Sewn Bellows

Custom Sewn Bellows

Sewn bellows help keep abrasive grit, impinging chips, and coolant off of machine ways and ball screws. Sewn bellows boots are ideal for protecting hydraulic cylinder rods, shafts and splines. Using a bellows cover is essential for mitigating damage to actuators and motion components, thus maintaining uptime.

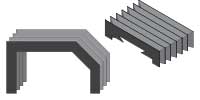

Typical Shapes:

- Flat / Way Cover

- Round

- Rectangular / Square

Typical Applications:

- Machine bellows: way covers and linear rail protection

- Cylinder boots: hydraulic cylinder protection

- Screw or spindle protection; ball screw cover, acme or lead screw cover

- Dust covers: protection for robotic arms or commercial equipment

- Bellows boots: protection for shifts and joysticks

- Lift table skirting: protection around base of scissors lift mechanism

Materials:

- Aluminized Fiberglass

- Nitrile/Nylon

- Goralon® (CSM)/Nylon

- Goralon® (CSM)/Polyester

- Chloroprene/Nylon

- Silicone/Fiberglass

- PTFE/Fiberglass

- Specialty: Ask Dynatect about expanded temperature ranges, chemical resistance, or flame retardant requirements

Accessories:

- Zipper (for installation)

- Tie-strips (to limit cover stretch)

- Grommets (For use with supports or guide rods)

- Internal guides/inserts (for use with rotating shafts/ball screws)

- Mounting clamps (for collar ends)

- Back-up plates (mounting support for flange ends)

Literature, Downloads, Quote Request Forms

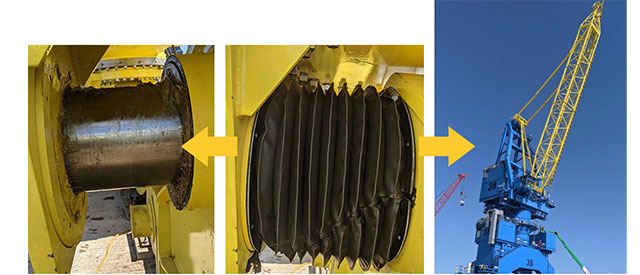

Protective Bellows for Hydraulic Cylinders

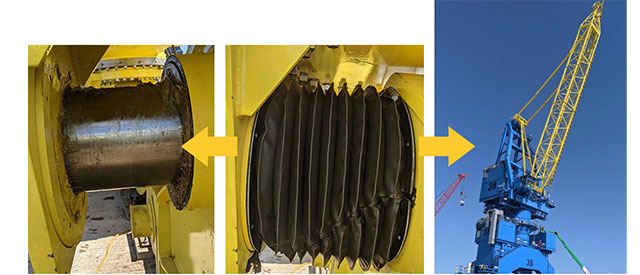

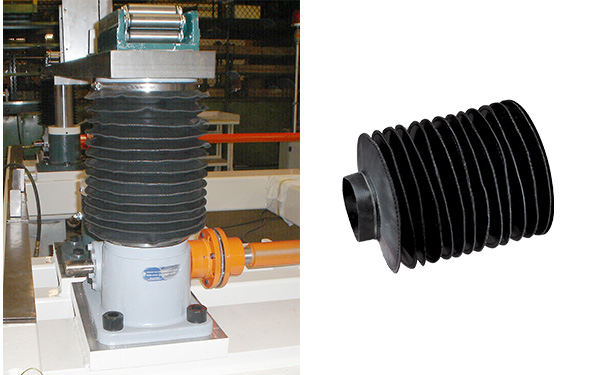

Large crane rigs often feature hydraulic cylinders, which are required to operate with long service life between maintenance and inspection periods.

- The original bellows in this application were not lasting due to sagging.

- Dynatect was brought in to engineer a better bellows design which included stiffer neoprene nylon, a better extended to retracted ratio, and easier installation.

- Dynatect provided a durable sewn bellows designed to withstand outdoor conditions and heavy grease lubricant from within.

- The zipper feature is essential for installation and future access.

Advantages of Cylinder Boots

- Reduce frequency of shaft seal replacements

- Prevent rod scoring

- Eliminate nicking of shafts and ball screws

- Protect against impinging chips

- Guard against grit abrasion

- Shield from corrosive splatter

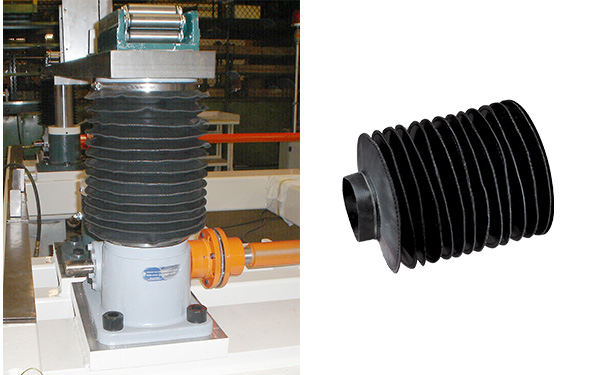

More Sewn Bellows Applications

The bellows shown below is “4 stories” tall (drilling equipment)

Sewn bellows used for shaft protection:

Bellows used for screw protection:

Rod Boots

Rod Boots

Common Sizes & Legacy Part Numbers

Here are the legacy part numbers representing common rod boot sizes of Gortite® Sewn Bellows made from neoprene-coated nylon fabric.

| ROD BOOT STYLE |

Inside Diameter (ID) |

Outside Diameter (OD) |

Retracted Length every 12″ section |

Available Inner Diameter (I.D.) Sizes |

| SRA-15 |

3/4″ |

3″ |

3/4″ |

1/2″ to 3″ |

| SRB-15 |

1-1/8″ |

3-3/8″ |

3/4″ |

1/2″ to 3-3/8″ |

| SRC-15 |

1-1/2″ |

3-3/4″ |

3/4″ |

1/2″ to 3-3/4″ |

| SRD-15 |

1-7/8″ |

4-1/8″ |

3/4″ |

1/2″ to 4-1/8″ |

| SRE-15 |

2-3/8″ |

4-5/8″ |

3/4″ |

1/2″ to 4-5/8″ |

| SRF-15 |

2-7/8″ |

5-1/8″ |

3/4″ |

1/2″ to 5-1/8″ |

| SRG-25 |

3-3/8″ |

7″ |

1/2″ |

1/2″ to 7″ |

| SRH-25 |

3-7/8″ |

7-1/2″ |

1/2″ |

1/2″ to 7-1/2″ |

| SRJ-25 |

4-1/2″ |

8-1/4″ |

1/2″ |

1/2″ to 8-1/4″ |

| SRK-25 |

5″ |

8-3/8″ |

1/2″ |

1/2″ to 8-3/8″ |

| SRM-25 |

5-3/8″ |

9-1/2″ |

1/2″ |

1/2″ to 9-1/2″ |

| SRO-25 |

7-1/4″ |

11″ |

1/2″ |

1/2″ to 11″ |

Mounting Accessories: Clamps (for end collars) or Back-up mounting plates (for flange ends) can be added to your order upon request

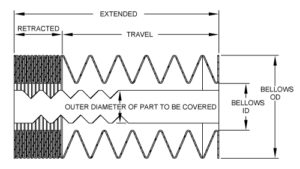

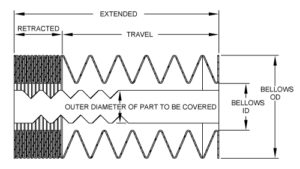

How to Request a Quote for Standard Size Shown Above

Sewn Rod Boot Bellows Request for Quote

1. Stock boot part number

2. Outer diameter (O.D.) of part to be covered

3. Travel distance or extended length (note: ends excluded) Stock bellows are available in 12″ extended length increments

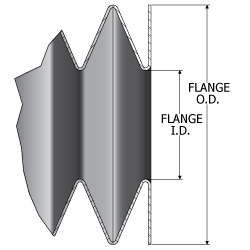

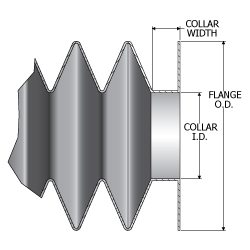

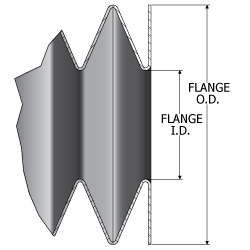

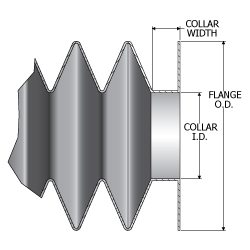

4. Specify type of end: Do you want a standard flange or a collar?

For Collar End: Specify collar width and collar I.D. (inner diameter)

For Flange End: Specify Flange I.D. (inner diameter) and Flange O.D. (outer diameter)

5. Specify mounting options:

a. C208 Clamp: stocked in any size required, clamp band is 1/2” wide, minimum 1/2” I.D. – specify in 1/8” increments.

b. C205 flange back-up plate: shipped blank. If mounting holes are desired, please send sketch indicating bolt hole pattern and size.