Product Details

Dynatect’s Ball Screw Capabilities

Comprehensive Service:

Precision Engineering:

- Precision ground ball screws ensuring high repeatability

- High precision with a lead accuracy of +/- 0.0005”/ft cumulative

Versatile Sizing:

- Ball screw diameter and lead sizes offered in both imperial and metric dimensions

- Diameters available from 5/8″ to 6″ (16 mm – 150 mm)

Unlimited Length:

- No constraints on screw length – our longest to date is an impressive 67 feet

Customization Experts:

- Specialized in customization, reverse engineering, and unique designs

- Capability to convert acme or lead screws to advanced ball screw designs

Facility & Qualifications:

- Certified Quality: ISO 9001:2015 compliant facility

- Extensive Experience: Over 33 years of repairing and manufacturing ball screws

- Modern Facility: Our plant spans 44,649 square feet, located in Traverse City, Michigan

9 Reasons to Choose Dynatect Ball Screws:

Ultimate Design Flexibility and Optimization – Dynatect offers complete options to provide the best balance of price, size, up-time, and performance for an application. Dynatect can now provide twice as many varieties of long lead applications where lead is greater than 50% of the screw diameter.

1) “Zero Lost Motion” Solutions – We customize your design to minimize backlash and eliminate deadband

2) Superior Wiper Technology – Dynatect’s unique wiper design results in a greater wiping surface and better sealing than traditional wipers

3) Best Lead Times in the Industry – We understand the urgency in your operations, and our commitment to prompt delivery sets us apart

4) Easy to work with – Ball screw assemblies can be manufactured based on drawings, a sample unit, or the specifications you provide. Need CAD files? Our fully automated CAD system allows us to design in real-time, so we can deliver a model early in your project.

5) Made to Your Specification – You are not “locked in” to a few ball screw and nut designs in a catalog. We can offer a solution that is easy to install, saving you money by minimizing the need to retrofit or adjust other components.

6) Size Flexibility and Unlimited Selection – Ball screw diameter and lead sizes are offered in both imperial and metric sizes. We manufacture ball screw diameters from 5/8” to 6” and specialize in long screws (the longest to date was 57 feet)

7) High Quality –Ensure the highest quality for your company: Our facility is ISO 9001:2015 certified

8) Full Customization – Your ball screw will be configured with the options you specify, and can be further customized for a complete solution that is quick and easy to install, saving you time and money. Options:

- Ball nut style/configuration (single or double nut, 2-piece flange to flange nut, middle flange nut)

- Internal or external ball returns

- Wipers and end seals

- Custom journal ends

- Custom housing and mounting blocks

Engineered Ball Screw for Precision Motion Applications

Dynatect is a manufacturer of engineered precision ground ball screws designed to meet the demands of precision motion control applications.

The Mechanical Ingenuity of Ball Screws

A ball screw is a mechanical apparatus designed to convert rotational motion into linear motion. The fundamental elements of a ball screw comprise a nut and a screw featuring helical grooves, along with ball bearings. The balls move in a continuous path between the nut, the screw, and the grooves, orchestrated by the rotation of either the screw or the nut. They follow a trajectory within the ball return system of the nut, traversing from the initial point to the endpoint and then returning to the starting position. Wipers are strategically positioned on either side of the nut to act as a protective shield against debris, which can shorten the life of the ball screw assembly.

Applications Requiring High Accuracy

Precision ground ball screws find optimal application where a high degree of travel accuracy is non-negotiable. Travel accuracy is defined as the deviation, represented by the measured lead minus the specified lead. Specifically, within machining operations such as metal cutting and grinding, achieving dimensional tolerances, and ensuring repeatability are critical. Besides machine tools, some ideal applications for precision ball screws include replacing hydraulics on training equipment (convoy training, flight simulators), simulation technologies, and motion platforms.

Not Every Application Requires Precision

Acknowledging the nuanced requisites of diverse engineering applications, not every operational context necessitates the highest precision. In situations where straightforward transport tasks are at hand, and the highest degree of accuracy repeatability is not imperative, the utilization of precision ground ball screws may exceed practical necessity. This is especially relevant in material handling and automated transport lines, where streamlined motion control systems demonstrate effectiveness without compromising performance.

Ball Return Designs

Ball Return Designs

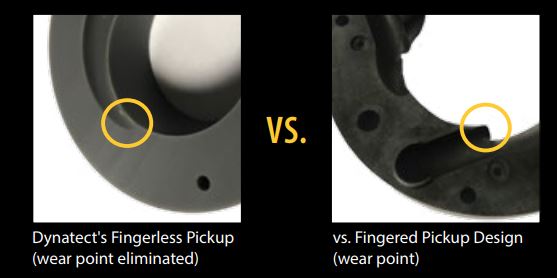

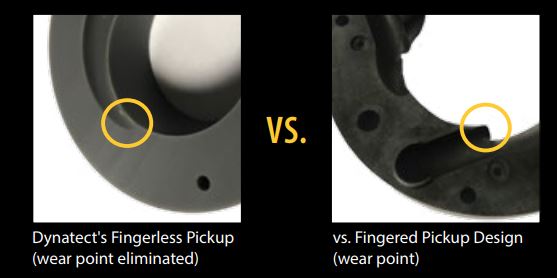

End Cap Return – Single circuit with multiple turns. Best for long lead applications where lead is greater than 50% of the screw diameter. Offers reduced wear thanks to proprietary fingerless pickup design that eliminates the common end-cap wear point and allows for refurbishing.

→ Download Literature (PDF)

→ Download Literature (PDF)

Internal Button Return – Single turn with multiple circuits. Good for typical lead and diameter combinations.

Comparison of Ball Return Designs

| Key Advantage |

Button (internal) |

End Cap (internal) |

Tube (external) |

| Double load capacity / increase life by adding multiple starts while maintaining the same package size |

⊗ No |

Option |

Option |

| Optimal form factor of ball nut |

Most Favorable |

Favorable |

Least favorable |

| Optimal life – balls travel in paths that are tangent to the pitch, resulting in longer life and reduced wear |

Most Favorable |

Favorable |

Least favorable |

| Higher operating speeds – travel path increases permissible speed |

Most Favorable |

Favorable |

Least favorable |

| Smooth operation and low noise – balls spend less time traveling unloaded |

Most Favorable |

Favorable |

Least favorable |

| Ease of installation – components protected by design means low risk of damage during installation |

Most Favorable |

Favorable |

Least favorable |

| Up to 25% Lower cost: Proprietary blind lead on screw results in fewer threads needed for loading nut on ball screw |

✓ Yes |

✓ Yes |

⊗ No |

| Eliminate external tubes which are susceptible to damage, premature wear, speed limitations, noise and increased package size. |

✓ Yes |

✓ Yes |

⊗ No |

End Cap Design

Dynatect can provide twice as many varieties of long lead applications where lead is greater than 50%

of the screw diameter. Dynatect’s diverse capabilities help balance price, size, uptime, and performance for

your application.

Key Features:

- Double load capacity, increase life by adding multiple starts while maintaining the same package size

- Reduced wear: Patented fingerless pickup eliminates the common end-cap wear point and allows for refurbishing

- Up to 25% lower cost: Proprietary blind lead on screw results in fewer threads needed for loading nut on ball screw

- Customizable end cap returns provide application flexibility not found in standard catalog offerings

- Eliminate external tubes which are susceptible to damage, premature wear, speed limitations, noise, and increased package size.

→ Download Literature (PDF)

Repair / Rebuild

Ball Screw Repair & Rebuild

Have you thought about repairing your ball screws? Dynatect can also repair and rebuild your precision ball screw assembly. Assess potential cost savings using our Ball Screw Scenario Savings Calculator.

A rebuild often consists of a screw regrind with a new ball nut. When a ball screw is sent in for repair evaluation, it is sometimes found that the ball screw cannot be reloaded due to pitting, brinneling, and/or damage to interior or exterior of unit. In that case, the unit could be refurbished by manufacturing a new ball nut and regrinding the existing screw to remove pitting and taper. This type of rebuild comes with a warranty.

→ Learn more.