Design Specs - English

How To Create A Part Number:

Model – Height – Length – Bracket (fixed) – Bracket (moving)

Example: N4-10-31.52-Type A-Type A

⇒ Length is specified in inches, to two decimals. It is the distance between flanges

⇒ (see formula on carrier side view diagram)

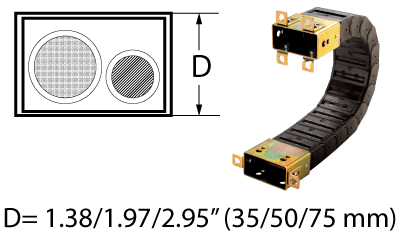

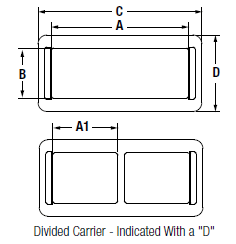

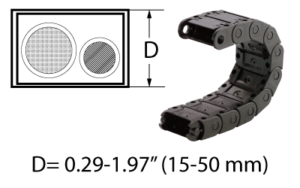

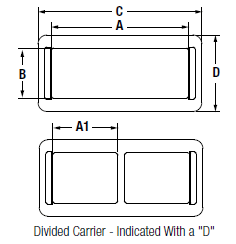

Cross Section View

| MODEL |

A (inner width) |

A1 (divided width) |

B (inner height) |

C (outer width) |

D (outer height) |

Weight (lb/ft) |

| N1 |

0.90 |

— |

0.90 |

1.38 |

1.38 |

0.50 |

| N2 |

1.50 |

— |

0.90 |

1.97 |

1.38 |

0.60 |

| N3-D* |

2.48 |

1.18 |

0.90 |

2.95 |

1.38 |

0.80 |

| N4 |

1.42 |

— |

1.34 |

1.97 |

1.97 |

0.80 |

| N5 |

3.39 |

— |

1.34 |

3.94 |

1.97 |

1.20 |

| N5-D* |

3.39 |

1.63 |

1.34 |

3.94 |

1.97 |

1.20 |

| N6-D* |

5.35 |

2.62 |

1.34 |

5.91 |

1.97 |

1.70 |

| N8 |

5.28 |

— |

2.24 |

5.91 |

2.95 |

2.20 |

*Divided cavity

Specifications are listed as inches unless otherwise noted

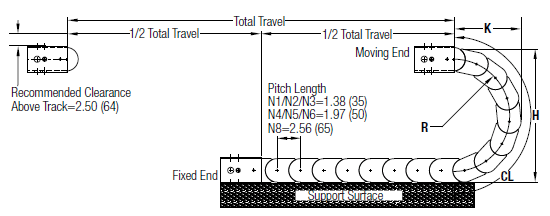

Carrier Side View inches (mm)

Travel/2 + CL (+ Offset Distance From Center*) = Length

Dynatect recommends mounting the stationary end of the carrier at the center of travel, minimizing the required length.

In cases where center mounting is not possible, add the distance offset from center to the carrier length calculation.

| Height |

R (bend radius) |

H (curve height) |

K (depot) |

CL (curve length) |

| N1 – 8 |

3.30 |

8.00 |

5.40 |

13.20 |

| N1 – 13 |

5.91 |

13.20 |

8.00 |

21.30 |

| N2 – 8 |

3.30 |

8.00 |

5.40 |

13.20 |

| N2 – 13 |

5.91 |

13.20 |

8.00 |

21.30 |

| N3 – 8D* |

3.30 |

8.00 |

5.40 |

13.20 |

| N3 – 13D* |

5.91 |

13.20 |

8.00 |

21.30 |

| N4 – 10 |

3.94 |

9.80 |

7.00 |

16.30 |

| N4 – 18 |

7.87 |

17.70 |

10.70 |

28.70 |

| N5 – 10 |

3.94 |

9.80 |

7.00 |

16.30 |

| N5 – 10D* |

3.94 |

9.80 |

7.00 |

16.30 |

| N5 – 18 |

7.87 |

17.70 |

10.70 |

28.70 |

| N5 – 18D* |

7.87 |

17.70 |

10.70 |

28.70 |

| N6 – 10D* |

3.94 |

9.80 |

7.00 |

16.30 |

| N6 – 18D* |

7.87 |

17.70 |

10.70 |

28.70 |

| N8 – 15 |

5.91 |

14.80 |

10.00 |

23.70 |

| N8 – 27 |

11.81 |

26.60 |

15.90 |

42.20 |

Specifications are listed as inches unless otherwise noted

Design Specs - Metric

How To Create A Part Number:

Model – Height – Length – Bracket (fixed) – Bracket (moving)

Example: N4-10-31.52-Type A-Type A

⇒ Length is specified in inches, to two decimals. It is the distance between flanges

⇒ (see formula on carrier side view diagram)

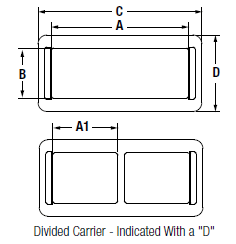

Cross Section View

| MODEL |

A (inner width) |

A1 (divided width) |

B (inner height) |

C (outer width) |

D (outer height) |

Weight (kg/m) |

| N1 |

23 |

— |

23 |

35 |

35 |

0.74 |

| N2 |

38 |

— |

23 |

50 |

35 |

0.89 |

| N3-D* |

63 |

30 |

23 |

75 |

35 |

1.19 |

| N4 |

36 |

— |

34 |

50 |

50 |

1.19 |

| N5 |

86 |

— |

34 |

100 |

50 |

1.79 |

| N5-D* |

86 |

41 |

34 |

100 |

50 |

1.79 |

| N6-D* |

136 |

67 |

34 |

150 |

50 |

2.53 |

| N8 |

134 |

— |

57 |

150 |

75 |

3.27 |

*Divided cavity

Specifications are listed as millimeters unless otherwise noted

Carrier Side View inches (mm)

Travel/2 + CL (+ Offset Distance From Center*) = Length

Dynatect recommends mounting the stationary end of the carrier at the center of travel, minimizing the required length.

In cases where center mounting is not possible, add the distance offset from center to the carrier length calculation.

| Height |

R (bend radius) |

H (curve height) |

K (depot) |

CL (curve length) |

| N1 – 8 |

84 |

203 |

137 |

335 |

| N1 – 13 |

150 |

335 |

203 |

541 |

| N2 – 8 |

84 |

203 |

137 |

335 |

| N2 – 13 |

150 |

335 |

203 |

541 |

| N3 – 8D* |

84 |

203 |

137 |

335 |

| N3 – 13D* |

150 |

335 |

203 |

541 |

| N4 – 10 |

100 |

249 |

178 |

414 |

| N4 – 18 |

200 |

450 |

272 |

729 |

| N5 – 10 |

100 |

249 |

178 |

414 |

| N5 – 10D* |

100 |

249 |

178 |

414 |

| N5 – 18 |

200 |

450 |

272 |

729 |

| N5 – 18D* |

200 |

450 |

272 |

729 |

| N6 – 10D* |

100 |

249 |

178 |

414 |

| N6 – 18D* |

200 |

450 |

272 |

729 |

| N8 – 15 |

150 |

376 |

254 |

602 |

| N8 – 27 |

300 |

676 |

404 |

1072 |

Specifications are listed as millimeters unless otherwise noted

Mounting Flange

Table dimensions are inches (mm)

| Flange Type |

C1 |

D1 |

Q |

T |

S |

| Standard / N1 |

1.59 (40) |

1.54 (39) |

1 hole |

— |

— |

| Standard / N2 |

2.13 (54) |

1.54 (39) |

0.79 (20) |

— |

— |

| Standard / N3 |

3.11 (79) |

1.54 (39) |

1.77 (45) |

— |

— |

| Standard / N4 |

2.13 (54) |

2.13 (54) |

0.79 (20) |

— |

— |

| Standard / N5 |

4.09 (104) |

2.13 (54) |

2.76 (70) |

— |

— |

| Standard / N6 |

6.06 (154) |

2.13 (54) |

4.72 (120) |

— |

— |

| Standard / N8 |

6.06 (154) |

3.11 (79) |

4.72 (120) |

— |

— |

| Type A / N1 |

1.59 (40) |

1.54 (39) |

1 hole |

2.49 (63) |

3.18 (81) |

| Type A / N2 |

2.13 (54) |

1.54 (39) |

0.79 (20) |

2.49 (63) |

3.18 (81) |

| Type A / N3 |

3.11 (79) |

1.54 (39) |

1.77 (45) |

2.49 (63) |

3.18 (81) |

| Type A / N4 |

2.13 (54) |

2.13 (54) |

0.79 (20) |

3.09 (79) |

3.78 (96) |

| Type A / N5 |

4.09 (104) |

2.13 (54) |

2.76 (70) |

3.14 (80) |

3.83 (97) |

| Type A / N6 |

6.06 (154) |

2.13 (54) |

4.72 (120) |

3.14 (80) |

3.77 (96) |

| Type A / N8 |

6.06 (154) |

3.11 (79) |

4.72 (120) |

4.07 (103) |

4.76 (121) |

| Type B / N1 |

1.59 (40) |

1.54 (39) |

2.49 (63) |

— |

3.18 (81) |

| Type B / N2 |

2.13 (54) |

1.54 (39) |

3.12 (79) |

— |

3.81 (97) |

| Type B / N3 |

3.11 (79) |

1.54 (39) |

4.14 (105) |

— |

4.83 (123) |

| Type B / N4 |

2.13 (54) |

2.13 (54) |

3.09 (78) |

— |

3.78 (96) |

| Type B / N5 |

4.09 (104) |

2.13 (54) |

5.09 (129) |

— |

5.78 (147) |

| Type B / N6 |

6.06 (154) |

2.13 (54) |

7.04 (179) |

— |

7.73 (196) |

| Type B / N8 |

6.06 (154) |

3.11 (79) |

7.05 (179) |

— |

7.71 (196) |