Rubber bellows function as “dust boots” to seal out dust and other light-duty environmental contaminants while enabling a predetermined range of motion for the protected part. Rubber boots are common in industrial and automotive applications. (In automotive applications, the bellows may be called a gaiter. This is a type of bellows that is often used in automotive applications to protect the moving parts of a vehicle’s suspension system from dirt and debris.)

Rubber bellows may function as tubing or ducting, however, bellows are most commonly used as a protective cover.

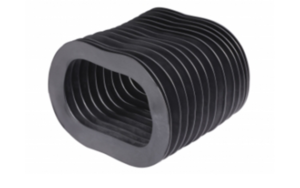

Depending on the manufacturing process, molded bellows can have an extended resting position, which means convolutions are extended in the resting position. For an example, visualize a convoluted drainage pipe. Other bellows may have a “closed” resting position, which means the bellows convolutions are tighter together (naturally compressed) when in a relaxed state.

Many molded rubber bellows tend to have a large extended-to-retracted ratio, and the overall bellows are stiffer.

Dynatect has a variety of manufacturing processes to produce molded bellows in either style. Dynatect’s Gortiflex rubber bellows have an excellent extended-to-retracted ratio, meaning the tight compression can satisfy a more dynamic range of motion.

Molded bellows typically have a more rounded peak at each convolution:

Other rubber (technically elastomer-coated materials) bellows are made by sealing or stitching alternating inner and outer rings of material, resulting in convolutions that are “sharper” or more v-shaped. The latter tends to have a more “industrial” look, although Dynatect’s Thermiseal bellows are exceptionally neat in appearance.

Sometimes bellows are referred to as “convoluted tubing”. Flange and collar options, backup plates, and worm-gear clamps satisfy common mounting requirements. While mounting accessories may be specified at the time of order, it is best to consider the mounting requirements at the time of quote.