What are Cable Carrier Drag Chains?

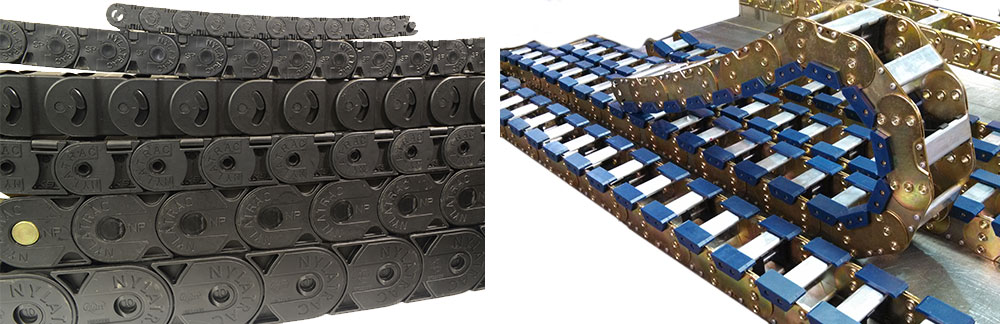

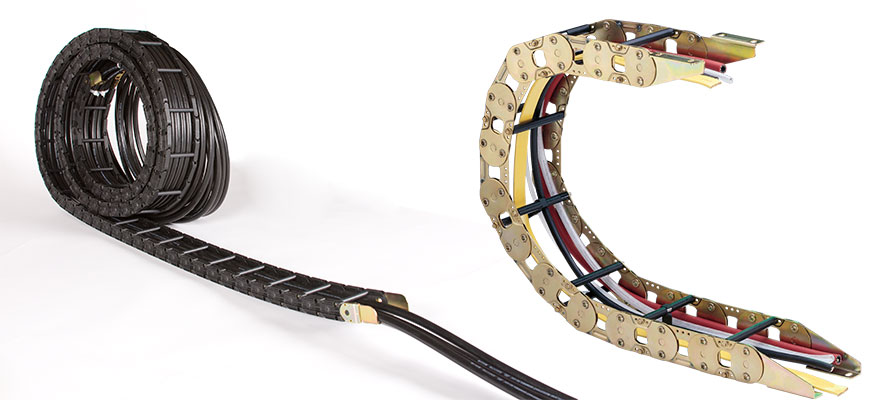

Drag chains, also known as cable carriers, cable tracks, or energy chains, are essential protective components for cables and hoses, ensuring smooth operation and preventing costly downtime. A drag chain is made up of several linked plastic or metal side bands (or side plates) connected by cross bars or plates that form an individual link. This allows the chain to bend through a curve as one end moves along a fixed track. By guiding, organizing, and supporting cables and hoses, drag chains prevent entanglement, snagging, and damage: critical factors for maintaining machine performance and safety, especially for pressurized hoses. Interior dividers can be incorporated into some drag chains to further organize and protect smaller cables from larger ones.

Terminology: Drag Chains vs. Cable Carriers vs. Cable Tracks

One theory about the origin of these terms – drag chains, cable carriers, and cable tracks – relates to their function. The term “drag chain” likely comes from the dragging motion of a chain alongside larger machines, but with automated machinery this is more of a carrying motion, consequently the alternative term: “carrier”. The earliest applications of drag chains may have involved straightforward, open designs where the chain literally dragged on a fixed surface.

Alternative names for drag chains such as cable carrier, cable chain, energy chain, or cable track, support the idea of providing a path or guidance for the cables.

Which term is correct? Dynatect believes they all adequately describe the function of protecting and guiding hoses in automated machinery. In some industries, drag chain might be the most common term due to tradition, however Dynatect uses the term “cable carrier” in its catalog for its clear and descriptive nature.

Why are Drag Chains Important in Industrial Settings?

In industrial settings, drag chains are crucial for several reasons that impact safety, efficiency, and overall operations. Unmanaged or loose cables create tripping hazards and risk snagging on moving machinery, posing threats to both workers and equipment.

Organized cables and hoses with proper strain relief help minimize these risks. Additionally, proper cable management saves time during maintenance and troubleshooting by allowing for quick identification of cables. Conversely, a chaotic mess of tangled cables can waste valuable time during repairs.

Constant strain and friction can wear down unprotected cables, reducing their lifespan and requiring costly replacements. Drag chains help keep cables secure and reduce stress and strain.

Functions of Cable Carrier Drag Chains: How They Work

A drag chain consists of interconnected plastic or metal links that create a sealed or partly enclosed pathway, offering a protected structure for cables and hoses to travel within. Like how a spine protects vital nerves in the body, a drag chain functions as a protective spine for vital cables and hoses in a machine, allowing for flexible movement, guidance, and support.

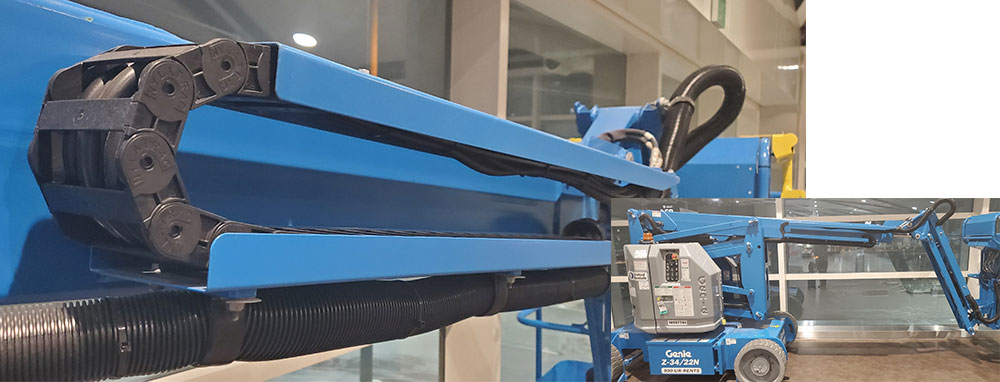

One end of the drag chain is fixed to a static part of the machine, while the other end connects to the moving element. As the machine operates, the drag chain moves along a designated track, guiding the cables and hoses through its channel. During operation, the linked structure of the drag chain keeps the cables and hoses organized and ensures they stay within a designated path. Preventing loose cables from twisting or whipping around keeps them from snagging on other parts of the machinery. An enclosed design can shield the contents from process generated hazards which may include dust, debris, and hot metal chips.

Where are Drag Chains Used?

Drag chains are used in any industrial sector where cable management is crucial. Beyond CNC machines in manufacturing plants, here are some examples where drag chains provide guidance and protection:

- Automation and robotics (check out our industry pages to see more examples)

- Automated material handling systems

- Gantry cranes

- Printing machinery

- Food and beverage processing equipment

- Oil & gas industry – Read more about customized steel drag chains for onshore and offshore applications

Conclusion

Cable carrier drag chains are a vital component for guiding and protecting hoses and cables in dynamic applications. Regardless of your industry, they can provide a variety of benefits such as extended cable lifespan, improved safety, and maximum uptime. At Dynatect, we are committed to innovation in drag chain technology, ensuring our cable carriers continue to meet the evolving demands of modern automated machinery. Contact Dynatect today to discuss your specific needs.