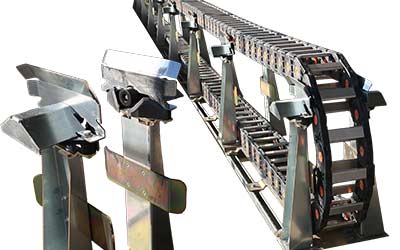

Articulating Roller Support (ARS) Long Travel System

Articulating Roller Support (ARS) Long Travel System

A Long Travel Solution for Plastic Carriers that Eliminates Guide Troughs

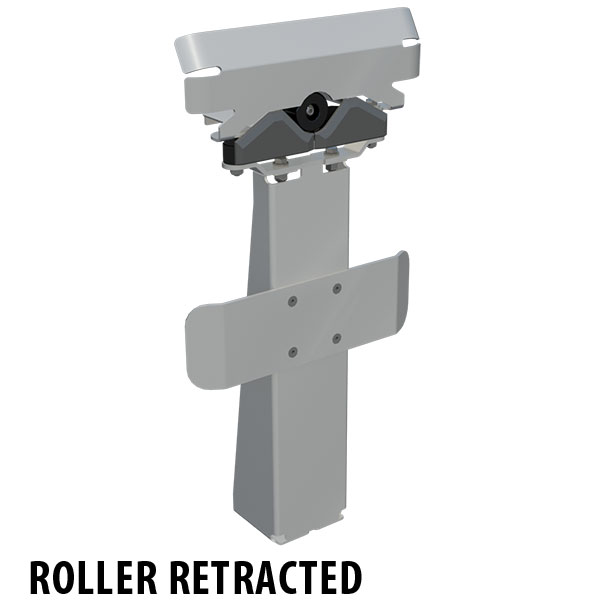

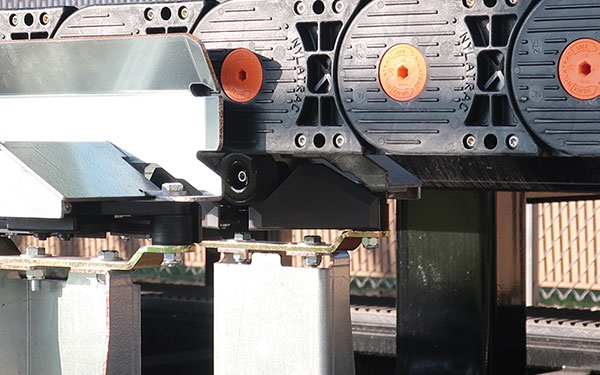

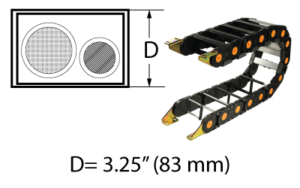

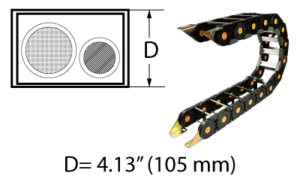

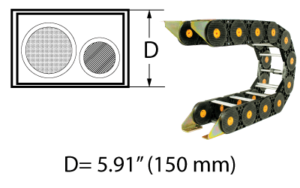

Dynatect’s patented ARS Long Travel Support System is the evolution of 50 years of experience. Its unique, patented design adds articulating rollers that are positioned to support a standard plastic carrier and provide travels up to 300 feet without a guide trough. Dynatect’s long travel cable carriers are ideal for many applications including robot transfer units, large machining centers, gantry robots, plasma and flame cutters, CNC drilling, automated welding, CNC burn tables, transfer systems, and gantry cranes.