1. Vehicle Weight Impact on EV Range

RUD are lighter than factory swing doors. Dynatect’s aluminum slats are formed with a hollow core, the industry’s thinnest walls resulting in the lowest weight-to-rigidity ratio for reliable performance and optimized EV range.

2. Reduce Lighting Demand for EV

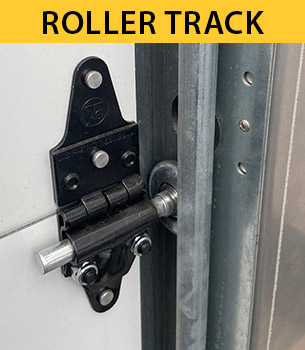

Many delivery vehicles include translucent ceilings in the cargo area to minimize the need for electric lighting. When these vehicles are combined with traditional “garage doors” that run the length of the ceiling, electric lights are needed to compensate for the obscured sunlight. Dynatect’s compact door roller eliminates overhead interference, maximizing sunlight, and minimizing the need for supplemental light. This reduced electrical usage has added benefits of providing more reliable EV range.

3. Noise Reduction

Dynatect’s aluminum slat roll-up doors are significantly quieter than traditional roll-back doors, up to 60% less noise output. See the section named “Door Rattle” under Challenges with traditional roll-back (garage-style) doors to learn how Dynatect’s doors are brake/squeak/rattle (BSR) compliant for quiet operation.

4. Battery System Integration

Automation for roll-up doors can include electric latches, locks, and motorized open/close. Dynatect has the experience to know that low current consumption and signal duration are critical considerations that we can collaborate to solve. The automation and power door system can be integrated directly within the vehicle’s electrical infrastructure.

1. Automation Efficiency

RUD can be automated for open/close – swing-out doors cannot. As such, RUD improves efficiencies of high cycle delivery services. The operators can use automation to have the open/close function initiate while they are approaching or departing the vehicle, saving time and repetitive stress.

2. Loading Dock Safety and Efficiency

For delivery vehicles that may have mixed destinations, including loading docks, traditional swing-out doors create challenges. The driver must back up near a dock, then open the swing-out doors, then back up to the dock (without damaging the doors) – and all the same steps before leaving. In contrast, roll-up doors eliminate multiple stops/starts and the vehicle can be backed up once to the dock with full usability to open and close the door.

3. Safety on Slopes

Swing-out doors can fight the operator when the vehicle is parked on steep slopes. Under these conditions, gravity makes the doors less controllable when opening, or not staying open, depending on which direction of the vehicle is parked. In contrast, Dynatect’s roll-up door changes the direction of door motion and is spring tensioned to provide consistent performance regardless of how the vehicle is parked on a slope. The roll-up door will not accidentally move in response to parking on steeply sloped streets.

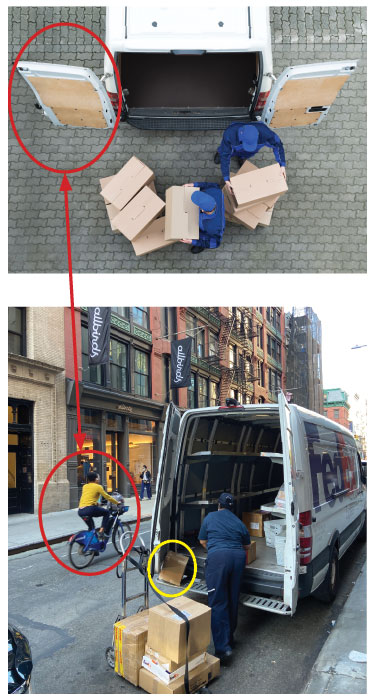

4. Impact Safety

Swing-out doors create impact hazards in the presence of traffic, bicycles, pedestrians, street signs, and trees. They create an additional challenge of forcing operators to walk around the door in the presence of these hazards. Any incidental impact from backing up is absorbed by the bumper rather than a swing-out door. If there is incidental damage, individual slats can be replaced instead of the whole swing-out door.

5. Improved Ergonomics

RUD help reduce risk of injury and fatigue with convenient access doors that roll open. RUD spring roller technology includes calibrated tension that ergonomically balance the door for least effort opening and closing force. Each door also features a pull strap to accommodate closing while the operator is standing on the ground, regardless of truck height. RUD can also be automated for open/close.

6. Improved Fuel Efficiency

RUD are lighter than factory swing doors. Dynatect’s aluminum slats are formed with a hollow core, the industry’s thinnest walls resulting in the lowest weight-to-rigidity ratio. This reduced weight has added benefits of providing more fuel efficiency and more reliable EV range.

Ten Challenges with Traditional Roll-Back (garage) Doors Improved by Thin-Slatted Roll-Up Doors (RUD)

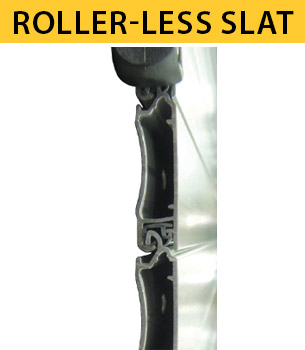

1. Door Rattle

As delivery vehicles move to near-silent-electric, the remaining noise is the thunderous repetitive rattle of the rear roll-back door. Listen to examples here [YouTube Link].

Solution: Dynatect has revolutionized door noise by eliminating traditional rollers which rattle in all dimensions. Further, the slats are held captive in the rails with rubber seals, preventing rattle due to front/back forces. Finally, Dynatect’s doors feature spring loaded tension pulling the slats apart and engaging a plastic barrier between each of the slats, preventing rattle due to up/down forces.

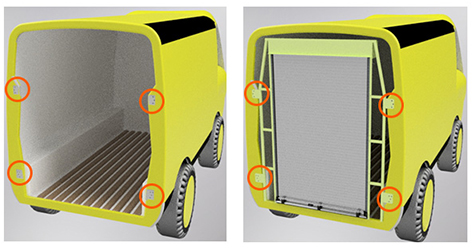

2. Longer Install

Traditional roll-back doors…

- Require separate installation of each rail and the door (multiple alignment points)

- Require installation from inside the truck

Solution: Dynatect has revolutionized the installation of roll up doors that reduces installation time, labor, and cost. Dynatect now offers a bolt-in installation designs that include the rails, slatted doors, and just four vehicle connection points. This design can support under one-minute installation in high-volume OEM environments and allows for field/depot replacement with minimal time/tools required. (As pictured above)

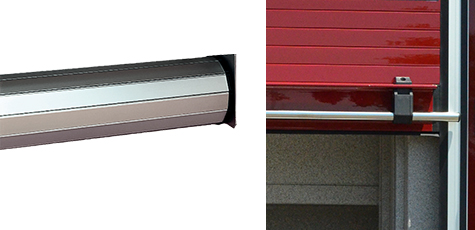

3. Overhead Interference

Roll-back doors create overhead interference for operators, top shelf access, tall cargo, and side-door access.

4. Weather

Roll-back doors bring the snow and rain directly over the cargo area to drip onto packages and operators.

In contrast, Dynatect’s water management features include bottom door seals and a roller canister that captures the entire door in a confined area (drip pan also available):

5. Blockage

Roll-back doors block the top of the cargo area when fully open, impeding efficiency improvements like translucent ceilings.

Solution: Dynatect’s small slat height allows the door to be fully contained in a small rolled up space, consuming minimal overhead while maximizing opening height, operator room and cargo space. (see below)

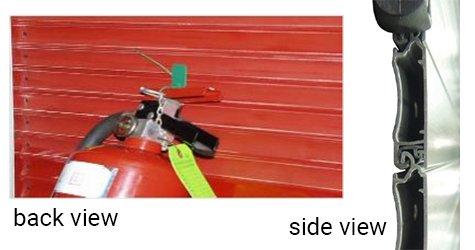

6. Package Shifting

Roll-back doors have cargo-side panel hinges which are vulnerable to package shifting which prevent the door from opening and/or damage the packages.

Solution: Dynatect’s aluminum door slat has a concave back to help prevent objects from jamming the door. (as pictured below)

7. Open Door

Roll-back doors have simple spring mechanisms that result in variability for door remaining in a partially open position. Partially open large panel doors can fall down and may cause injury or damage to cargo.

Solution: Dynatect’s spring roller technology includes calibrated tension that ergonomically balance the door for least effort opening and closing force. (as pictured below)

8. Pinch Points

Roll-back doors have large panels that create pinch points.

Solution: Dynatect’s roll up doors feature slats that are 1-3/8” tall and closely coupled together which eliminates the pinch points of a traditional paneled roll up door. (as pictured below)

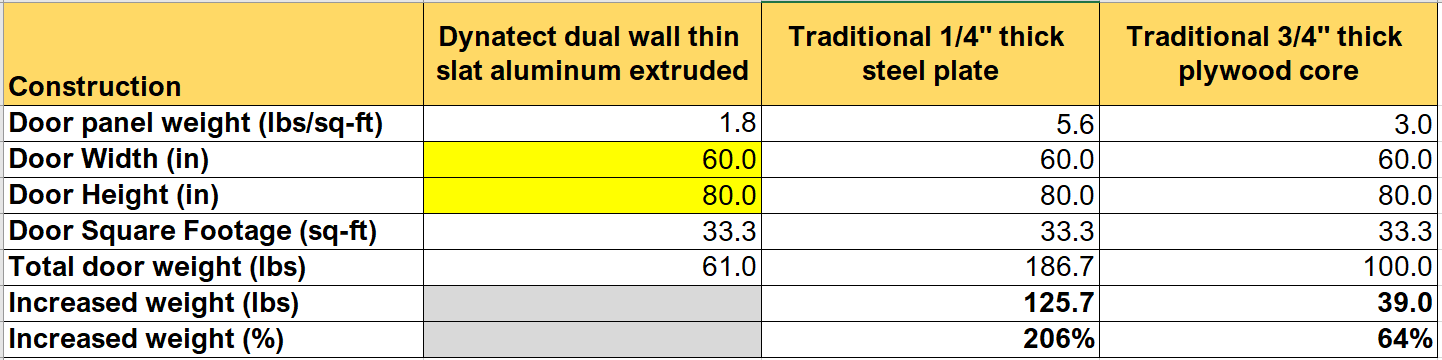

9. Weight

Roll-back doors have thick panels that are 60-100% heavier than thin-slat doors.

Solution: Dynatect’s aluminum slats are formed hollow core, with the industry’s thinnest walls resulting in the lowest weight-to-rigidity ratio. This reduced weight has the added benefit of providing more fuel efficiency and more reliable EV range.

Find out how much less your door could weigh with this calculator:

*This is inclusive of door panels and all door mounting hardware (operator, springs, hinges, rails, header, etc)

10. Door Life

Roll-back doors have metal-on-metal roller contact that adds to NVH and BSR and reduce total door life.