Real Savings and Reduced Downtime

Those who have not previously pursued ball screw repair may be surprised to learn that 30-60% of used PGBS can be refurbished to new condition with a warranty. Further, the cost of those repairs is typically just 50-60% the cost of new PGBS. For managers with cost reduction initiatives, a 25% net savings across the population of annual PGBS purchases is significant to reconsider.

Reducing machine downtime is another way of saving cost. While downtime costs vary, in high-volume situations that time can add up to significant costs. With industry lead times running anywhere from 6 to 50 (!) weeks a good way to reduce that downtime is by stocking PGBS. Combining these two strategies, a repair program and a stocking strategy, can reduce downtime by nearly 90%. Whether it be a new or refurbished having a PGBS on the shelf could save the day.

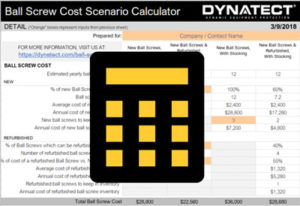

Dynatect LSI has introduced a savings calculator to evaluate both potential cost savings and reducing downtime. There are 10 inputs to flexibly model your specific company/application such as the number of machine uptime hours in a working day. It also provides guidance on typical ranges for unknown values. The output includes comparison of downtime day reduction, along with total ball screw cost and emergency downtime cost. The output can be saved and shared with other stakeholders in evaluating different practices to achieve different performance metrics. This tool can empower your team financially justify repair and stocking options.

One key to balancing new PGBS, refurbished PGBS, custom legacy equipment, up-time, and stock is a supplier who can provide the widest range of options. Machine tool owners often leverage a combination repair, emergency stock, and replenishment – for which Dynatect remains ideally positioned to provide all three services and provide a comparison calculator to compare those. When unique designs, large sizes, or new ball screws have long lead-times, reliable repair can ensure mission-critical production machines are online faster. Dynatect currently offers some of the industry’s widest options and fastest deliveries for Precision Ground Ball Screws.