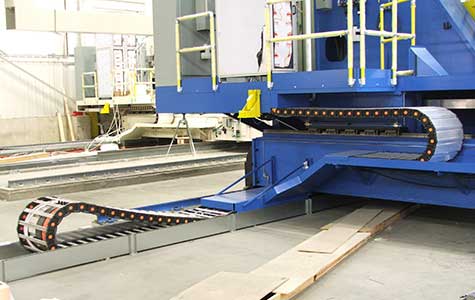

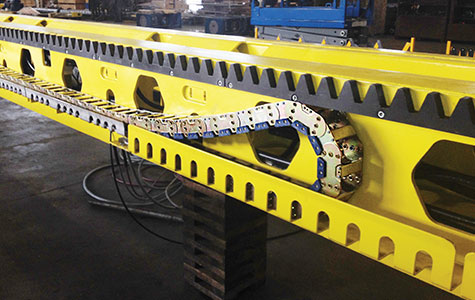

Dynatect customized a steel cable carrier for increased box strength to handle the vibration experienced by the carrier during operation. Pictured installation is a planter with an 88’ wide extension.

Nylatrac® Modular TS and TSC carriers installed on custom pick-and-place equipment provide cable/hose management for long travel and three axis of operation.

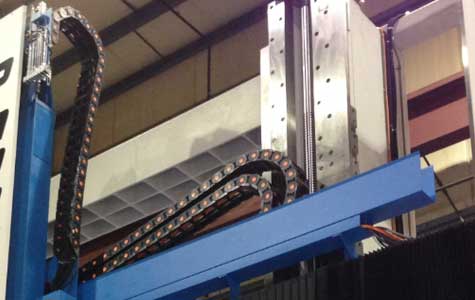

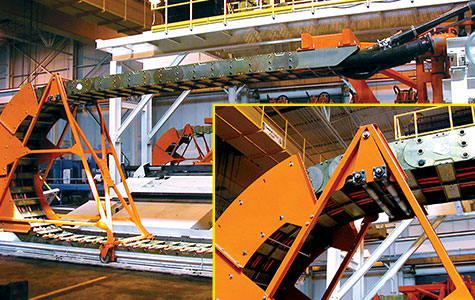

Nylatrac Modular TL carriers designed for long travel on a multi-axis riveting machine. The open-style carrier (lower left) is equipped with aluminum flat bars and low-friction modular sliders in a lowered mounting height configuration. The enclosed-style carrier (upper right) shields cables from ejected rivet heads and debris with heavy-duty bolt-in aluminum armor plates.

Nylatrac NP Series plastic cable carriers installed on a gantry crane designed to offload product to an automated cart-shuttling system.

Cows and cable carriers together? Nylatrac® Modular TSC carriers manage the cables and hoses connected to a Roboleo automated milking robot. Cavity separators placed every link prevent the hoses from sagging, and replaceable modular sliders on the side-mounted carrier protect link side bands from excessive wear.

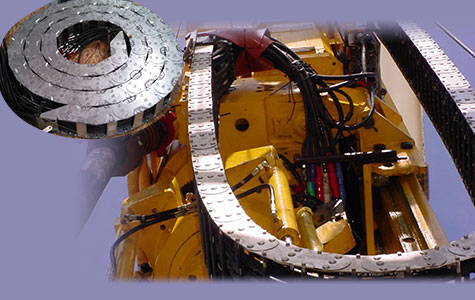

Nested Gortrac SRC Series carriers protect and guide hoses on this horizontal directional drilling machine by Universal HDD™.

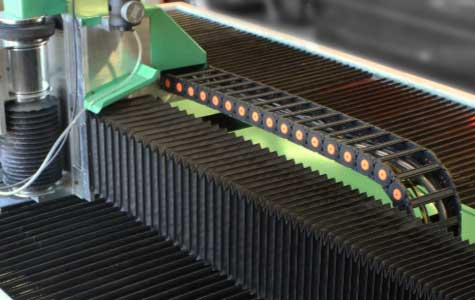

Nylatrac Modular carriers on a high-speed waterjet machine.

A paving screed designed for paving wider roads and surfaces uses a Gortrac SX Series carrier to guide the power cables as the slide track telescopes to the required width.

Nested Gortrac steel XL carrier system used on a large machining center for the aerospace industry.

Cable and Hydraulic Hose Protection for Drill Rig: Gortrac steel carrier installed on a Universal HDD Slant/Vertical Drill Rig (ADI 360 VS).

Enclosed-style Gortrac steel XL carrier in steel cable heat-treating application for unsupported long travel. Armor plates protect cables in aggressive environments.

Nylatrac Modular plastic carriers on a large vertical machining center.

Walking Travel System: Stainless steel Gortrac drag chain for 120 feet of travel, with 2-piece glide shoes for a superior gliding system. Equipped with flat aluminum separators and 30″ wide bars for optimal cable/hose life.

Custom Gortrac® stainless steel LRC carrier maintains cables and hoses on an oil rig platform. Dynatect supplies custom steel drag chains to the oil and gas industry.

Offshore Drill Rig – Skate System: Custom Gortrac drag chain with low-friction glide shoes and bolted aluminum flat bars.

These Modular Nylatrac carriers are attached to pipe handling equipment for the offshore oil and gas industry.

Blow-molding application with Gortrac steel XL carrier with patented “Walker” support system to reduce shock load by preventing link lock-out.

Nested Nylatrac® Modular TL carriers operate fully submerged at an entertainment attraction. These carriers are designed for rotational and long travel in a side-mounted configuration.