Product Details

Designed for Challenging Environments

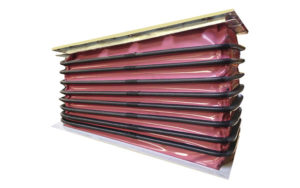

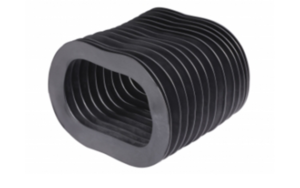

Bus bellows, also known as intercar joint bellows, are constructed of aluminum extrusions shaped to provide structure and strength to a variety of materials including durable, elastomer-coated fabrics. Materials are chosen to conform with these challenging environmental conditions and regulatory requirements:

- Harsh weather

- Withstand continuous flexing

- Light debris

- Fire retardant requirements

- UV exposure

- Longer life and low maintenance

Download Literature/Resources

Bus, Train & Light Rail Bellows Capabilities

- Dynatect manufactures drop-in replacements for Dynatect and other OEM bellows (lower cost alternative with same design)

- Dynatect can provide complete bus bellows or separate components for replacements driven by:

- Collisions impacting only one side of a bus

- Floor deterioration due to weather or salt

- Vandalism like cuts or graffiti on the bellows

- Existing bus bellows designs include: Standard, Extended / Full Roof Cap (cover roof-mounted accessories on the bus and provides continuity with upper bus fairing for aesthetics), & BRT (New Flyer Bus with special shape)

- Dynatect can reverse engineer and provide prototype of an existing design if not already in our portfolio. Coordinate in advance providing an existing unit for evaluation.

- Easy Mounting – simple features and connection points between components that minimize replacement time

Field Applications

Amusement park monorail bellows (below)

Connecting bellows for articulated bus (below)

Case Study

Dynatect’s Replacement Bus Bellows Field-Tested by Midwest’s Largest Transit Authority

Bellows replacements occur because of normal wear and tear, and due to exceptional abuse including accidents. Normal wear and tear vary greatly by the geography, some which may have more ice melting chemical and sand usage or degraded road conditions. The floor components which seal out the bottom of the bellows have a significantly higher replacement rate due to the floors’ proximity to road debris.

Selecting the vendor for replacement components has several factors to consider. This includes if multiple bidders are required, responsiveness, OEM vs. aftermarket components, quality, availability, and price. Many properties may not even be aware that there are aftermarket replacement options.

A Transit Authority (TA), located in the Midwest, has more than 300 articulated buses in its fleet. In 2017, this TA was evaluating alternate sources for a large overhaul project of 208 articulated buses. While evaluating OEM components, they also evaluated Dynatect for the aftermarket replacement components required.

The TA was familiar with Dynatect’s performance because 100 of their articulated buses are outfitted with Dynatect OEM bellows. For this project, the TA sought improvements to replacement parts for bellows made by another OEM provider. The engineering teams of Dynatect and the TA discussed improvements, many of which came from TA’s familiarity with Dynatect’s design. One cost savings improvement included a two-piece design allowing for a partial replacement when damage is isolated to a portion of the floor. A durability improvement included changing the floor fastening mechanism from a rubber/button approach to an extruded aluminum mounting strip; this reduced interference and improved installation and maintenance. An integrity improvement included a heavy-duty channel that connects the end of each aluminum support rib of the bellows replacing a lighter channel design that was prone to deformation.

Dynatect produced a road field test prototype which the TA installed along with Dynatect installation personnel. Subsequent to road testing, the TA and Dynatect jointly evaluated and further collaborated on the design. One post-test improvement included adding mounting slots to accommodate inconsistencies in the original installation. Another post-test improvement included sealing out small gaps. Ultimately, the custom TA design resulted in easier and faster installation.

Through the above process, the TA was confident they now had the most cost-effective and high-performance solution – confirmed by field testing. The TA subsequently updated their source specification identifying Dynatect as the bellows floor supplier for the project. Dynatect remained a strong partner through deployment, balancing volume and lead time to support the project.

Dynatect has decades of experience as an OEM manufacturer of articulated bus bellows. Dynatect has been manufacturing bus bellows for 36 years with more than 4000 bellows produced. In addition to new bus bellows, Dynatect also provides replacements for bus bellows made by any manufacturer. Featured in over 40 transit properties and commercial entities, including well known theme parks. This has established the quality and durability of Dynatect offering.

More Transportation Bellows Applications

Dynatect has experience supplying custom bellows for similar applications in transportation, such as:

→ Visit our Transportation Industry Page

Specs

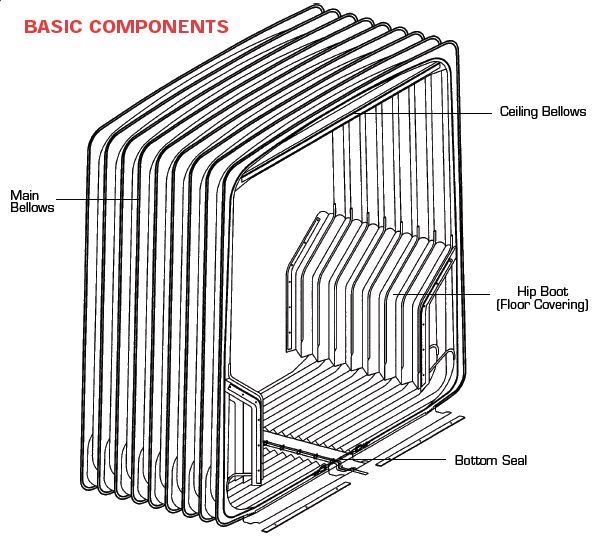

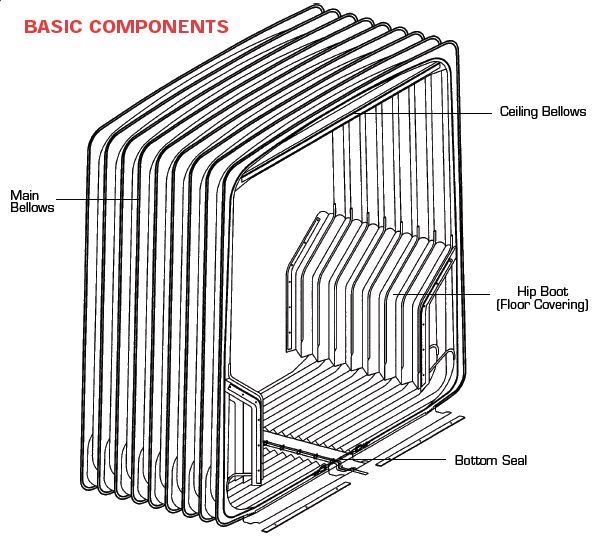

Basic Bus Bellows Components

The components of bus bellows include:

- Main Bellows / Folding Bellows:

- Inside valley of each convolution is stitched and then has an aluminum-extrusion crimped-on to provide support for the false-ceilings and hip boots

- Outside peaks of convolutions are captured with a crimped aluminum-extrusion

- Dynatect bellows incorporate easy-to-use mounting clips that don’t require tools for installation; competitors clips must be manually screwed-in to the ceiling or hip boots.

- Hip Boots / Floor Cover/ Floor Skirt:

- Dynatect provides new and replacement hip boots

- Dynatect provides replacement / retrofit hip boots for legacy designs with drop-in extrusions and clip technology

- Front and rear units are required for both street and curb sides

- Floor Assembly:

- Dynatect makes one-piece and two-piece drop-in floors

- Selecting the two piece design allows replacement of only half a floor if only damaged on one side.

- Dynatect’s floor material, rubber, and connecting channels are thicker and more robust than competitors designs.

- Bellows Mounting Seal:

- Bulkhead Mount and Center Hoop Mount

- False Ceilings / Roof Cover:

- Mounts with in a tongue and groove arrangement using either folding or solid plastic clip

- Multiple designs shown and available

- Extensions & Roof Caps

- Cover CNG tanks, batteries, power cables, etc