How to Select the Right Slip Clutch for Your Application

Three key factors in determining the right clutch are the maximum shaft size, torque capacity of the clutch, and wattage capacity. Please consider the limitations listed for each Polyclutch product line.

- For torque adjustment while clutch is in use (remote torque adjustment), see the Slip-Aire clutches.

- For applications outside of these general limitations, please consult Dynatect

The clutch capacity is based on continuous operation at 50 RPM for over 25 million cycles. Torque, RPM, duty cycle and life are interdependent. A reduction of any of these will allow an increase in any other. (Running at 25 RPM will allow twice the torque, or running for only 10% of the cycle will allow higher RPM, etc.)

The limit is based on heat buildup measured in watts per:

Watts = Torque (inch pounds) x RPM x Duty Cycle* x 0.011.

*(% of the time the clutch is slipping, expressed as a decimal. For example, 0.5 = 50% of the time the clutch is slipping)

Please contact us to discuss high torque, high RPM, and rapid cycling applications.

Design Advantages & Limitations

Design Advantages

- Smooth, reliable breakaway and continuous slip

- Proprietary burn-in process = no-stiction: static friction lower than dynamic friction

- No-break in period: Precise torque with consistent repeatability from day 1

- No sudden shock on sensitive paper/film/wire/thread, etc.

- Long life of 20 to 30 million revolutions in slip condition

- Torque range from 0.5 lb-in to 1000 lb-in

- Fixed, adjustable and custom designs

- Clutches are bi-directional

- No lubrication needed

- Lower cost alternative to servo motors

- More compact/smaller and less expensive than magnetic clutches

- No reset required, no clicker (compare to ball detent)

- Offers mechanical safety in mechanically controlled systems

- American engineered and made in the USA

Design Limitations

- Max. 1.25″ shaft size on a through-shaft

- Min. 1/8″ (3mm) bore size

- Max. 1000 lb-in torque limitation

- Not to be used as a universal joint or a spring coupler

- Does not de-couple at overload

- Cannot be exposed to radiation

- Contact a Polyclutch application specialist if slip clutch would be directly exposed to weather or wash down

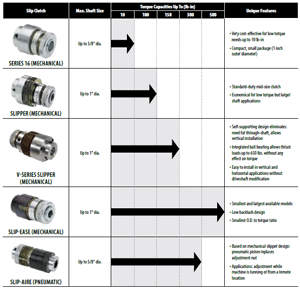

Slip Clutch Line Overview

SERIES 16

- Mechanical friction clutch

- Our most affordable slip clutch

- Can accommodate shaft sizes up to 0.375 inch

- Torque capacities of up to 20 lb-in

- Available in a fixed torque or adjustable torque configuration

- Go to product specifications >

SLIPPER CLUTCH

- Mechanical friction clutch

- Our standard-duty slip clutch

- Can accommodate shaft sizes up to 1 inch

- Torque capacities of up to 500 lb-in

- Available in a fixed torque or adjustable torque configuration

- Go to product specifications >

V-SERIES SLIPPER

- Mechanical friction clutch ideal for vertical mounting orientation

- Torque control for driving, capping and other applications where thrust loads are applied

- Can accommodate shaft sizes up to 1 inch

- Horizontal and vertical installation without driveshaft modifications

- Integrated ball bearing allows thrust loads of 150 to 650 pounds

- Torque capacities of up to 150 lb-in

- Go to product specifications >

SLIP-EASE

- For applications where space is at a premium and low backlash is required

- Can accommodate shaft sizes up to 1.25 inches

- Torque capacities of up to 1000 lb-in

- Available in a fixed torque or adjustable torque configuration

- Miniature size 12 version has extremely small footprint of only 3/4″ in diameter

- Go to product specifications >

SLIP-AIRE

- Pneumatic friction slip clutch

- Can be adjusted remotely while the machine is in operation to accomplish quick, repeatable, accurate setup

- Can accommodate shaft sizes up to 0.625”

- Torque capacities of up to 300 lb-in

- Go to product specifications >