the diverse requirements across industries, Dynatect, alongside other leading manufacturers, offers a variety of slip clutch types:

- Mechanical Friction Torque Limiting Slip Clutches: These clutches are ideal for applications requiring precise torque control, enhancing operational safety and reliability by preventing mechanical overload.

- Toothed Jaw Clutches: These clutches offer a robust solution for applications that demand high torque transmission without slip, making them suitable for high-power, synchronized operations.

- One-Way Clutches: Perfect for applications requiring rotation in one direction while freely spinning or locking in the other, these clutches provide smooth operation and efficiency in various mechanical systems.

Each type of slip clutch has its unique features and applications, contributing to the versatility and efficiency of mechanical systems across industries.