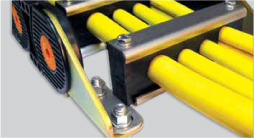

Rail Clamping System

Overview

- Can be integrated into most carriers

- Quick installation

- Stackable design provides space efficiency

- Available for 1, 2, or 3 stacked cable configurations

- Custom spacers can be designed to accommodate cables/hoses too small for clamp range

- Clamp material: hot-dipped galvanized steel (stainless steel available upon request)

Clamp Specs

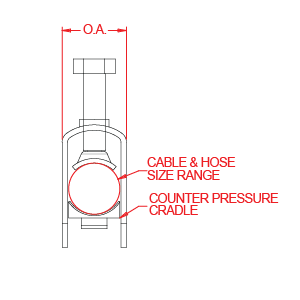

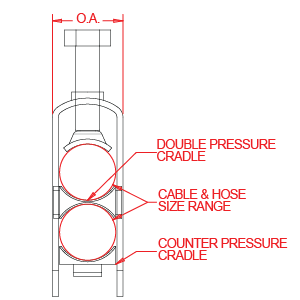

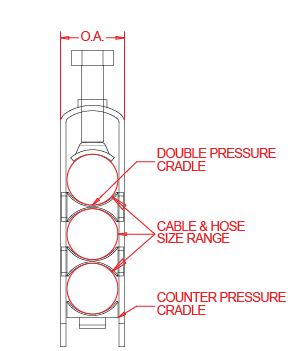

Note: Counter pressure cradles are supplied with all clamps. When clamp rail specified, length is determined by cable carrier width, number of cable clamps and/or customer-specified space requirements.

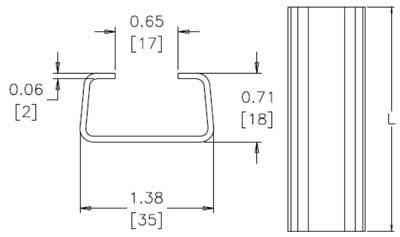

Clamp Rail

Part Number: PN0348483

Single Stack Clamps

| Diameter Range | Overall Width (OA) | Part No. |

| 0.31 (8) – 0.47 (12) | 0.63 (16) | PN0348422 |

| 0.47 (12) – 0.63 (16) | 0.79 (20) | PN0348423 |

| 0.63 (16) – 0.87 (22) | 1.06 (27) | PN0348424 |

| 0.87 (22) – 1.10 (28) | 1.30 (33) | PN0348425 |

| 1.10 (28) – 1.34 (34) | 1.54 (39) | PN0348426 |

| 1.34 (34) – 1.57 (40) | 1.77 (45) | PN0348427 |

| 1.57 (40) – 1.81 (46) | 2.01 (51) | PN0348428 |

| 1.81 (46) – 2.05 (52) | 2.24 (57) | PN0348429 |

| 2.05 (52) – 2.28 (58) | 2.52 (64) | PN0348430 |

| 2.28 (58) – 2.52 (64) | 2.76 (70) | PN0348431 |

| 2.52 (64) – 2.76 (70) | 2.99 (76) | PN0348432 |

| 2.76 (70) – 2.99 (76) | 3.23 (82) | PN0348433 |

| 2.99 (76) – 3.23 (82) | 3.46 (88) | PN0348434 |

| 3.23 (82) – 3.54 (90) | 3.82 (97) | PN0348435 |

| 3.54 (90) – 3.94 (100) | 4.21 (107) | PN0348436 |

Double Stack

| Diameter Range | Overall Width (OA) | Part No. |

| 0.31 (8) – 0.47 (12) | 0.63 (16) | PN0348437 |

| 0.47 (12) – 0.63 (16) | 0.79 (20) | PN0348438 |

| 0.63 (16) – 0.87 (22) | 1.06 (27) | PN0348439 |

| 0.87 (22) – 1.10 (28) | 1.30 (33) | PN0348440 |

| 1.10 (28) – 1.34 (34) | 1.54 (39) | PN0348441 |

| 1.34 (34) – 1.57 (40) | 1.77 (45) | PN0348442 |

| 1.57 (40) – 1.81 (46) | 2.01 (51) | PN0348443 |

| 1.81 (46) – 2.05 (52) | 2.24 (57) | PN0348444 |

| 2.05 (52) – 2.28 (58) | 2.52 (64) | PN0348445 |

| 2.28 (58) – 2.52 (64) | 2.76 (70) | PN0348446 |

Triple Stack

| Diameter Range | Overall Width (OA) | Part No. |

| 0.31 (8) – 0.47 (12) | 0.63 (16) | PN0348447 |

| 0.47 (12) – 0.63 (16) | 0.79 (20) | PN0348448 |

| 0.63 (16) – 0.87 (22) | 1.06 (27) | PN0348449 |

| 0.87 (22) – 1.10 (28) | 1.30 (33) | PN0348450 |

| 1.10 (28) – 1.34 (34) | 1.54 (39) | PN0348451 |

| 1.34 (34) – 1.57 (40) | 1.77 (45) | PN0348452 |

| 1.57 (40) – 1.81 (46) | 2.01 (51) | PN0348453 |

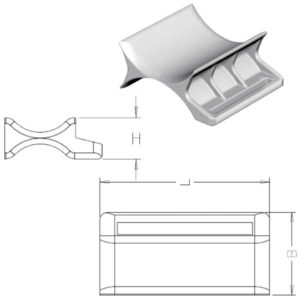

Counter Pressure Cradles

Counter Pressure Cradle

| Diameter Range | Part No |

| 0.31 (8) – 0.47 (12) | PN0348454 |

| 0.47 (12) – 0.63 (16) | PN0348455 |

| 0.63 (16) – 0.87 (22) | PN0348456 |

| 0.87 (22) – 1.10 (28) | PN0348457 |

| 1.10 (28) – 1.34 (34) | PN0348458 |

| 1.34 (34) – 1.57 (40) | PN0348459 |

| 1.57 (40) – 1.81 (46) | PN0348460 |

| 1.81 (46) – 2.05 (52) | PN0348461 |

| 2.05 (52) – 2.28 (58) | PN0348462 |

| 2.28 (58) – 2.52 (64) | PN0348463 |

| 2.52 (64) – 2.76 (70) | PN0348464 |

| 2.76 (70) – 2.99 (76) | PN0348466 |

| 2.99 (76) – 3.23 (82) | PN0348467 |

| 3.23 (82) – 3.54 (90) | PN0348468 |

| 3.54 (90) – 3.94 (100) | PN0348469 |

Double Counter Pressure Cradle

| Diameter Range | Part No |

| 0.31 (8) – 0.47 (12) | PN0348474 |

| 0.47 (12) – 0.63 (16) | PN0348475 |

| 0.63 (16) – 0.87 (22) | PN0348476 |

| 0.87 (22) – 1.10 (28) | PN0348477 |

| 1.10 (28) – 1.34 (34) | PN0348478 |

| 1.34 (34) – 1.57 (40) | PN0348479 |

| 1.57 (40) – 1.81 (46) | PN0348480 |

| 1.81 (46) – 2.05 (52) | PN0348481 |

| 2.05 (52) – 2.28 (58) | PN0348482 |

More Clamping Options

Custom UHMW Clamps

- Can be integrated into most carriers

- Quick installation

Integrated Strain Relief Mounting Brackets

- Optional on most cable carriers

- Cables secured to tabs using zip ties

Zip Tie Bar

- Zip tie bars integrated into mounting brackets

- Tiered structure for easy access

- Double rows of large fingers hold more zip ties

- Anti-slip ridges on bar prevent cable slippage