What is Machine Guarding?

Machine guards are safety features, accessories, or systems designed to protect workers from injuries around hazardous equipment. There are various types of machine guards, including fixed, interlocked, adjustable, and self-adjusting. As shields or devices, machine guarding prevents contact with:

- Moving parts (e.g. blades, gears, belts, rotating components)

- Points of operation (areas where materials are processed, like cutting edges or pinch points)

- Flying debris (sparks, chips, or other materials that could be ejected during operation)

Machine guarding can also contribute to better overall workplace safety culture, potentially lower insurance costs, and help comply with legal requirements, which are critical for business operations. For instance, OSHA regulations mandate fall protection for any opening exceeding two inches. (See 1910.28 b for full details) This applies to inspection and machine pits. While guardrails and safety harnesses are options, walk-on duty retractable covers are a more practical solution because they don’t hinder access (guard rails would need to be constantly removed and replaced) nor require complex safety equipment (e.g. overhead anchors and safety harnesses).

Beyond the benefits for preventing injuries, machine guards can also improve productivity by reducing downtime caused by accidents.

Dynatect’s products may be helpful in reducing risks in the following categories:

- Machine Safety Controls

- Fall Protection & Hazardous Openings

- Hands & Arm Protection

- Isolating Pinch Points – Barriers

- Environmental & Fire Protection

(Click on any topic to see specific examples).

Safely Actuating Horizontal Machine Doors

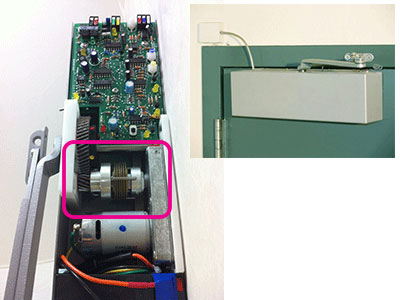

Automatic door actuators, which reverse automatically when objects are detected in their path, are available for retrofitting to existing automatic machining centers with single or double doors. For workers, these help reduce injuries from repetitive door operation (like carpal tunnel syndrome) and crushing incidents.

Dynatect’s SMDA (safe machine door actuator) safely automates horizontal machine doors and has integral safety functions.

The door actuator incorporates a preprogrammed control module allowing several input and output commands. These can be wired into the machine’s controller or a simple on-off circuit; key outputs and messages can also be fed to a controller. Distinct benefits are unlimited travel distances, self-calibration, electric (pneumatic-free) operation, and no need for limit switches, light curtains, pressure switches, or photo eyes. Integrated braking engages at all positions. Some large equipment OEMs report that operators required to open and close safety doors can experience shoulder pain, and door actuators reduces repetitive shoulder injuries by half or more.

Separating Hazardous Processes from People & Equipment

The Gortite VF Automated Machine Safety Door is intended for machine guarding in automated work cells. Typical applications include automated production and machine processes that require preventive measures, such as robotic welding, processing, and transport tasks.

The safety interlock option meets PLE/Cat-4 safety requirements when combined with appropriate logic and conformance to risk assessment.

Additional safety features:

- Door is retained in columns to minimize risk of people falling through closed door (conforms with OSHA guardrail requirements).

- Traveling photo-eye option (bottom edge sensing and reversing) brings the door to an immediate stop.

Covering open pits and other hazardous openings

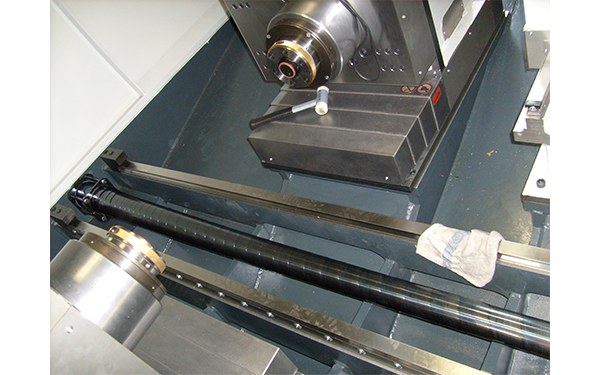

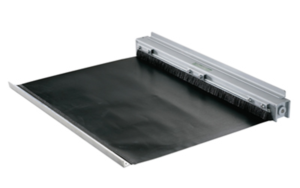

Large machine tools such as planer mills often are installed partially below floor level, resulting in potentially hazardous pits. Often, workers must remove pit grates or slats to service the machine. Here, metal roll-up, walk-on covers offer an alternative. Typically made of reinforced stainless steel, these covers allow partial pit access while preventing falls at other times or into other pit areas.

Dynatect’s walk-on roll-up covers create a continuous, protective, and walk-able surface that makes maintenance easy.

Case in point: One aircraft manufacturer uses large fiber placement machines to build fuselages from composites. Adjustable tailstocks of the two-station machine travel on guideways located in a pit below floor level. Production workers must access workpieces as they’re produced, necessitating pit covers during production, yet also requiring a way to remove the covers for repairs and adjustments. Grating is time-consuming to move, and slats require complex support structures that complicate maintenance tasks. Instead, the aircraft manufacturer uses rugged walk-on metal pit covers with extruded aluminum stiffening ribs bonded to stainless steel sheets; there are no hinges to collect debris. These roll up onto steel rollers equipped with take-up mechanisms.

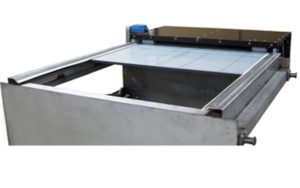

Containing hazardous tank fumes

Roll-up covers can also be used to enclose chemical tanks and other vessels to contain fumes or prevent injury. These covers are not designed to support the weight of workers, so they are made of lighter materials such as polypropylene to withstand corrosive fumes. Wiper strips can keep the cover under tension and remove debris before retraction; electric motors and gear drives are employed in the take-up mechanisms.

Dynatect developed the ChemTank Cover in response to the demand for convenient and space-spacing chemical tank covers. Tank covers help contain evaporative emissions. The ChemTank is a corrosion-resistant roll up cover system that helps control heat and evaporation. It consists of a PVDF-coated PVC shade and compatible hardware for higher corrosive and higher temperature applications. With chemical and surface finishing processes in mind, the cover was designed for a wide variety of process tanks applications including: chemicals, anodizing, etching, plating, cleaning and more.

Safety clutches allow safer interaction with machines

Automated machines may experience unintentional obstructions, such as rotating parts or small access doors driven by a gear mechanism. Dynatect’s mechanical slip clutches have been added to systems to allow safer interaction.

In one such example, a slip clutch is part of a disabled-access system that automates a door’s opening and closing. The slip clutch allows obstructions to the operation without causing injury or damaging the drive motor.

In another application, a slip clutch was integrated into the driveshaft of a food prep machine’s rotating arm to add mechanical safety for the operator.

Scissors and Lift Table Hazards

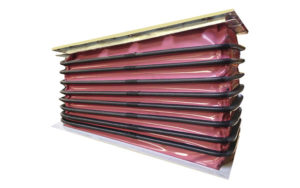

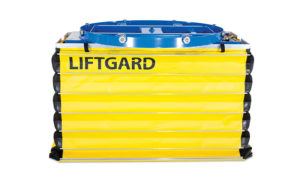

Scissor lift mechanisms, tilt tables, and similar equipment represent potential sources of injury because pinch points can be created when these mechanisms move. One way to protect against these hazards is to enclose moving parts with bellows that deter personnel from reaching into hazardous areas — yet permit machinery motion. Other benefits are improved machinery aesthetics and protection against dust, debris, and foreign objects.

Dynatect makes large-format bellows (“lift covers”) to cover the pinch points of lift tables or scissors mechanisms. In one iteration, heavy-duty accordion-type skirting is made from PVC/nylon and rigid aluminum extrusions with vented corners. The resulting rigid, moveable cover is suitable for lift tables and vertical-motion applications. Vents allow uniform airflow during operation, while optional maintenance straps allow for regular inspection and maintenance of the lift mechanism.

Dynatect makes large-format bellows (“lift covers”) to cover the pinch points of lift tables or scissors mechanisms. In one iteration, heavy-duty accordion-type skirting is made from PVC/nylon and rigid aluminum extrusions with vented corners. The resulting rigid, moveable cover is suitable for lift tables and vertical-motion applications. Vents allow uniform airflow during operation, while optional maintenance straps allow for regular inspection and maintenance of the lift mechanism.

For applications necessitating lateral and linear motion, such as medical table bases, imaging tables, dental chairs, and amusement rides, bellows can be constructed using various materials and internal wires that maintain the necessary shape. Fabrication from a myriad of materials is possible, including some that meet UL burn standards or incorporate antimicrobial agents. Suitable for shear-type or lateral movement, the design’s compactness allows retraction into tight spaces.

Dust Containment

Large CNC machining centers require special effort to minimize the impact of dust and sound on surrounding work areas while still allowing access for loading and unloading large workpieces and tooling. In the examples shown below, a 5-axis machining center incorporates a retractable roof cover over its enclosure to answer both needs.

Do your production processes generate dust or small particles?

Machine roof covers were developed to contain debris and airborne contamination without creating interference or obstructions in the machining center’s travel.

Engine or Motor Ventilation and Ducting

For the ventilation of motors or engines in facilities or transportation applications (locomotives and railcars) rugged, flexible ducting is integral to the solution. Dynatect’s bellows / ducts/ motor-boots can be designed with materials available to meet regulatory compliance for flame, smoke, and toxicity (NFPA 130, EN45545)

Go to Traction Motor Bellows Product Page

Safeguarding Machine Lathes and Other Rotating Parts

Dynatect shade rollers are custom-made protective roll-up covers for machine guarding, consisting of coated or uncoated textile material attached to an industrial spring roller. Metal housing can be added to protect the roll-up mechanism. Shade rollers are a simple and cost-effective solution for involuntary contact with machine components.

Visit Shade Rollers Product Page

Telescopic Springs (aka spiral springs / spring guards) protect against accidents and mechanical damage wherever there are rotating parts, such as a spindle or ball screw on a machine tool.

Visit Telescopic Springs Product Page