Stock Wiper Strips

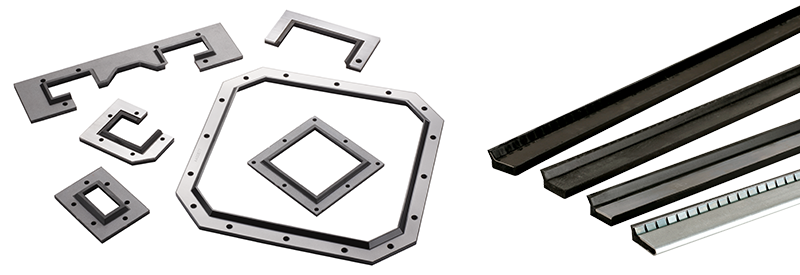

Straight Molded Stock Wipers

Dynatect stock wipers save costly maintenance, reduce downtime, and prolong the service life of machine tool ways. They are molded from abrasion and oil-resistant Buna-N elastomer. Several types of molded wipers are available from stock for fast delivery, without tooling charges.

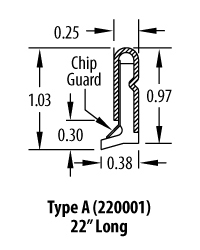

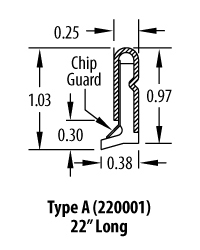

Standard 22″ Length Stock Wipers

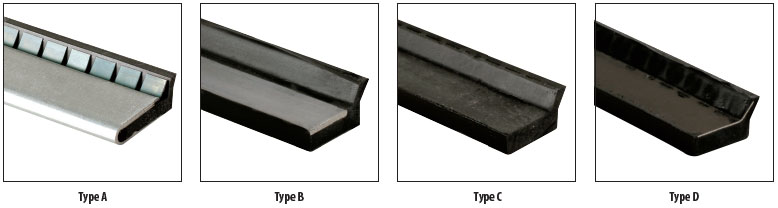

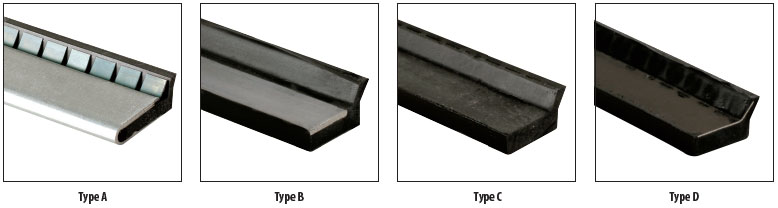

All four types (A, B, C, D) are available in standard 22″ lengths and the wiper material is nitrile. Over sized holes may be drilled in wiper and screws may be used to attach wiper. (Use of over-sized holes makes it easy to adjust the wiper closer to the way for extended service life.)

Download PDF

- Type A (part no. 220001) – Metal enclosed molded nitrile wiper with a finger spring to act as a chip guard. The metal insert is 20 ga. galvanized steel and the guard is .01 in. thick spring steel.

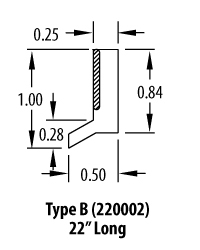

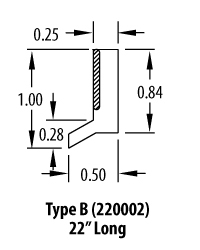

- Type B (part no. 220002) – Molded nitrile wiper with metal strip bonded to one side. The metal insert is 20 ga. galvanized steel.

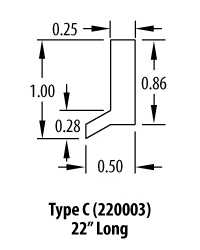

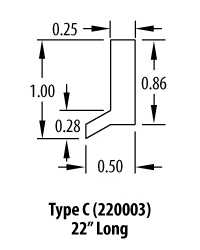

- Type C (part no. 220003) – Molded nitrile wiper only. Metal mounting plate recommended.

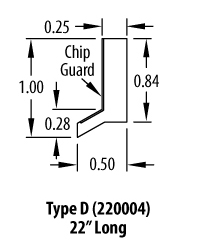

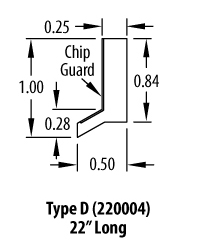

- Type D (part no. 220004) – Molded nitrile wiper with light metal strip which acts as finger spring and chip guard. The metal insert is 20 ga. galvanized steel and the guard is .01 in. thick spring steel

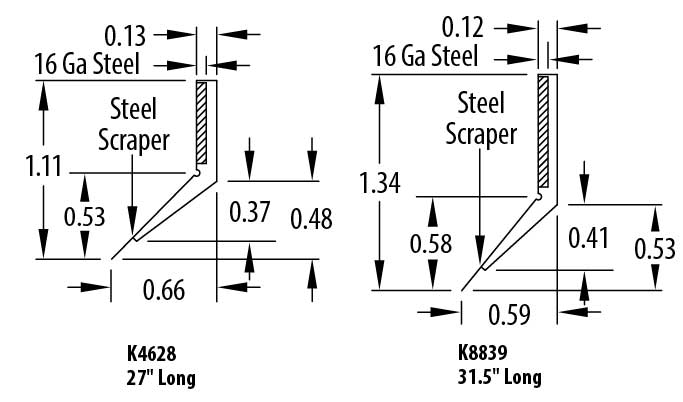

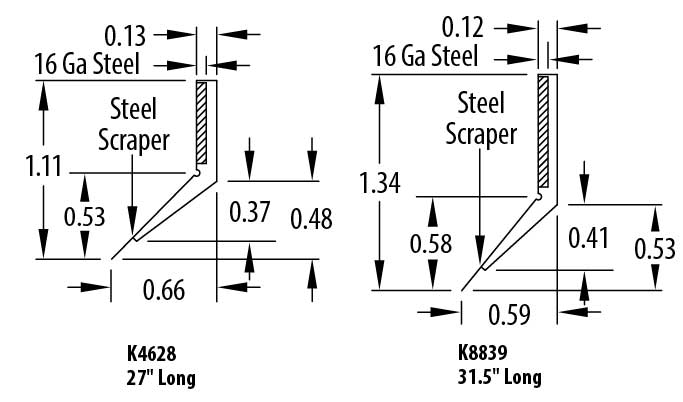

Steel Edge Knee Wipers

The oil resistant nitrile (Buna-N) rubber wiper includes a molded in steel mounting plate plus a thin spring-steel guard along the length of the wiping edge. The wiper be used as a wiper or a light-duty scraper on uneven sheet metal applications. The wiper can be easily cut to the required length, and over-sized holes may be drilled for easy installation and adjustment.

Download PDF

- K4628 – Available in 27” lengths

- K8839 – Available in 31.5” Lengths

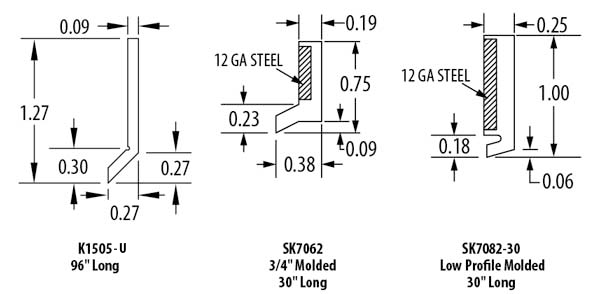

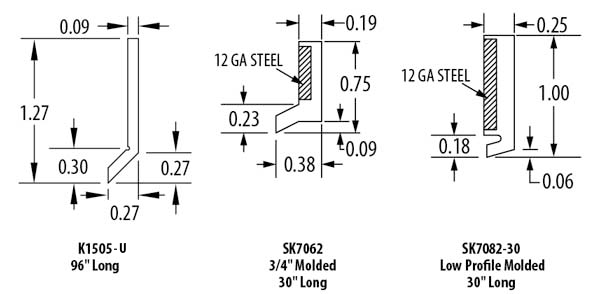

Additional Stock Wiper Profiles

- Part no. K1505-U – 96” Long

- Part no. SK7062 – 3/4” Molded – 30” Long

- Part no. SK7082-30 – Low Profile Molded – 30” Long

Download PDF

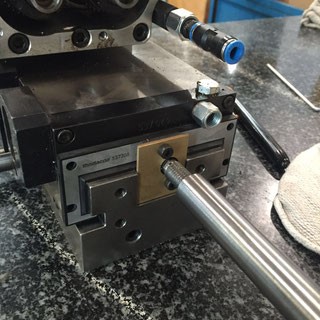

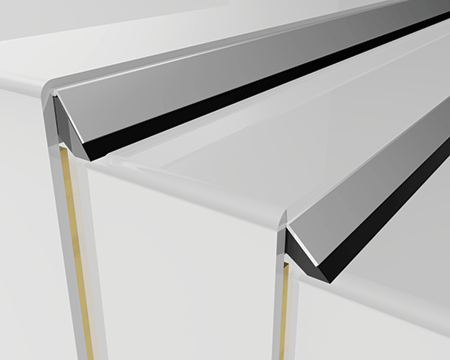

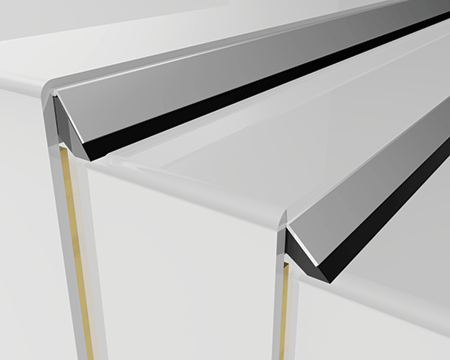

Telescopic Wipers

Wipers Combinations

Call for pricing. Download PDF for dimensional drawings

Photo: Brass Bar

Custom Wipers

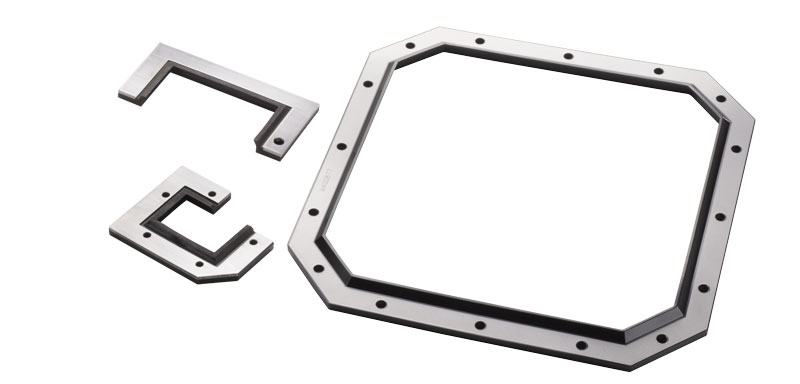

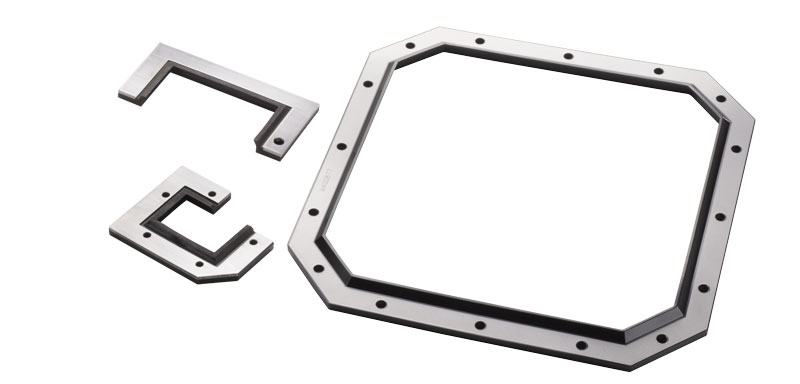

Custom-Molded Way Wipers

Dynatect’s wipers are compression molded as a single piece with incorporated metal inserts. The wiping surface is molded with Nitrile (Buna-N) which offers improved resistance to abrasion, oil, and hydraulic fluids. Nitrile has compatibility with a wider variety of cutting fluids and coolants used in typical applications, including the use of synthetic fluids. This material can perform well in both wet and dry application.

Dynatect has hundreds of wiper designs and standard profiles to choose from to fit a variety of applications. Dynatect’s engineering team will select one that best matches your needs or closely matches the sample or drawing you provide.

Molded way wipers are ideal for medium to high volumes and OEM applications (a nominal tooling charge is required for new designs).

Request a Quote

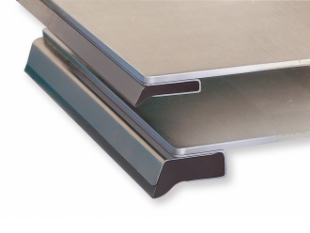

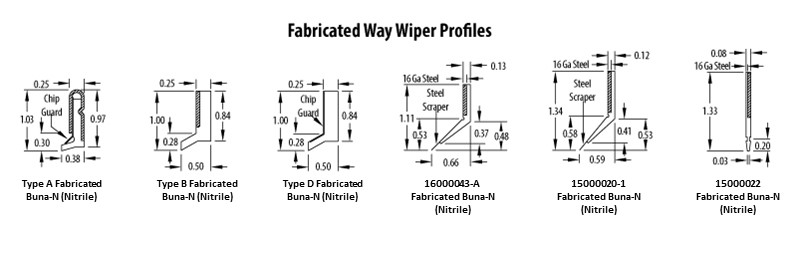

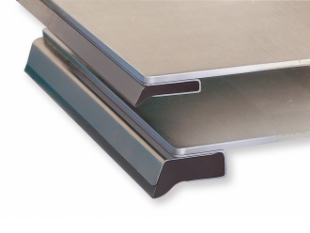

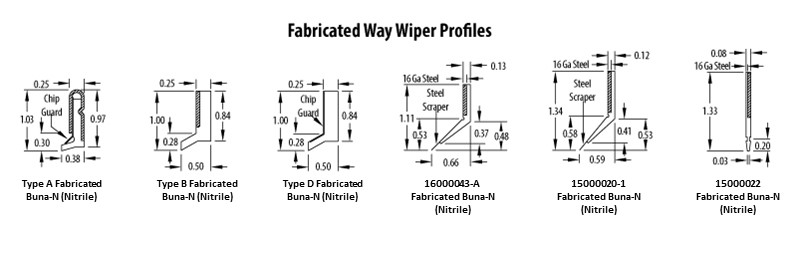

Custom-Fabricated Way Wipers

Fabricated way wipers are ideal for low to moderate volumes, typically used in maintenance and repair applications. They are fabricated from corners and straight lengths of standard molded wipers, and are tooling free. The rubber wiping surface is made of Nitrile (Buna-N)

Several standard profiles are available (see below), but these two are the most common:

1. Type A Profile – For heavy chip loads and coolants. Fully enclosed in a metal channel with spring-steel chip guard.

2. Type B Profile – Large wiping edge for heavy coolant applications.

Both styles are supplied with mounting plates for easy installation. If what you need is not shown, just ask. Dynatect can make most shapes. Send a drawing of your custom profile or contact us for instructions on sending in your wiper product for quoting.

Standard Profiles/Cross-Sections:

Note: When fabricated, Type A, Type B, and Type D wipers will include a 16GA cover plate. Custom profiles are available.

Request a Quote

Materials Data Sheets

Dynatect now has the capabilities to produce all way wiper products using Nitrile, therefore existing Polyurethane wipers will transition to Nitrile effective January 2021. Dynatect continues to be able to provide wipers in flouroelastomer/FPM when the environment dictates.

Nitrile (NBR) provides the following advantages:

- Improved resistance to abrasion, oil, and hydraulic fluids

- Better compatibility with a wider variety of cutting fluids

- Superior performance in “dry” machining applications. Nitrile has a lower coefficient of friction compared to polyurethane.

Flouroelastomer (FPM) is a performance rubber that is highly resistant to acids and extreme high temperatures to 410º F / 210º C

Material Data Sheets: