Design Applications

Overload Protection: Intended to protect motor, machinery, and/or operator. Clutch will slip when mechanism is jammed. Motion will continue when impediment is removed.

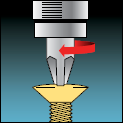

Torque Control: Screw bottle caps, screws, controls, etc., to correct torque setting. Combine with one way clutch to slip at rated torque in one direction and freewheel or positive drive in other direction. Allows repeatable, accurate torque for capping machines, automatic screw driving, valve control, etc.

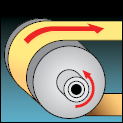

Tension Control: Maintain constant tension while winding or unwinding wire, paper, film, thread, etc. Slip clutch automatically compensates for changes in speed and diameter. Pneumatic clutch can change tension during operation.

![]()

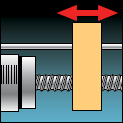

Force Control: Push product against gate with constant force. Remove gate and move to next position. No damage to product or conveyor – clutch does all the slipping. Also used for overload protection when jammed and for indexing the conveyor.

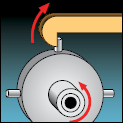

Position Retention and Brake: Hold lid, cover, door, screen, etc., at any position. Fingertip control. Combine with one way clutch for free movement in one direction. Ideal for friction hinges when smooth movement of lids, doors, screens, covers, etc., is required

Indexing: Hold index wheel with solenoid operated pin. Motor runs continuously with clutch slipping. Pin pulls back to index to next station. Can be single or partial revolution. Can index tables, conveyors, vending machines, controls, etc.

Soft Starts/Cushioned Stops: Inertia makes clutch slip when starting and/or stopping. Results in less shock throughout the system. Ideal for slip at the end of stroke.

Automotive Applications

Dynatect offers small, tight tolerance clutches in high volumes for vehicle applications including:

- Protecting automatic door/hatch drive mechanism from human-applied overload or interference

- Autonomous driving vehicles that need the steering wheel to slide, fold, or break-away to allow control in the event of electrical failure

Conveyers

Polyclutch slip clutches offer an added level of safety and protection to both the machine and its operators.

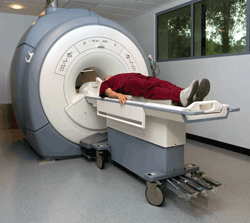

MRI Beds

Polyclutch adds a mechanical safety for moving MRI beds as seen in this picture.

Military & Law Enforcement Inspection Robots

The Machine Lab, Inc., an industry leader in defense robotics, uses two Polyclutch slip clutches in each robot arm for overload protection.

Label Printers

Polyclutch slip clutches are the perfect solution for adding just the right amount of tension to any reel or spool without having to worry about the tension varying over time or wearing out prematurely.

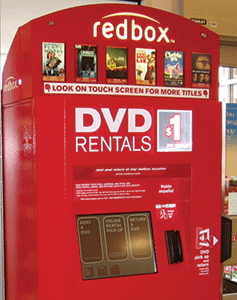

Retail Vending Kiosks

A Polyclutch protects this machine against any type of overload or jamming during the process of dispensing a DVD.

Ice-Dispensing Machines

Hidden deep inside of this ice-making machine, a Polyclutch slip clutch prevents overload to the drive mechanism during the forming and dispensing of ice cubes.

Automated Kiosks

Polyclutch slip clutches are an integral part of many retail kiosks. As shown in this photo, a slip clutch is used to protect the sensitive drive mechanisms of these automated machines.

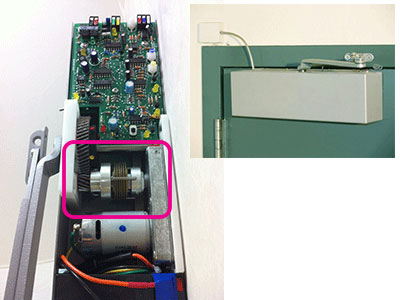

Disabled Access Systems

A Polyclutch slip clutch provides safety in many disabled access systems. In this automated door opener, a clutch is used for overload protection.

Constant Torque for Printing Applications

A slip clutch acts as a continuous drag brake to meet specific torque requirements for an unwind/rewind system application in a bar code printer. Other applications apply constant tension to film, wire, thread, paper, etc.

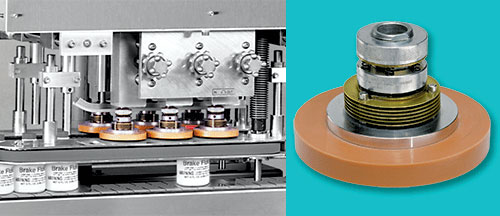

Bottle Capping Applications

Adjustable slip clutches control the precise amount of torque to tighten bottle caps without wear or breakage in this capping line application. All the slippage is in the clutch, with no appreciable wear.

→ Contact us today (800-298-2066) to discuss your application or use our quote request form to tell us about your application.

→ View Selection Guide